- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-03-05 Origin: Site

Introduction

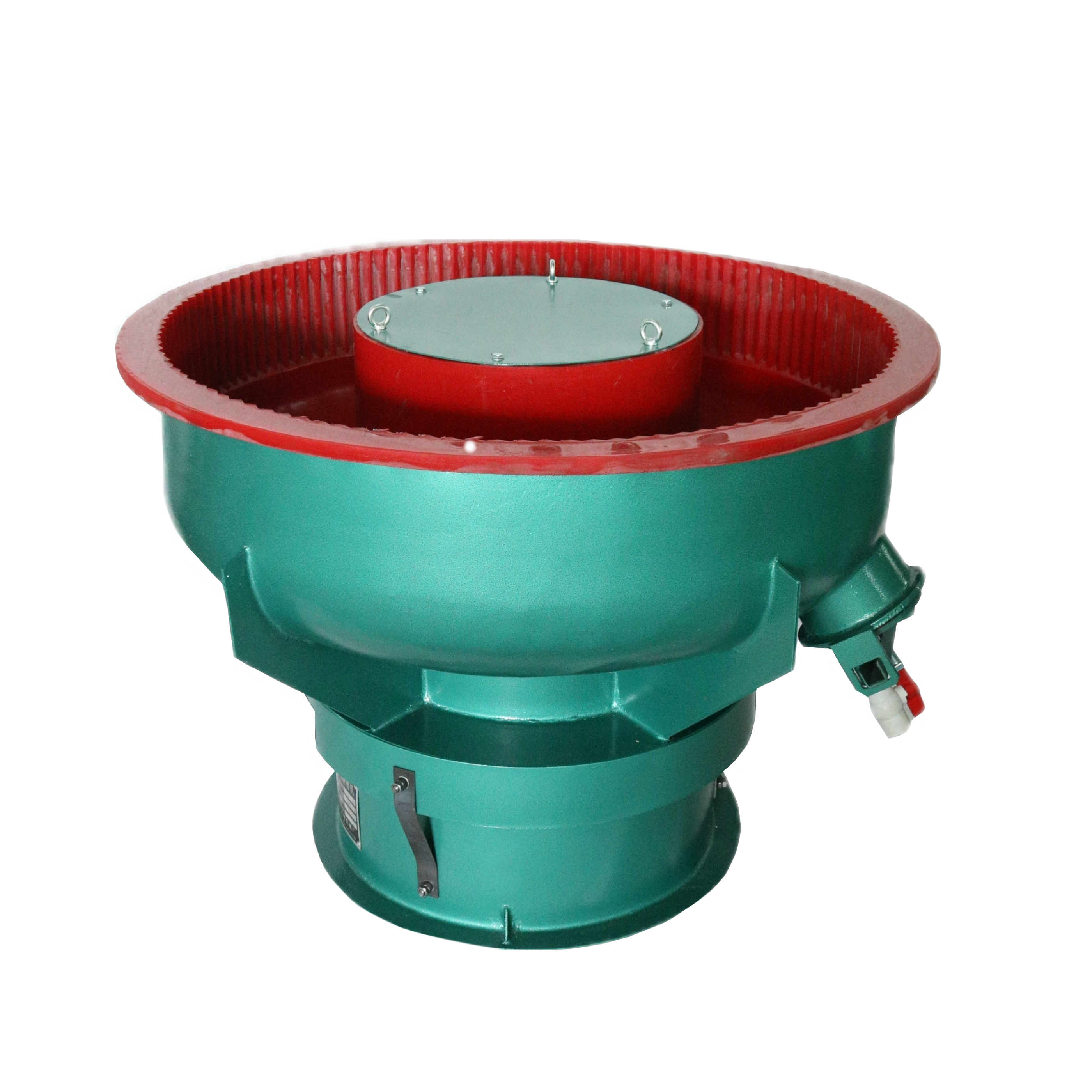

Vibratory polishing machine operates on the principle of generating three-dimensional high-frequency vibrations within a ring chamber, where the grinding media and parts are contained. These vibrations cause the parts and the tumbling polishing media to move in one direction, resulting in friction that facilitates surface finishing. After polishing, the original shape and dimensional accuracy of the parts are not damaged, the internal stress of the parts can be eliminated, thereby achieving a certain level of finishing, smoothness, and brightness on the surface of the part.

Vibratory polishing machine mainly includes three parts: inertial vibrator, vessel and basement. The color of the outside of the machine is green, and the PU material inside is red. Please let us know if you prefer other colors.

1.Inertial vibrator: it serves as the vibrating source, comprising a vibratory motor, springs, and eccentric blocks. The inertial vibrator can effectively eliminates burrs, sharp edges, edges, rust, oil stains, etc., so that the surface of the part reaches a certain degree of polishing.

2.Vessel: it is constructed by welding annular steel plates together and is lined with high-quality polyester PU to minimize noise and the impact of your products.

3.Basement: Constructed from welded steel, the basement incorporates springs to securely hold the vessel.

The using method of this product is very simple. The parts requiring polishing can be placed in a container equipped with polishing media beforehand. Through the consistent vibration of the container, it effectively eliminates burrs, sharp edges, corners, rust, oil stains, etc., thereby achieving a certain level of finishing, smoothness, and brightness on the surface of the part.

Outstanding Advantages

Vibratory polishing machines have the following excellent performance.

Firstly, the inner liner is made of Polyester PU, which is a kind of high wear-resistant and corrosion-resistant material and is poured in one time. It can avoid piece stick to wall and reduce working noise and make the machine have long service life.

Secondly, the inner spring helps to drives the vibration of the machine to polish and reduce the crash between media and machine.

Thirdly, the whole machine steel plate is thickened to make the machine stability is better. The load capacity is obviously improved, and the machine shell is not easy to crack.

Lastly, the polishing process does not destroy the original size and shape of your parts. Our machine can achieve automation, unmanned operation and easy to operate. In the process of work, you can check the processing of the parts at any time.

40A

60A

80A

95A

150A

250A

350A

450A

650A

950

Features

1. Effectively reduce working noise.

2. Large loading capacity and wide application range.

3. Manually separate polishing media and products.

4. Automated, unmanned operation.

5. Does not destroy the original size and shape of the part.

6. Suitable for large quantities of small and medium size parts finishing processing.

Wide Application

Vibratory polishing machine can be applied to the surface polishing, chamfering, deburring, polishing and brightening of various size parts in mass production. It does not affect the original dimensional accuracy of the product after treatment. It also can eliminate the internal stress of the parts and provide the surface finish of the product. This lays a good foundation for some products subsequent electroplating, spraying and other surface treatment.

1. Jewelry polishing: such as pendants, earrings, necklaces, rings, chains, bracelets, pearls, silverware etc.

2. Cutlery polishing, such as spoons, forks and knives.

3. Rust removal and deburring hardware tools

4. Electronic components finishing

5. Plastic deburring

6. Ceramic jade polishing

7. Laser cut parts polishing

8. 3D print parts polishing

Factory Production

Norden machinery has rich manufacturing experience in vibratory polishing machine for more than 20 years. Our vibratory polishing machine not only have excellent performance, but also contain deep care for users. We can provide you with product customization services. We will try our best to help you make the color or special shape you like. If you have any special customization needs, you can tell us. We hope that our products can help you in your business.