- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-03-04 Origin: Site

Introduction

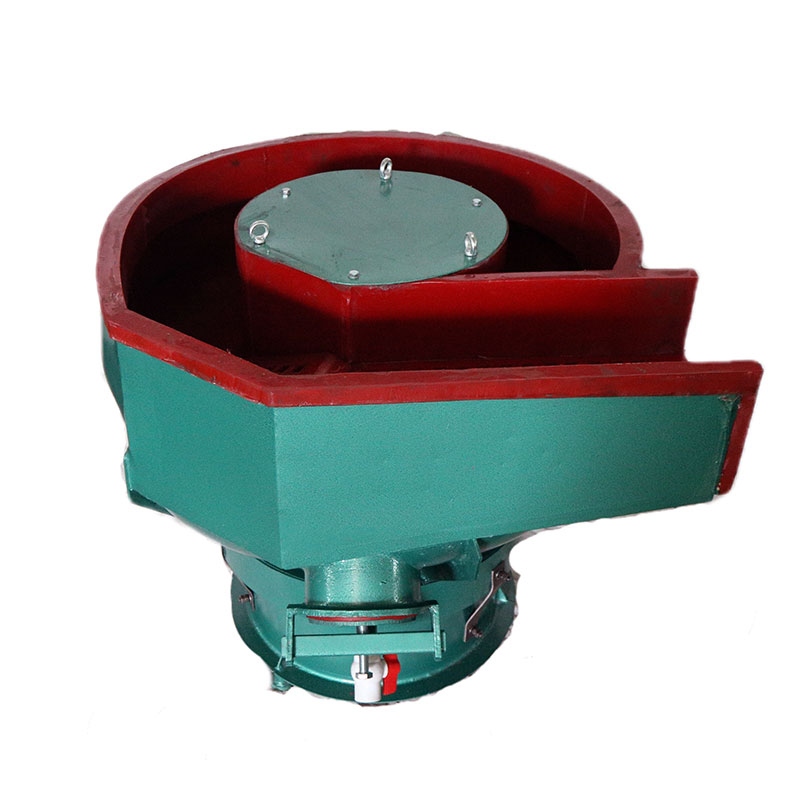

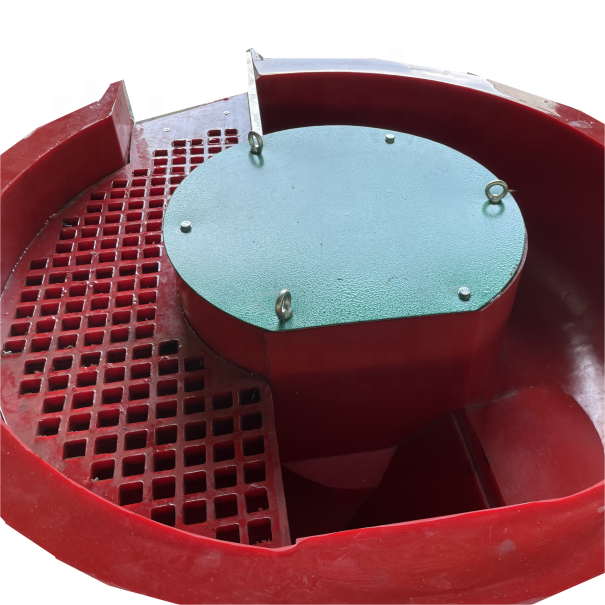

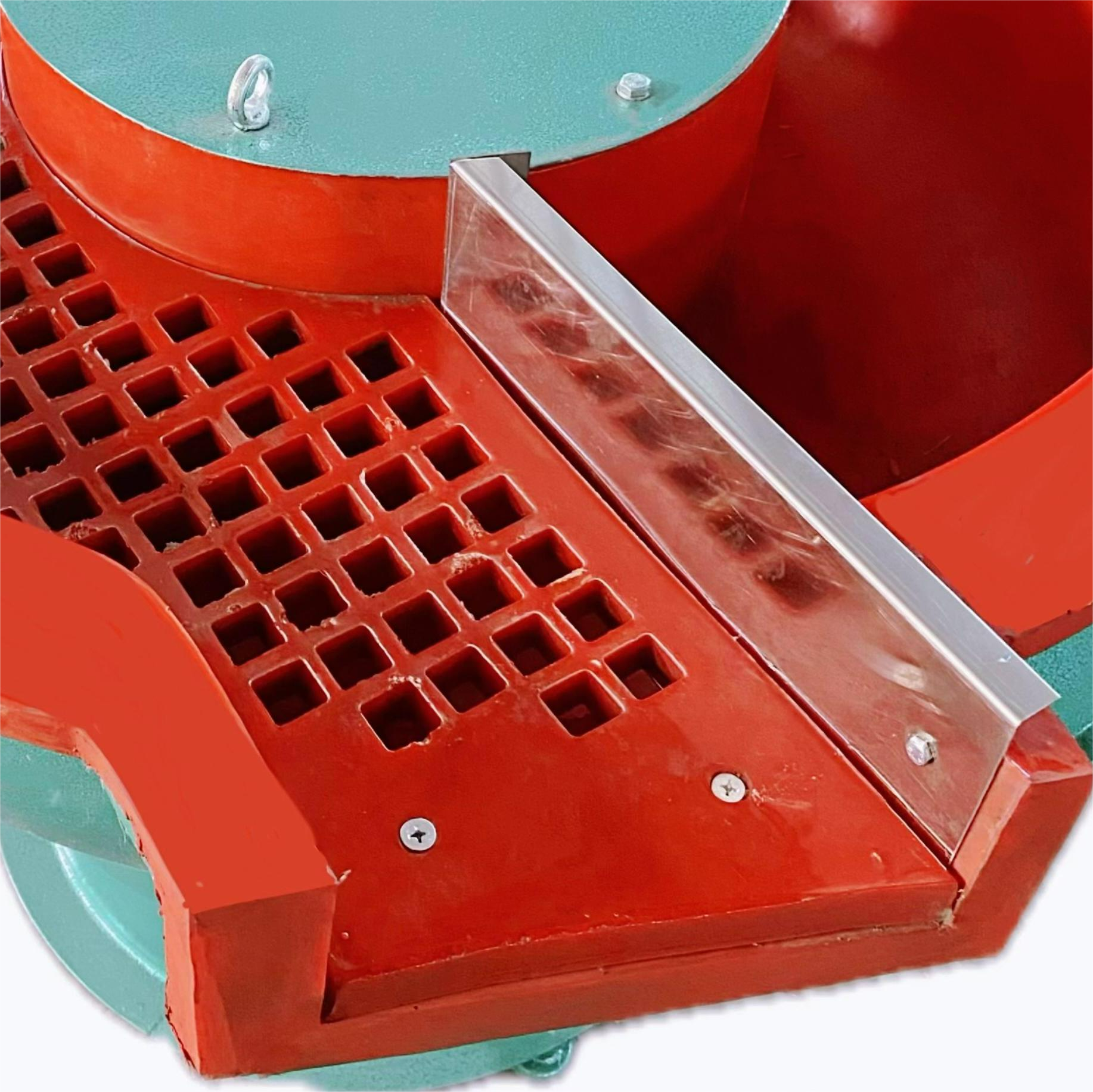

Vibratory polishing machine with separator works on the similar working principle with normal vibratory polishing machine. It adopts the principle of generating three-dimensional high-frequency vibrations within a ring chamber. These vibrations cause the parts and the tumbling polishing media to move in one direction, resulting in friction that facilitates surface grinding. In the structure mainly includes inertial vibrator, vessel and basement. It features a climbing plate with holes and withdrawal on the inside of the machine. It needs to be taken out during the grinding process. After your products meets the polishing requirements, it needs to be put into the shipment portion. And then the products and tumbling polishing media will be automatically separated.

Vibratory Polishing Machine with Separator

Curved Vibratory Polishing Machine with Separator

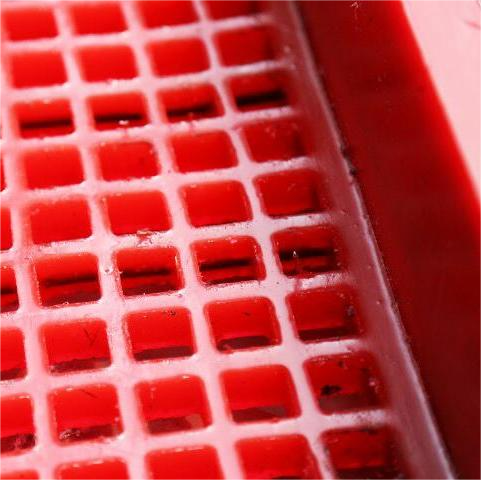

In the structure mainly includes inertial vibrator, vessel and basement. It features a climbing plate with holes and withdrawal on the inside of the machine. It needs to be taken out during the grinding process. After your products meets the polishing requirements, it needs to be put into the shipment portion. And then the products and tumbling polishing media will be automatically separated.

Outstanding Advantages

Norden machinery has been committed to producing high performance polishing products to bring happy shopping experience to every customer. We have been trying to develop a better polishing machine. The whole machine steel plate is thickened to make the machine stability is better. The load capacity is significantly improved to keep the machine shell is not easy to crack. The machine is made of high wear-resistant and corrosion-resistant material. This material can extend the service life while avoiding collisions between parts and reducing noise. Our machine can achieve automation, unmanned operation. In the process of polishing, you can check the parts condition at any time.

Features

Automatic separation of tumbling polishing abrasive and products.

Large loading capacity and wide application range.

Obviously improve the surface finish and precision of the parts.

Does not destroy the original size and shape of your product.

Suitable for batch small and medium size parts polishing processing.

Wide Application

Vibratory polishing machine with separator cover can be applied to the surface polishing, chamfering, deburring, polishing and brightening of various size parts in mass production. It does not affect the original dimensional accuracy of the product after treatment. It also can eliminate the internal stress of the parts and provide the surface finish of the product. This lays a good foundation for some products subsequent electroplating, spraying and other surface treatment.

1. Jewelry polishing, such as pendants, earrings, necklaces, rings, chains, bracelets, pearls, silverware.

2. Cutlery polishing, such as spoons, forks and knives.

3. Rust removal and deburring hardware tools

4. Electronic components finishing

5. Plastic deburring

6. Ceramic jade polishing

7. Laser cut parts polishing

8. 3D print parts polishing

Factory Production

Norden machinery has been developing and producing polishing machines for more than 20 years. Our vibratory polishing machine not only have excellent performance, but also contain deep care for users. We can provide you with product customization services. The color of the outside of the machine is green, and the PU material inside is red. If you have any special color or shape customization needs, please can contact us. We will try our best to meet your needs. We hope that our products can help you in your business.