- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

70L

Norden

|

Product Description

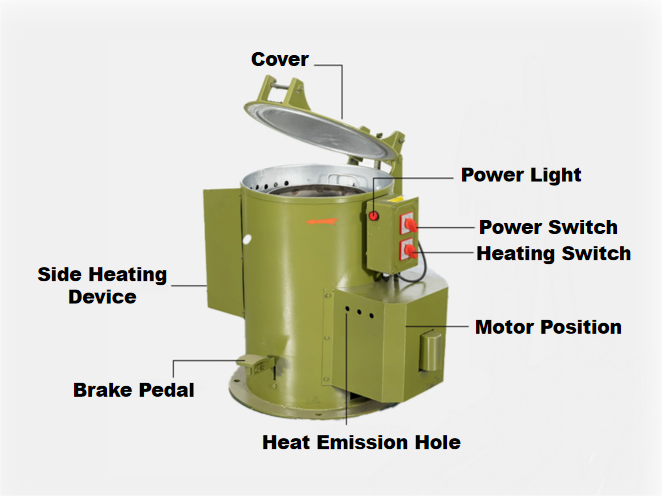

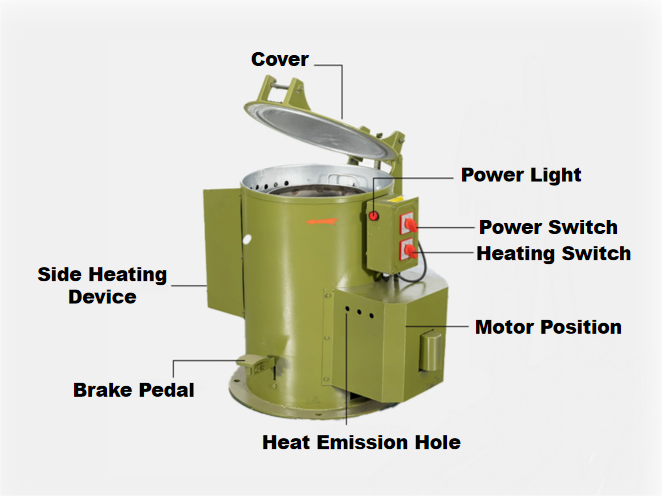

Centrifugal dryer machine uses The principle of centrifugal hot air drying is applied to achieve dehydration and drying to avoid product rust or oxidation. It uses centrifugal force to remove the liquid attached to the surface of the products, so that the wet material is fluid-bed drying in the centrifugal force field.

The cleaned product is put into the inner barrel and heated through the electric heat pipe. The high temperature generated after heating passes through the air extraction device at the lower part of the high-speed rotating stainless steel inner barrel. Then those hot air is sucked into the cylinder. The inner barrel rotates while drying the surface water and oil stains of the product, so as to achieve the effect of dehydration, oil removal and drying. Centrifugal dryer machine is a combination of dehydration and drying machine.

Centrifugal dryer machine from Norden has the following high performance.

1. Inner tumbler: Can be removed, easy to install and take.

2. Heating direction: Rapid heating, circulating hot air centrifugal rotation.

3. Brake pedal: With foot brake device, can quickly stop the tumbler.

4. Switch: Easy to operate, simple and durable.

Brake Pedal

Fan Blade

Heating Tube

Dehydrating Tumbler

*We can also provide you with the above centrifugal dryer machines.

|

Feature

1.Using the principle of centrifugal drying, the drying efficiency is high.

2.With foot brake device, can quickly stop the cylinder.

3.The container is made of stainless steel for long service life.

4.Dryer machines are small and take up limited space.

5.Equipped with advanced control system, can achieve automatic temperature control and automatic timing.

6.Automatically complete the entire drying process, without manual guard, greatly saving labor costs and time costs.

7.The automatic control can also ensure the stability and consistency of the drying process.

8.A large amount of water in the material is removed in a relatively short period of time.

|

Application

Centrifugal dryer machine is suitable for products that need to be dehydrated, dried and oil dumped. It has a wide application in many industries.

Foods: Egg powder, condiments, protein, milk powder, coffee, tea, glucose, vegetable juice, yeast, starch, etc.

Ceramics: Clay, various ferrite and metal oxides, etc

Chemicals: disperse dyes, reactive dyes, organic catalysts, white carbon black, washing powder, inorganic catalysts, all kinds of waste liquid, etc

|

Size Information

Here is the general centrifugal dryer machine parameter information. We truly hope that our centrifugal polishing machine can help you in your business.

| MACHINE MODEL | ND-35L | ND-70L |

| L*W*H | 800*700*800MM | 1000*800*850MM |

| DRUM SIZE | Φ400*300MM | Φ500*400MM |

| DRUM OUTLET APERTURE | Φ3MM | Φ4MM |

| DRUM LOAD | 35KG | 70KG |

| ROTATING SPEED | 630RPM | 530RPM |

| MOTOR POWER | 0.75KW | 1.1KW |

| HEATING WIRE POWER | 3KW | 3KW |

| LINER OUTLET APERTURE | 0.75KW | 0.75KW |

| VOLTAGE | 380V/220V | 380V/220V |

Method of use:

1.Before starting the machine, check whether the power supply is engaged and the fixed position of the tumbler is correct. Then connect the power supply, open the top cover, switch on the motor switch, and let the tumbler run idling. The direction of the steering should be the same as that of the arrow in the housing.Then switch on the electric heating wire, hot air can be discharged after a few minutes. If the hot air is not discharged after 5 minutes of work, stop the machine to check whether the exhaust outlet of the hot wire is blocked.

2.The machine should be covered during the dehydration process, and the inner tumbler should be stopped when loading and unloading. Note that the material in the inner tumbler should be evenly divided when it is removed, otherwise it will shake violently because of the imbalance of centrifugal force.

3.Before stopping, you need to power off and then brake, do not brake without power. The dehydrator can only dehydrate without heating, but it can not only heat without allowing the motor to rotate.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment.We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Centrifugal dryer machine uses The principle of centrifugal hot air drying is applied to achieve dehydration and drying to avoid product rust or oxidation. It uses centrifugal force to remove the liquid attached to the surface of the products, so that the wet material is fluid-bed drying in the centrifugal force field.

The cleaned product is put into the inner barrel and heated through the electric heat pipe. The high temperature generated after heating passes through the air extraction device at the lower part of the high-speed rotating stainless steel inner barrel. Then those hot air is sucked into the cylinder. The inner barrel rotates while drying the surface water and oil stains of the product, so as to achieve the effect of dehydration, oil removal and drying. Centrifugal dryer machine is a combination of dehydration and drying machine.

Centrifugal dryer machine from Norden has the following high performance.

1. Inner tumbler: Can be removed, easy to install and take.

2. Heating direction: Rapid heating, circulating hot air centrifugal rotation.

3. Brake pedal: With foot brake device, can quickly stop the tumbler.

4. Switch: Easy to operate, simple and durable.

Brake Pedal

Fan Blade

Heating Tube

Dehydrating Tumbler

*We can also provide you with the above centrifugal dryer machines.

|

Feature

1.Using the principle of centrifugal drying, the drying efficiency is high.

2.With foot brake device, can quickly stop the cylinder.

3.The container is made of stainless steel for long service life.

4.Dryer machines are small and take up limited space.

5.Equipped with advanced control system, can achieve automatic temperature control and automatic timing.

6.Automatically complete the entire drying process, without manual guard, greatly saving labor costs and time costs.

7.The automatic control can also ensure the stability and consistency of the drying process.

8.A large amount of water in the material is removed in a relatively short period of time.

|

Application

Centrifugal dryer machine is suitable for products that need to be dehydrated, dried and oil dumped. It has a wide application in many industries.

Foods: Egg powder, condiments, protein, milk powder, coffee, tea, glucose, vegetable juice, yeast, starch, etc.

Ceramics: Clay, various ferrite and metal oxides, etc

Chemicals: disperse dyes, reactive dyes, organic catalysts, white carbon black, washing powder, inorganic catalysts, all kinds of waste liquid, etc

|

Size Information

Here is the general centrifugal dryer machine parameter information. We truly hope that our centrifugal polishing machine can help you in your business.

| MACHINE MODEL | ND-35L | ND-70L |

| L*W*H | 800*700*800MM | 1000*800*850MM |

| DRUM SIZE | Φ400*300MM | Φ500*400MM |

| DRUM OUTLET APERTURE | Φ3MM | Φ4MM |

| DRUM LOAD | 35KG | 70KG |

| ROTATING SPEED | 630RPM | 530RPM |

| MOTOR POWER | 0.75KW | 1.1KW |

| HEATING WIRE POWER | 3KW | 3KW |

| LINER OUTLET APERTURE | 0.75KW | 0.75KW |

| VOLTAGE | 380V/220V | 380V/220V |

Method of use:

1.Before starting the machine, check whether the power supply is engaged and the fixed position of the tumbler is correct. Then connect the power supply, open the top cover, switch on the motor switch, and let the tumbler run idling. The direction of the steering should be the same as that of the arrow in the housing.Then switch on the electric heating wire, hot air can be discharged after a few minutes. If the hot air is not discharged after 5 minutes of work, stop the machine to check whether the exhaust outlet of the hot wire is blocked.

2.The machine should be covered during the dehydration process, and the inner tumbler should be stopped when loading and unloading. Note that the material in the inner tumbler should be evenly divided when it is removed, otherwise it will shake violently because of the imbalance of centrifugal force.

3.Before stopping, you need to power off and then brake, do not brake without power. The dehydrator can only dehydrate without heating, but it can not only heat without allowing the motor to rotate.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment.We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case