- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

120L

Norden

|

Product Description

Centrifugal disc polishing machine adopts the advanced whirl type rotary tumbling mode. Through the centrifugal force generated by the rotating disc, the products and tumbling polishing abrasives in the grinding barrel produce high-speed rotating friction with the barrel wall. At the same time, due to the special structure of zigzag shape of the grinding barrel wall, the products and tumbling polishing abrasives produce tumbling action while rotating at high speed.This helps to speed up the cutting force between the products and the abrasives, thereby increasing the grinding and polishing efficiency. And it can effectively avoid products overlap, unequal grinding problems.

Vertical Type

Horizontal Type

Norden machinery has rich manufacturing experience in centrifugal disc polishing machine. In order to solve the polishing needs of many customers, we have been committed to researching various polishing equipment. We hope our polishing equipment will give you a pleasant polishing experience and promote your career. Centrifugal disc polishing machine has the following excellent performances.

All copper core motor: Using special vibration motor with lower failure rate and more stable performance.

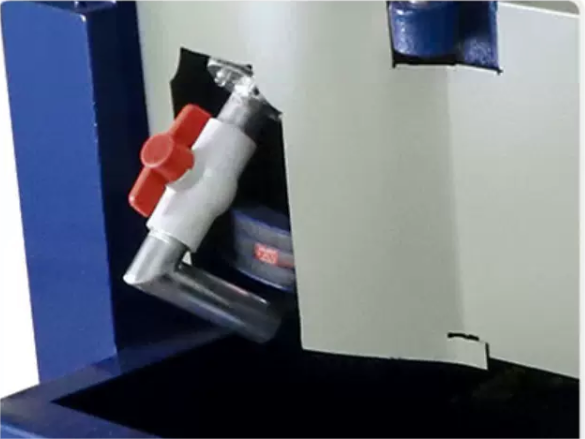

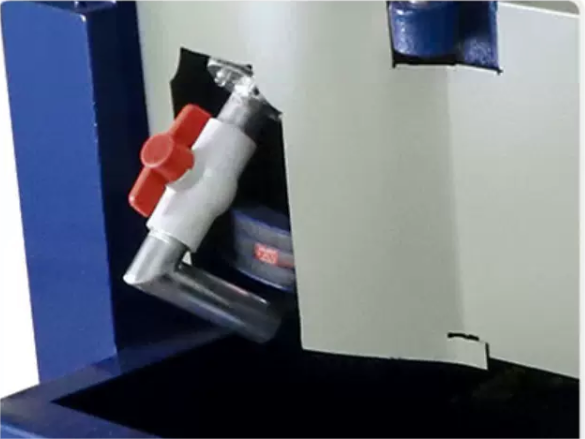

Water outlet and discharge port: The bottom of the machine is provided with a water outlet and a discharge port. It is easy to use to improve work efficiency.

No damage to products:The inner lining of the machine is PU material which is more resistant to corrosion and wear. The original size and shape of the parts are not damaged during polishing processing.

Using the principle of eddy flow. The polishing efficiency is superior and the working efficiency is increased by 15~30 times.

Using the variable frequency speed regulation which is more safe and durable. The rotary speed can be selected according to the grinding requirements.

Easy to operate: Our machine can realize automated and unmanned operation. You can spot check the polishing processing of products at any time.

EASY TO OPERATE

Automated and unmanned operation; You can spot check the processing of parts at any time

WATER OUTLET AND

DISCHARGE PORT

Easy to use to improve work efficiency; The bottom of the machine is provided with a water outlet and a discharge port

NO DAMAGE TO PARTS

LINING PU MATERIAL

More resistant to corrosion and wear; The original size and shape of the parts are not damaged during processing

ALL COPPER CORE MOTOR

Using Special Vibration Motor; Lower failure rate and more stable performance

| Feature

1.Achieve automation, no manual operation and easy to operate.

2.Can automatically pour products, save labor cost and cost-effective.

3.Select frequency control function for surface treatment of small parts.

4.The speed of the turntable can be selected according to the polishing need. You can spot check the processing of parts at any time.

5.The fixed groove and the turntable are lined with polyurethane rubber, which has high strength, good wear resistance and long service life.

6.Can Select stainless steel polishing media to reduce the gap and prevent thin product jams.

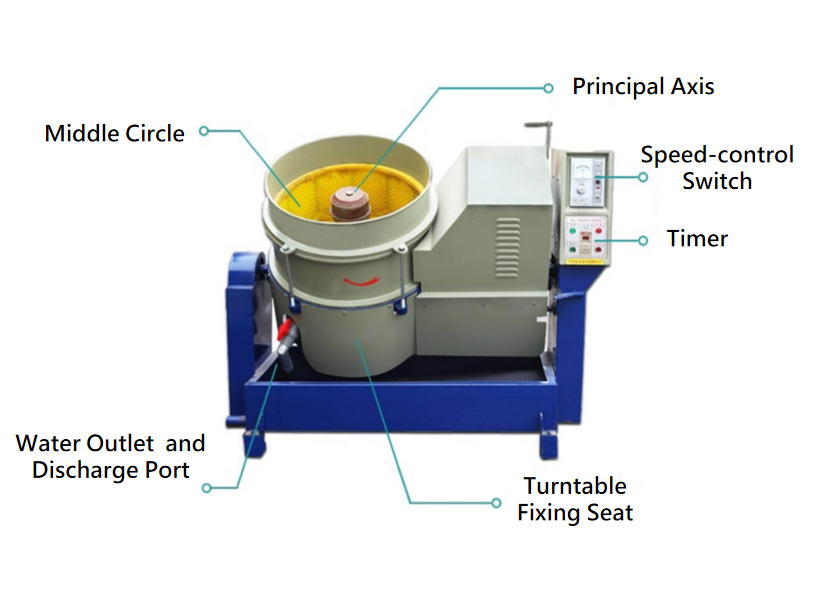

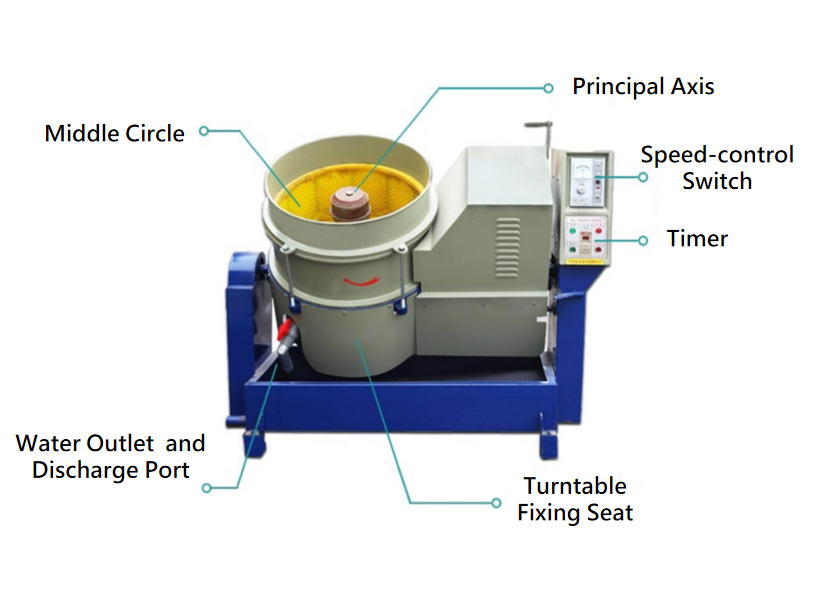

Principal Axis

Turntable Fixing Seat

Middle Circle

Turnplate

|

Application

Centrifugal disc polishing machine is suitable for the surface precision polishing treatment of medium and small parts with complex shape, large burr and thick oxide skin. Hardware accessories, medical supplies, electronic products, automotive and motorcycle accessories are widely used in various industries of metal, some non-metallic materials of stamping parts, mechanical workpiece, casting and forging, heat treatment and other workpiece deburring, chamfering, oxidation, polishing and other processes, you can choose this machine.

|

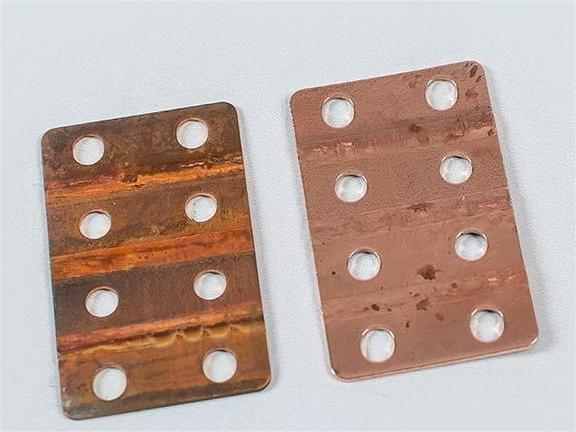

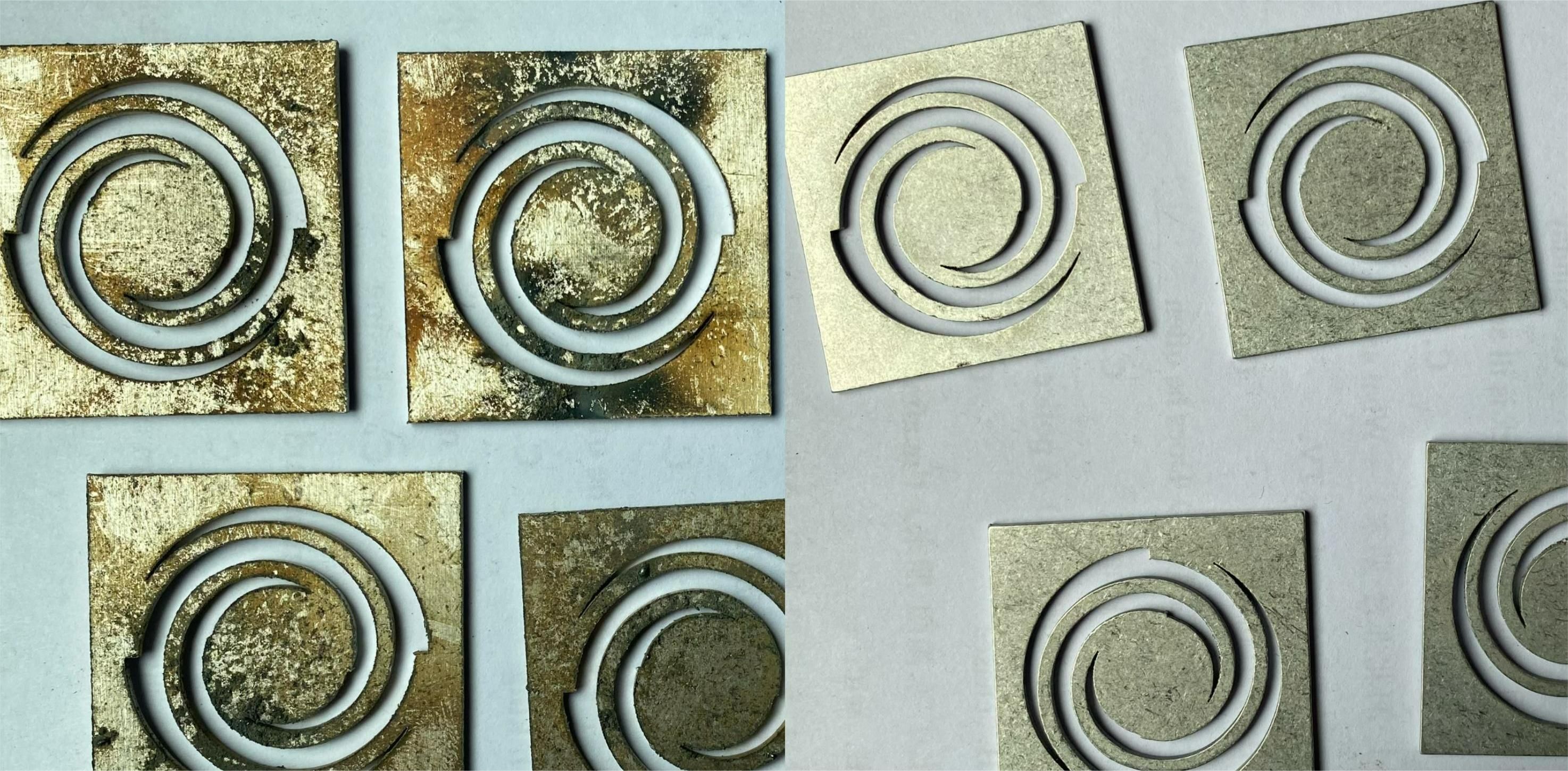

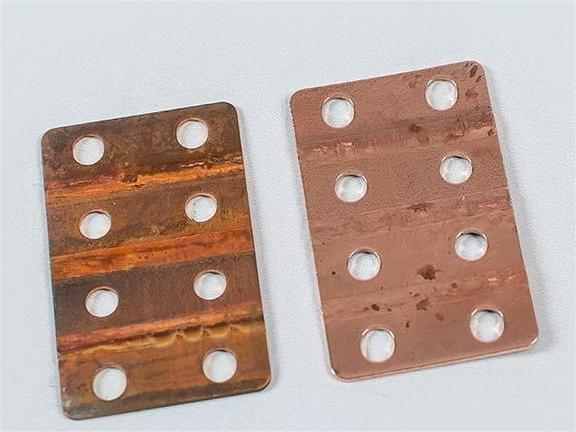

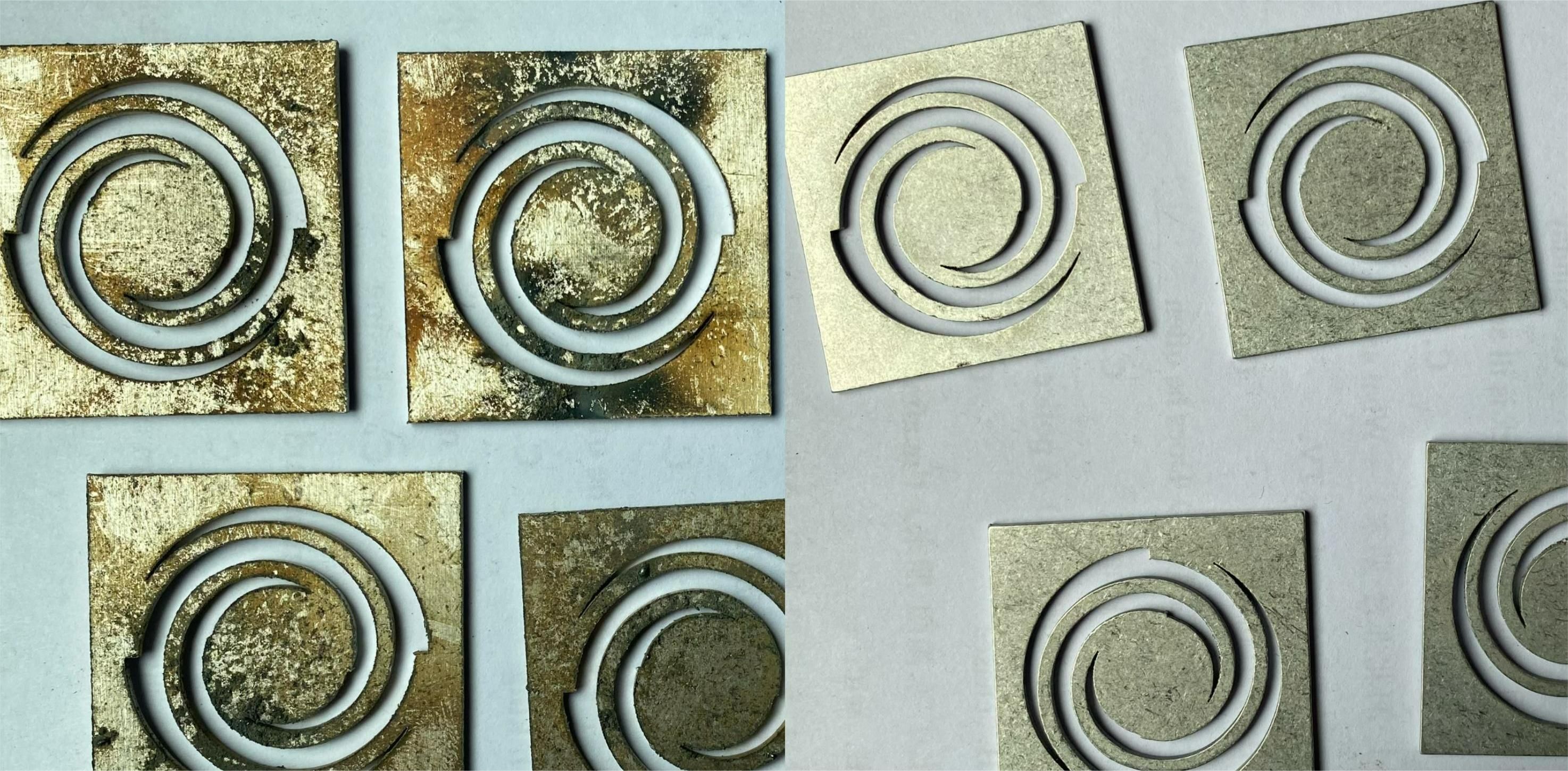

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general centrifugal disc polishing machine parameter information.

We truly hope that our centrifugal polishing machine can help you in your business.

| Model | ND-50L | ND-120L |

| Capacity(L) | 50 | 120 |

| Size(MM) | 1100*750*1200 | 1200*1200*1100 |

| Speed(RPM) | 220 | 220 |

| Power(KW) | 1.5 | 4 |

| Chamber dimension (MM) | 480 | 690 |

| Weight(KG) | 300 | 700 |

| PU Thickness(MM) | 20 | 25 |

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Centrifugal disc polishing machine adopts the advanced whirl type rotary tumbling mode. Through the centrifugal force generated by the rotating disc, the products and tumbling polishing abrasives in the grinding barrel produce high-speed rotating friction with the barrel wall. At the same time, due to the special structure of zigzag shape of the grinding barrel wall, the products and tumbling polishing abrasives produce tumbling action while rotating at high speed.This helps to speed up the cutting force between the products and the abrasives, thereby increasing the grinding and polishing efficiency. And it can effectively avoid products overlap, unequal grinding problems.

Vertical Type

Horizontal Type

Norden machinery has rich manufacturing experience in centrifugal disc polishing machine. In order to solve the polishing needs of many customers, we have been committed to researching various polishing equipment. We hope our polishing equipment will give you a pleasant polishing experience and promote your career. Centrifugal disc polishing machine has the following excellent performances.

All copper core motor: Using special vibration motor with lower failure rate and more stable performance.

Water outlet and discharge port: The bottom of the machine is provided with a water outlet and a discharge port. It is easy to use to improve work efficiency.

No damage to products:The inner lining of the machine is PU material which is more resistant to corrosion and wear. The original size and shape of the parts are not damaged during polishing processing.

Using the principle of eddy flow. The polishing efficiency is superior and the working efficiency is increased by 15~30 times.

Using the variable frequency speed regulation which is more safe and durable. The rotary speed can be selected according to the grinding requirements.

Easy to operate: Our machine can realize automated and unmanned operation. You can spot check the polishing processing of products at any time.

EASY TO OPERATE

Automated and unmanned operation; You can spot check the processing of parts at any time

WATER OUTLET AND

DISCHARGE PORT

Easy to use to improve work efficiency; The bottom of the machine is provided with a water outlet and a discharge port

NO DAMAGE TO PARTS

LINING PU MATERIAL

More resistant to corrosion and wear; The original size and shape of the parts are not damaged during processing

ALL COPPER CORE MOTOR

Using Special Vibration Motor; Lower failure rate and more stable performance

| Feature

1.Achieve automation, no manual operation and easy to operate.

2.Can automatically pour products, save labor cost and cost-effective.

3.Select frequency control function for surface treatment of small parts.

4.The speed of the turntable can be selected according to the polishing need. You can spot check the processing of parts at any time.

5.The fixed groove and the turntable are lined with polyurethane rubber, which has high strength, good wear resistance and long service life.

6.Can Select stainless steel polishing media to reduce the gap and prevent thin product jams.

Principal Axis

Turntable Fixing Seat

Middle Circle

Turnplate

|

Application

Centrifugal disc polishing machine is suitable for the surface precision polishing treatment of medium and small parts with complex shape, large burr and thick oxide skin. Hardware accessories, medical supplies, electronic products, automotive and motorcycle accessories are widely used in various industries of metal, some non-metallic materials of stamping parts, mechanical workpiece, casting and forging, heat treatment and other workpiece deburring, chamfering, oxidation, polishing and other processes, you can choose this machine.

|

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general centrifugal disc polishing machine parameter information.

We truly hope that our centrifugal polishing machine can help you in your business.

| Model | ND-50L | ND-120L |

| Capacity(L) | 50 | 120 |

| Size(MM) | 1100*750*1200 | 1200*1200*1100 |

| Speed(RPM) | 220 | 220 |

| Power(KW) | 1.5 | 4 |

| Chamber dimension (MM) | 480 | 690 |

| Weight(KG) | 300 | 700 |

| PU Thickness(MM) | 20 | 25 |

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case