- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ND-01

Norden

|

Product Description

Norden machinery is one of the companies with a wide range of tumbling polishing medias and brighteners in the global market. After more than 20 years of continuous exploration and improvement, we now have grinding media including: plastic media, ceramic media, brown corundum, stainless steel media and various brighteners. According to the various needs of different customers around the world, we are constantly developing new tumbling media to meet customer needs and constantly solving various surface polishing and deburring treatment problems.

Ceramic media is a new kind of grinding material, which has many excellent properties and is widely used in grinding, polishing and other fields. It is mainly based on alumina and other ceramic materials, and is prepared by special process treatment and adding some auxiliary ingredients (such as additives, crystal seeds, etc.). These additives can improve the performance of abrasives, such as increasing hardness, self-sharpness and so on.

We have two main types of ceramic porcelain polishing media: the standard porcelain tumbling media with alumina content of 30-40% and the fine porcelain tumbling media with alumina content of 70%. Porcelain tumbling media is sturdy and robust media. It can be used either in an industrial vibratory tumbler bowl or high energy centrifugal disc finishing machine.

Triangle(SCT)

Ball

Cylinder(ACC)

Triangle(ACT)

|

Feature

1. The hardness of ceramic media is usually high. It has no fragmentation and low wear during use. And it has excellent cutting performance. The surface is not blocked, and the polishing ability is strong. It can effectively grind a variety of materials.

2. Compared with traditional polishing abrasives, ceramic abrasives have better toughness. It is not easy to break during grinding and deburring process and can maintain better grinding shape and dimensional accuracy.

3. In the grinding process, the surface of the ceramic abrasive will constantly form a new sharp cutting edge to maintain a good polishing performance. So it helps to reduce the need for frequent replacement due to ceramic media blunting and improves the service life of the ceramic polishing media.

4. Ceramic abrasive can maintain good performance in high temperature environment. It is not easy to change performance or damage due to high temperature. So it is suitable for high-speed grinding and high temperature processing and other occasions.

| Application

Ceramic media has a wide application in various industries.

1.Machining process: It is suitable for deburring, grinding and polishing of metal materials, such as parts processing in automotive, aerospace, machinery manufacturing and other industries.

2.Electronics industry: In the manufacturing process of semiconductors and electronic components, it is used for precision grinding and polishing of wafers and chips to improve the performance and reliability of products.

3.Optical instruments: It is suitable for grinding and polishing optical glass, lenses, etc., to improve the accuracy and transparency of optical components.

4.Other fields: It can also be used in the processing of steel laser cut parts debunring, plastic stamping parts deburring, 3D print parts polishing and etc.

|

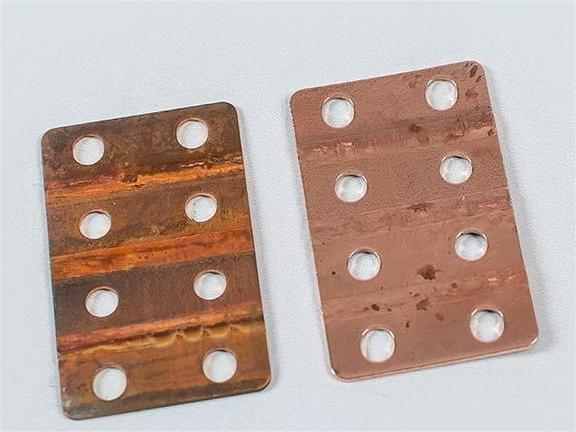

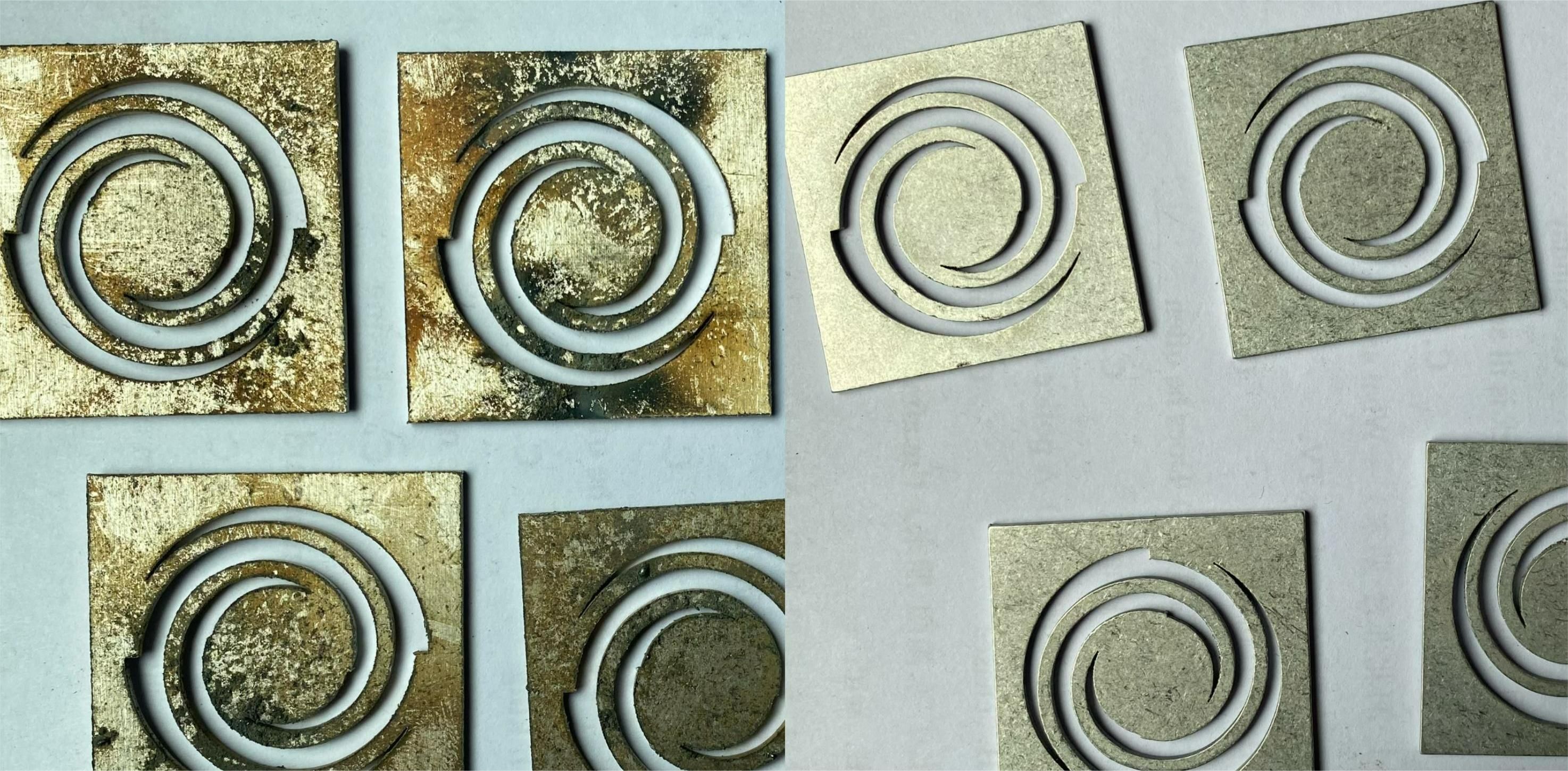

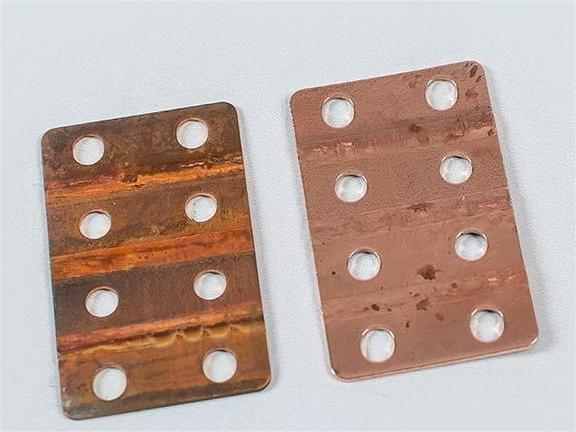

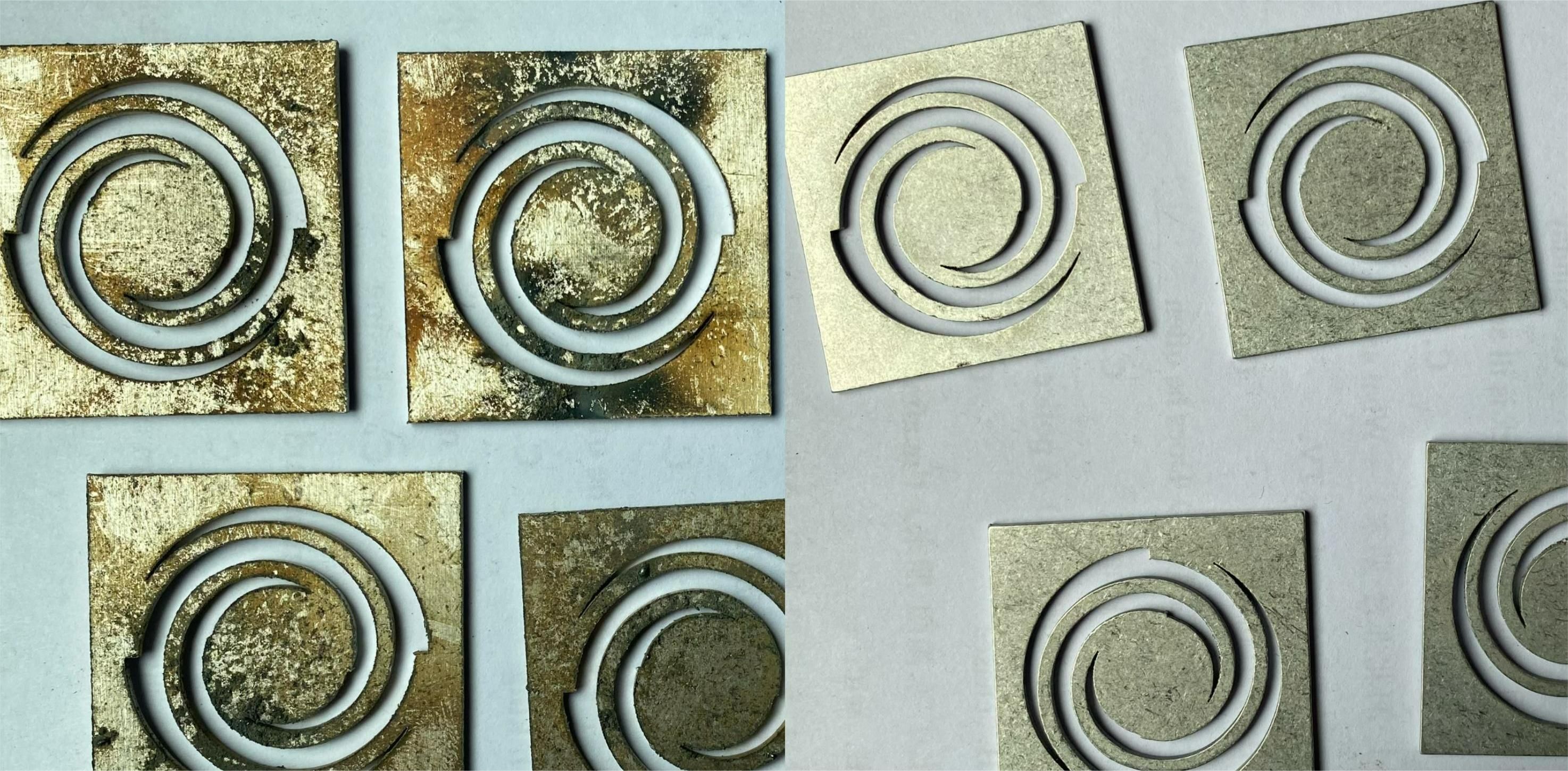

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general ceramic media parameter information we can provide. There are different shapes: ball, cylinder, angle cut cylinder, triangle, angle cut triangle, tri-star, grain etc.The different sizes can increase or decrease its polishing ability. Besides, we can produce and supply polishing media of special and specifications designed according to your demands. We will try our best to help you solve your polishing problems.

|

Product Factory Real Show

|

Company Profile

Huzhou Nanxun Shengxiang Polishing Machinery Factory has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect polishing solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

|

Product Description

Norden machinery is one of the companies with a wide range of tumbling polishing medias and brighteners in the global market. After more than 20 years of continuous exploration and improvement, we now have grinding media including: plastic media, ceramic media, brown corundum, stainless steel media and various brighteners. According to the various needs of different customers around the world, we are constantly developing new tumbling media to meet customer needs and constantly solving various surface polishing and deburring treatment problems.

Ceramic media is a new kind of grinding material, which has many excellent properties and is widely used in grinding, polishing and other fields. It is mainly based on alumina and other ceramic materials, and is prepared by special process treatment and adding some auxiliary ingredients (such as additives, crystal seeds, etc.). These additives can improve the performance of abrasives, such as increasing hardness, self-sharpness and so on.

We have two main types of ceramic porcelain polishing media: the standard porcelain tumbling media with alumina content of 30-40% and the fine porcelain tumbling media with alumina content of 70%. Porcelain tumbling media is sturdy and robust media. It can be used either in an industrial vibratory tumbler bowl or high energy centrifugal disc finishing machine.

Triangle(SCT)

Ball

Cylinder(ACC)

Triangle(ACT)

|

Feature

1. The hardness of ceramic media is usually high. It has no fragmentation and low wear during use. And it has excellent cutting performance. The surface is not blocked, and the polishing ability is strong. It can effectively grind a variety of materials.

2. Compared with traditional polishing abrasives, ceramic abrasives have better toughness. It is not easy to break during grinding and deburring process and can maintain better grinding shape and dimensional accuracy.

3. In the grinding process, the surface of the ceramic abrasive will constantly form a new sharp cutting edge to maintain a good polishing performance. So it helps to reduce the need for frequent replacement due to ceramic media blunting and improves the service life of the ceramic polishing media.

4. Ceramic abrasive can maintain good performance in high temperature environment. It is not easy to change performance or damage due to high temperature. So it is suitable for high-speed grinding and high temperature processing and other occasions.

| Application

Ceramic media has a wide application in various industries.

1.Machining process: It is suitable for deburring, grinding and polishing of metal materials, such as parts processing in automotive, aerospace, machinery manufacturing and other industries.

2.Electronics industry: In the manufacturing process of semiconductors and electronic components, it is used for precision grinding and polishing of wafers and chips to improve the performance and reliability of products.

3.Optical instruments: It is suitable for grinding and polishing optical glass, lenses, etc., to improve the accuracy and transparency of optical components.

4.Other fields: It can also be used in the processing of steel laser cut parts debunring, plastic stamping parts deburring, 3D print parts polishing and etc.

|

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general ceramic media parameter information we can provide. There are different shapes: ball, cylinder, angle cut cylinder, triangle, angle cut triangle, tri-star, grain etc.The different sizes can increase or decrease its polishing ability. Besides, we can produce and supply polishing media of special and specifications designed according to your demands. We will try our best to help you solve your polishing problems.

|

Product Factory Real Show

|

Company Profile

Huzhou Nanxun Shengxiang Polishing Machinery Factory has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect polishing solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging