- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ND-01

Norden

|

Product Description

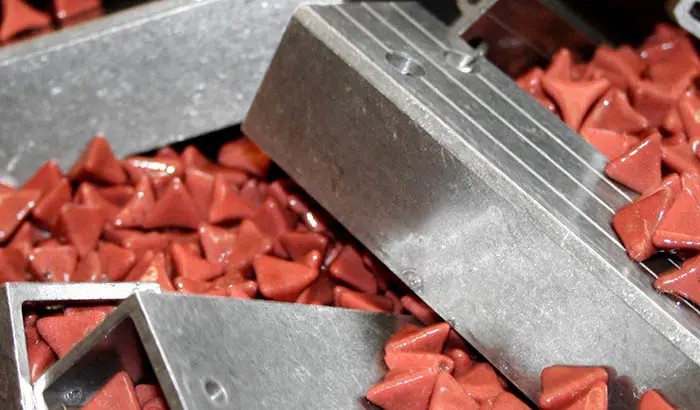

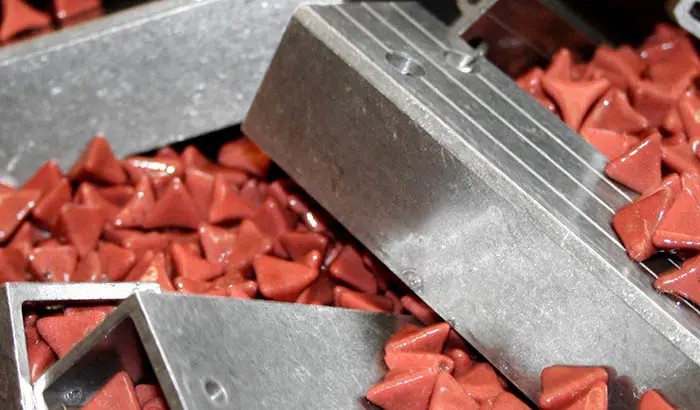

Plastic media is used for surface polishing treatment. Through the vibration, centrifugal movement, eddy current rotation, drum rotation and other ways of grinding machine, so as to drive the polishing media and products tumbling together. Finally, it help you to achieving removing burr, flash, oxide layer and rust spots on the surface of the products.

Plastic tumbling polishing medias are mainly composed of resin, abrasive particle and additives. The resin acts as a binder to hold the abrasive particles together. Commonly used resins are phenolic resin, epoxy resin, polyester resin and so on. Common abrasive particles are alumina, silicon carbide, diamond and so on. The abrasive particle size is larger and the content is higher, the deburring force is greater. Additives are used to improve the performance of resin abrasives, such as increasing hardness and improving wear resistance and cutting performance. However, it should be noted that the cutting efficiency is higher, the wear resistance of the abrasive is lower and the wear rate is higher.

The service life of plastic abrasives depends on different application and there is no standard wear time. If you find that the grinding time increases, the polishing effect is not good, or when the polishing machine hole is stuck or the joint is blocked, you must replace the new abrasive or reconsider the polishing plan.

At present, we still keep manual injection molding, stripping, screening and packaging. The plastic media shape is more complex and abrasive and the size is smaller, the more manpower is needed and the loss of raw materials is greater. So the overall cost is also higher. Manpower, mold, raw materials, transportation are the four important elements of plastic abrasive pricing. Therefore, Nordern machinery factory not only produces and sells abrasives, but also supplies grinding machines, grinding additives (brightener/grinding fluid/cleaning agent) and other products. Our plastic polishing abrasives supply chain is well established.

|

Feature

1.Good flexibility: In the polishing process, it can adapt to the irregular shape of the product surface to a certain extent. For example, when polishing metal products with complex surfaces, plastic polishing abrasives can better fit the surface and avoid scratches or damage. This flexibility also reduces vibration and noise during the polishing process to make the working environment more comfortable.

2.Good self-sharpness: It will gradually wear out during the polishing process. Due to the resin binder, when the outer abrasive particles are worn, the new abrasive particles in the inner layer can be exposed in time to maintain better polishing efficiency and quality.

3.High polishing accuracy: By screening abrasives of different sizes, you can achieve different polishing stages from rough polishing to fine polishing. For example, in the polishing process of optical lenses, the coarse resin polishing abrasives are first used to remove most of the defects and processing marks on the surface. And then the fine-grained abrasives are used to fine polish to make the surface of the lens reach a very high flatness and finish.

|

Application Video

Plastic medias are widely used in surface treatment of various parts because of their elastomer properties.

1.Metal industry: It is widely used in the surface treatment of metal products. For example, in the production process of stainless steel tableware, the plastic polishing abrasive is used to remove the burrs and scratches. For precision metal parts, such as metal parts in the aerospace field, the plastic polishing abrasive can achieve high precision polishing, and thus improve the corrosion resistance of parts.

2.Optical industry: It is the key abrasive for polishing optical components such as optical lenses and prisms. Taking the camera lens as an example, plastic polishing abrasives can control the accuracy of the lens surface at the micron level through the fine polishing process to ensure the high light transmittance and imaging quality of the lens. In the production of optical instruments such as microscopes and telescopes, plastic polishing abrasives also play an irreplaceable role in ensuring that optical components can accurately refract.

3.Stone processing field: It is used for the surface polishing of marble, granite and other stone. In the production process of stone panels, resin polishing abrasives can make the texture of the stone surface more clearly and improve the surface gloss. In the post-processing of stone carvings, it can finely polish the carved surface and enhance the artistic beauty of the carvings.

4.Electronics industry: The plastic polishing abrasive can polish the surface of the circuit board to remove the oxide layer and impurities on the surface and improve the electrical conductivity and weld ability of the circuit board. For some high-precision electronic chip packaging shells, it can also be used to polish them to meet the appearance and performance requirements.

In short, plastic tumbling polishing medias are an important abrasive material and have a wide range of application prospects. It is necessary to choose the appropriate plastic abrasives according to different processing needs.

|

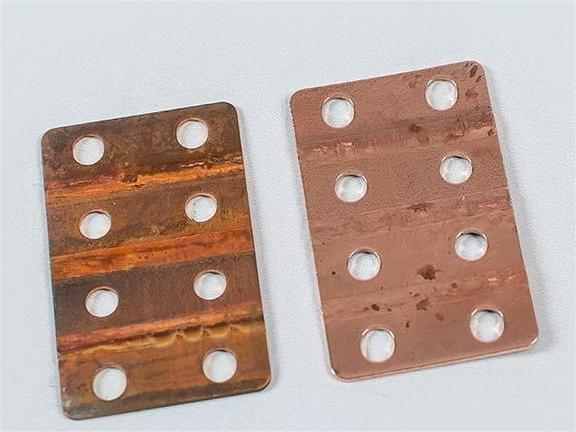

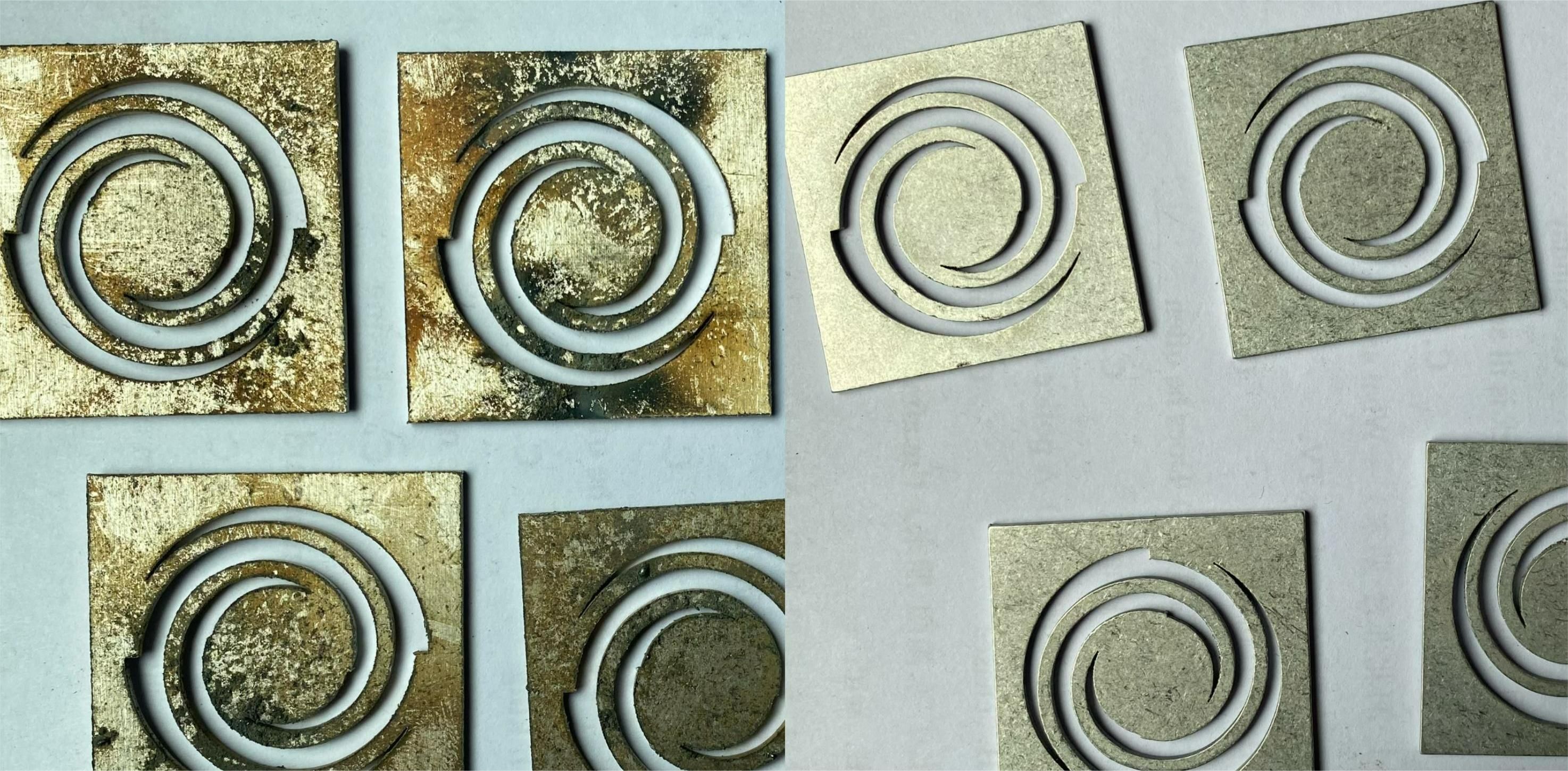

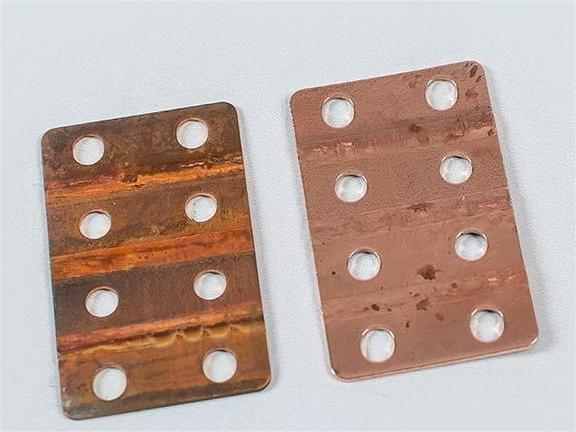

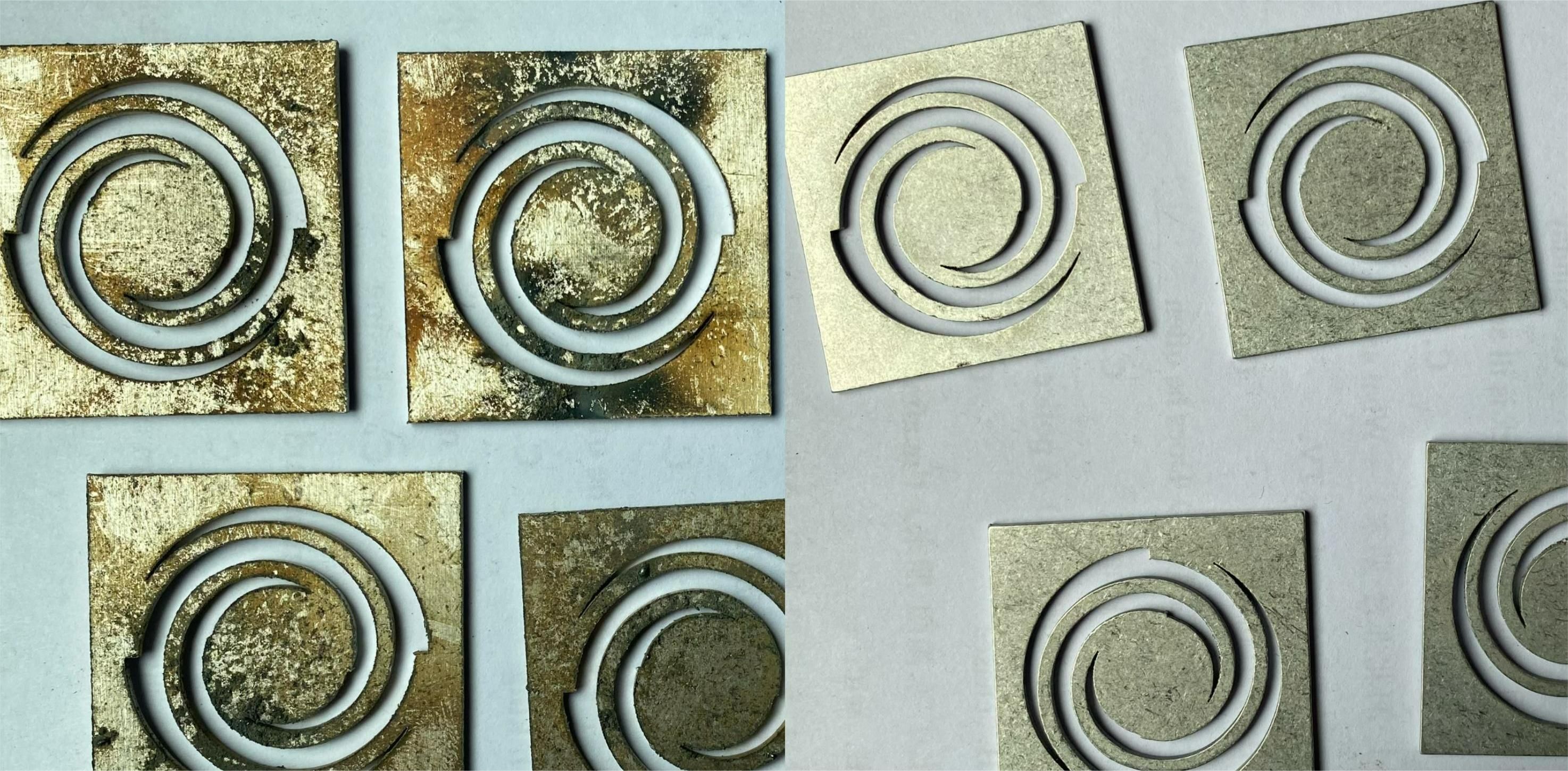

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Plastic medias are mainly conical shape, triangular pyramid, quadrangular shape, bullet shape and other standard shapes. It can be made into different specifications, such as different diameters, thicknesses, etc., to adapt to different sizes of products and polishing machines. You can also customize other shapes according to the shape of the part.

The shape and size of the plastic polishing media will affect the grinding result. Small size medias have small contact surface with products and the polished surface will be smoother and more delicate. The large size medias have stronger cutting ability. Conical and pyramidal shapes are the most common. This kind of abrasives top is small and the bottom is large, so it generally does not stick into the slots and holes of the polishing machine. For the full symmetric type of abrasive, if you choose the wrong size, there is a risk of sticking. Triangular cone abrasives are most suitable for grinding special-shaped parts with complex structures due to its sharp corners and edges which can reach smaller gaps and holes. You can also choose to mix different shapes and sizes of plastic polishing media together.

|

Company Profile

Norden machinery is one of the companies with a wide range of tumbling polishing medias and brighteners in the global market. After more than 20 years of continuous exploration and improvement, we now have grinding media including: plastic media, ceramic media, brown corundum, stainless steel media and various brighteners. According to the various needs of different customers around the world, we are constantly developing new tumbling media to meet customer needs and constantly solving various surface polishing and deburring treatment problems.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect polishing solution!

|

Delivery

Nordern is committed to providing you with professional, reliable and efficient logistics solutions to ensure that your goods reach your destination smoothly and quickly.

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

|

Product Description

Plastic media is used for surface polishing treatment. Through the vibration, centrifugal movement, eddy current rotation, drum rotation and other ways of grinding machine, so as to drive the polishing media and products tumbling together. Finally, it help you to achieving removing burr, flash, oxide layer and rust spots on the surface of the products.

Plastic tumbling polishing medias are mainly composed of resin, abrasive particle and additives. The resin acts as a binder to hold the abrasive particles together. Commonly used resins are phenolic resin, epoxy resin, polyester resin and so on. Common abrasive particles are alumina, silicon carbide, diamond and so on. The abrasive particle size is larger and the content is higher, the deburring force is greater. Additives are used to improve the performance of resin abrasives, such as increasing hardness and improving wear resistance and cutting performance. However, it should be noted that the cutting efficiency is higher, the wear resistance of the abrasive is lower and the wear rate is higher.

The service life of plastic abrasives depends on different application and there is no standard wear time. If you find that the grinding time increases, the polishing effect is not good, or when the polishing machine hole is stuck or the joint is blocked, you must replace the new abrasive or reconsider the polishing plan.

At present, we still keep manual injection molding, stripping, screening and packaging. The plastic media shape is more complex and abrasive and the size is smaller, the more manpower is needed and the loss of raw materials is greater. So the overall cost is also higher. Manpower, mold, raw materials, transportation are the four important elements of plastic abrasive pricing. Therefore, Nordern machinery factory not only produces and sells abrasives, but also supplies grinding machines, grinding additives (brightener/grinding fluid/cleaning agent) and other products. Our plastic polishing abrasives supply chain is well established.

|

Feature

1.Good flexibility: In the polishing process, it can adapt to the irregular shape of the product surface to a certain extent. For example, when polishing metal products with complex surfaces, plastic polishing abrasives can better fit the surface and avoid scratches or damage. This flexibility also reduces vibration and noise during the polishing process to make the working environment more comfortable.

2.Good self-sharpness: It will gradually wear out during the polishing process. Due to the resin binder, when the outer abrasive particles are worn, the new abrasive particles in the inner layer can be exposed in time to maintain better polishing efficiency and quality.

3.High polishing accuracy: By screening abrasives of different sizes, you can achieve different polishing stages from rough polishing to fine polishing. For example, in the polishing process of optical lenses, the coarse resin polishing abrasives are first used to remove most of the defects and processing marks on the surface. And then the fine-grained abrasives are used to fine polish to make the surface of the lens reach a very high flatness and finish.

|

Application Video

Plastic medias are widely used in surface treatment of various parts because of their elastomer properties.

1.Metal industry: It is widely used in the surface treatment of metal products. For example, in the production process of stainless steel tableware, the plastic polishing abrasive is used to remove the burrs and scratches. For precision metal parts, such as metal parts in the aerospace field, the plastic polishing abrasive can achieve high precision polishing, and thus improve the corrosion resistance of parts.

2.Optical industry: It is the key abrasive for polishing optical components such as optical lenses and prisms. Taking the camera lens as an example, plastic polishing abrasives can control the accuracy of the lens surface at the micron level through the fine polishing process to ensure the high light transmittance and imaging quality of the lens. In the production of optical instruments such as microscopes and telescopes, plastic polishing abrasives also play an irreplaceable role in ensuring that optical components can accurately refract.

3.Stone processing field: It is used for the surface polishing of marble, granite and other stone. In the production process of stone panels, resin polishing abrasives can make the texture of the stone surface more clearly and improve the surface gloss. In the post-processing of stone carvings, it can finely polish the carved surface and enhance the artistic beauty of the carvings.

4.Electronics industry: The plastic polishing abrasive can polish the surface of the circuit board to remove the oxide layer and impurities on the surface and improve the electrical conductivity and weld ability of the circuit board. For some high-precision electronic chip packaging shells, it can also be used to polish them to meet the appearance and performance requirements.

In short, plastic tumbling polishing medias are an important abrasive material and have a wide range of application prospects. It is necessary to choose the appropriate plastic abrasives according to different processing needs.

|

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Plastic medias are mainly conical shape, triangular pyramid, quadrangular shape, bullet shape and other standard shapes. It can be made into different specifications, such as different diameters, thicknesses, etc., to adapt to different sizes of products and polishing machines. You can also customize other shapes according to the shape of the part.

The shape and size of the plastic polishing media will affect the grinding result. Small size medias have small contact surface with products and the polished surface will be smoother and more delicate. The large size medias have stronger cutting ability. Conical and pyramidal shapes are the most common. This kind of abrasives top is small and the bottom is large, so it generally does not stick into the slots and holes of the polishing machine. For the full symmetric type of abrasive, if you choose the wrong size, there is a risk of sticking. Triangular cone abrasives are most suitable for grinding special-shaped parts with complex structures due to its sharp corners and edges which can reach smaller gaps and holes. You can also choose to mix different shapes and sizes of plastic polishing media together.

|

Company Profile

Norden machinery is one of the companies with a wide range of tumbling polishing medias and brighteners in the global market. After more than 20 years of continuous exploration and improvement, we now have grinding media including: plastic media, ceramic media, brown corundum, stainless steel media and various brighteners. According to the various needs of different customers around the world, we are constantly developing new tumbling media to meet customer needs and constantly solving various surface polishing and deburring treatment problems.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect polishing solution!

|

Delivery

Nordern is committed to providing you with professional, reliable and efficient logistics solutions to ensure that your goods reach your destination smoothly and quickly.

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging