- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

36L

Norden

|

Product Description

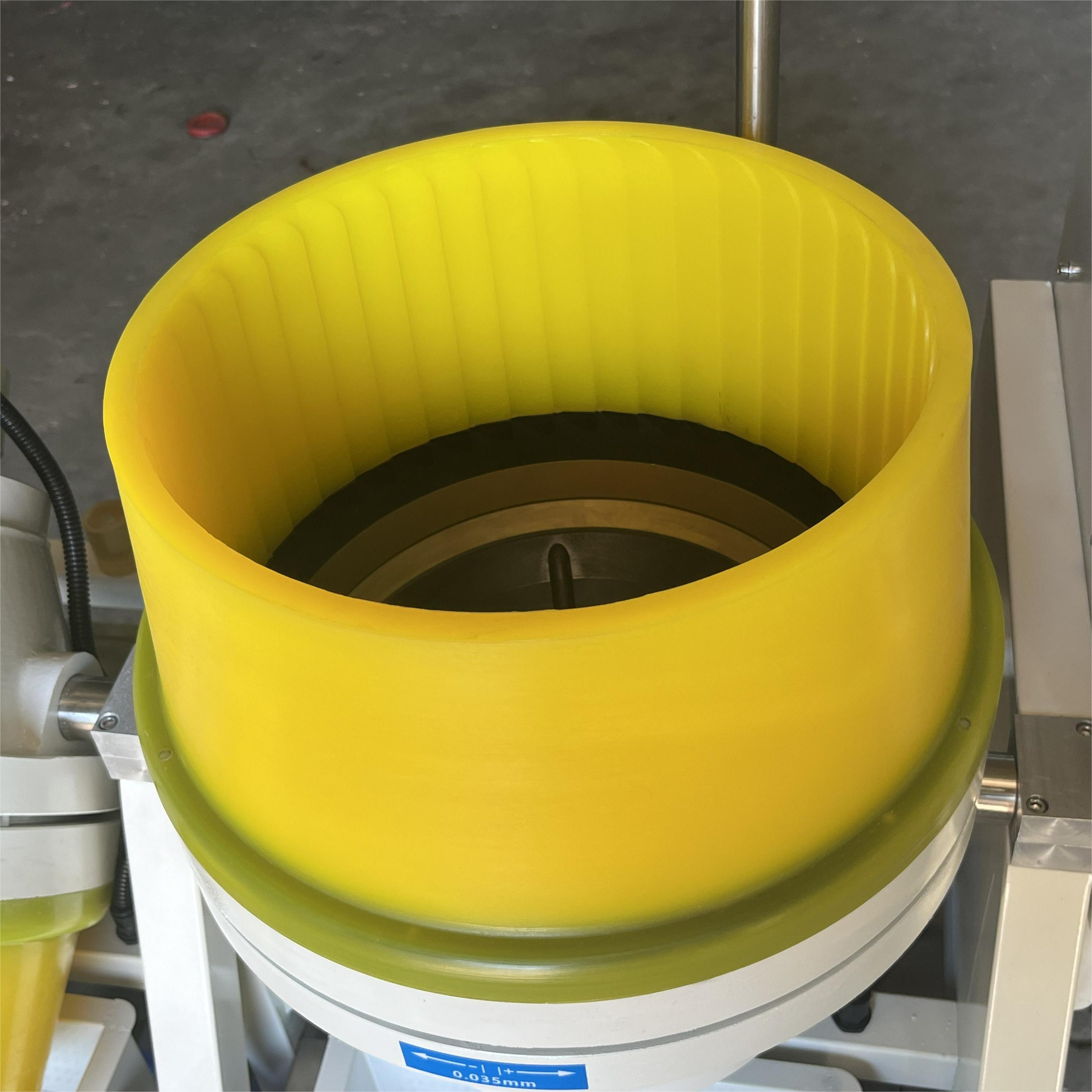

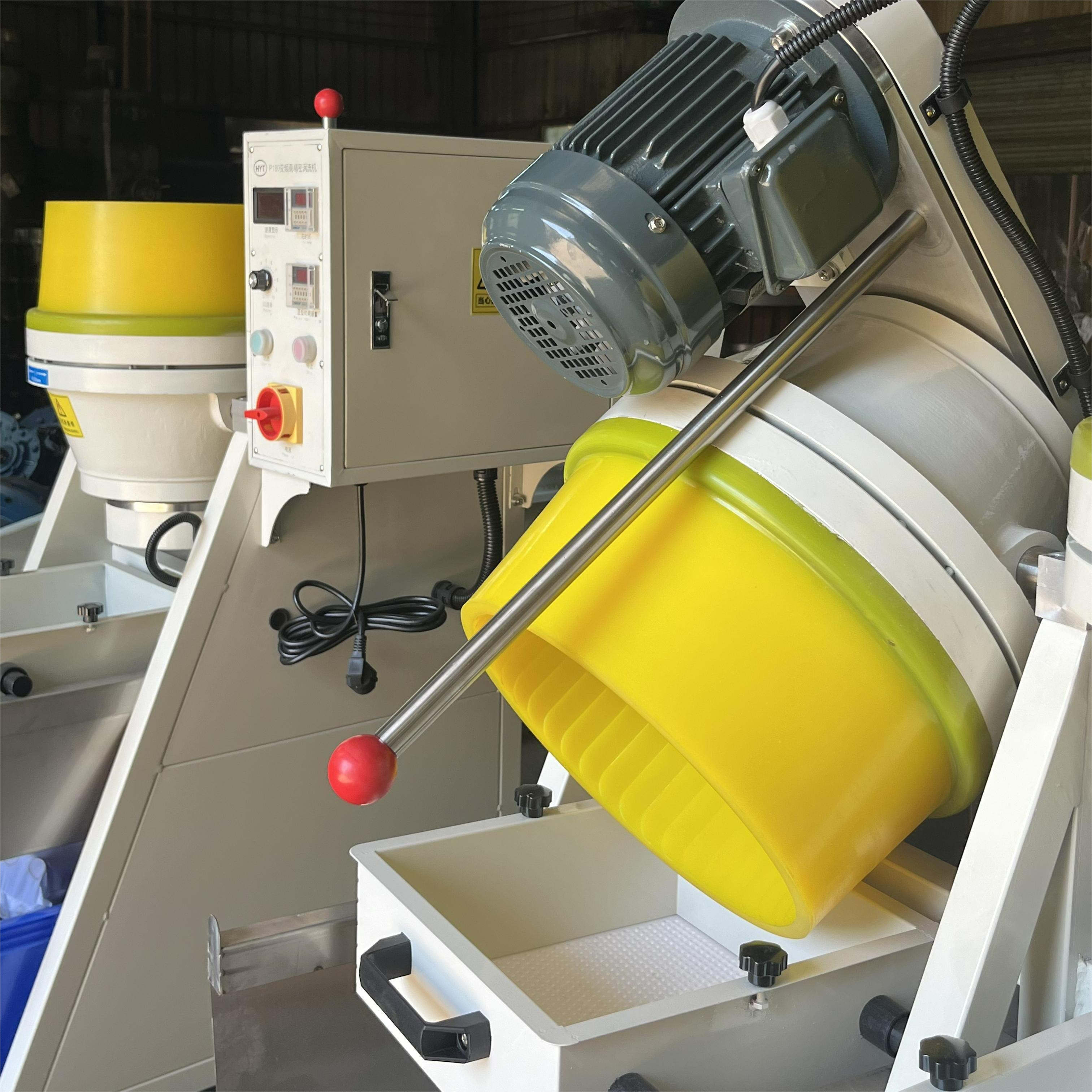

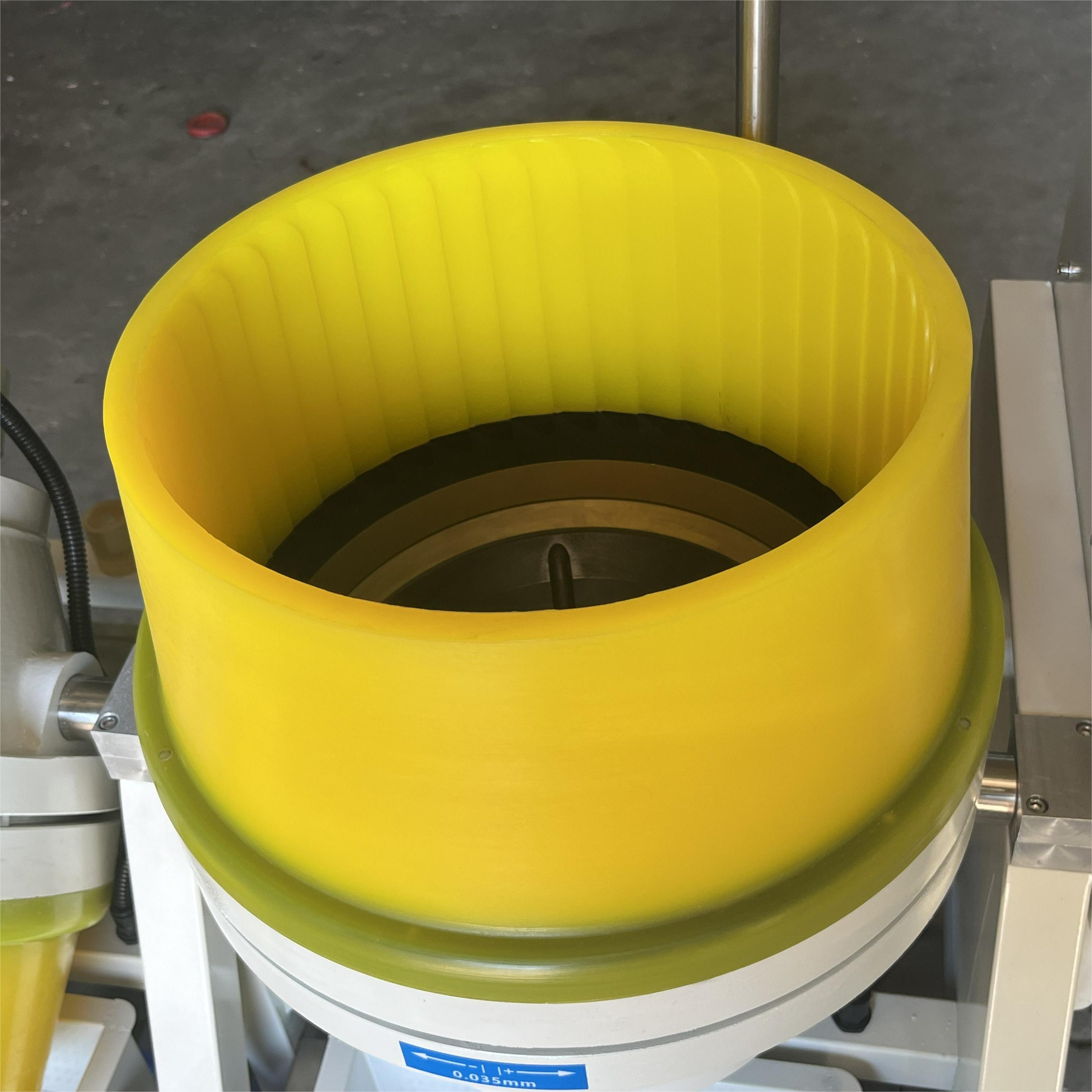

Jewelry polishing machine adopts the principle of eddy current flow and polishes the products through high speed rotation. When the rotating disc begins to rotate, the tumbling polishing abrasives and the products in the grinding disc move upward along the wall of the cylinder by centrifugal force. Then relying on the weight of the products and abrasives, they fall from the height of the grinding disc back to the middle of the rotating disc. This repetition causes the products and abrasives to move continuously in a spiral shape, resulting in a highly efficient grinding. Therefore, the jewelry polishing machine can polish products with high precision mirror, achieve superior efficiency and increase the work efficiency by 15-30 times.

SINGLE BUCKET

SINGLE BUCKET

DOUBLE BUCKET

DOUBLE BUCKET

Norden machinery has a professional technical team and rich manufacturing experience in jewelry and gemstone polishing. Our jewelry polishing machine not only have excellent performance, but also have deep care for users. We hope that our polishing machines can help you in your business.

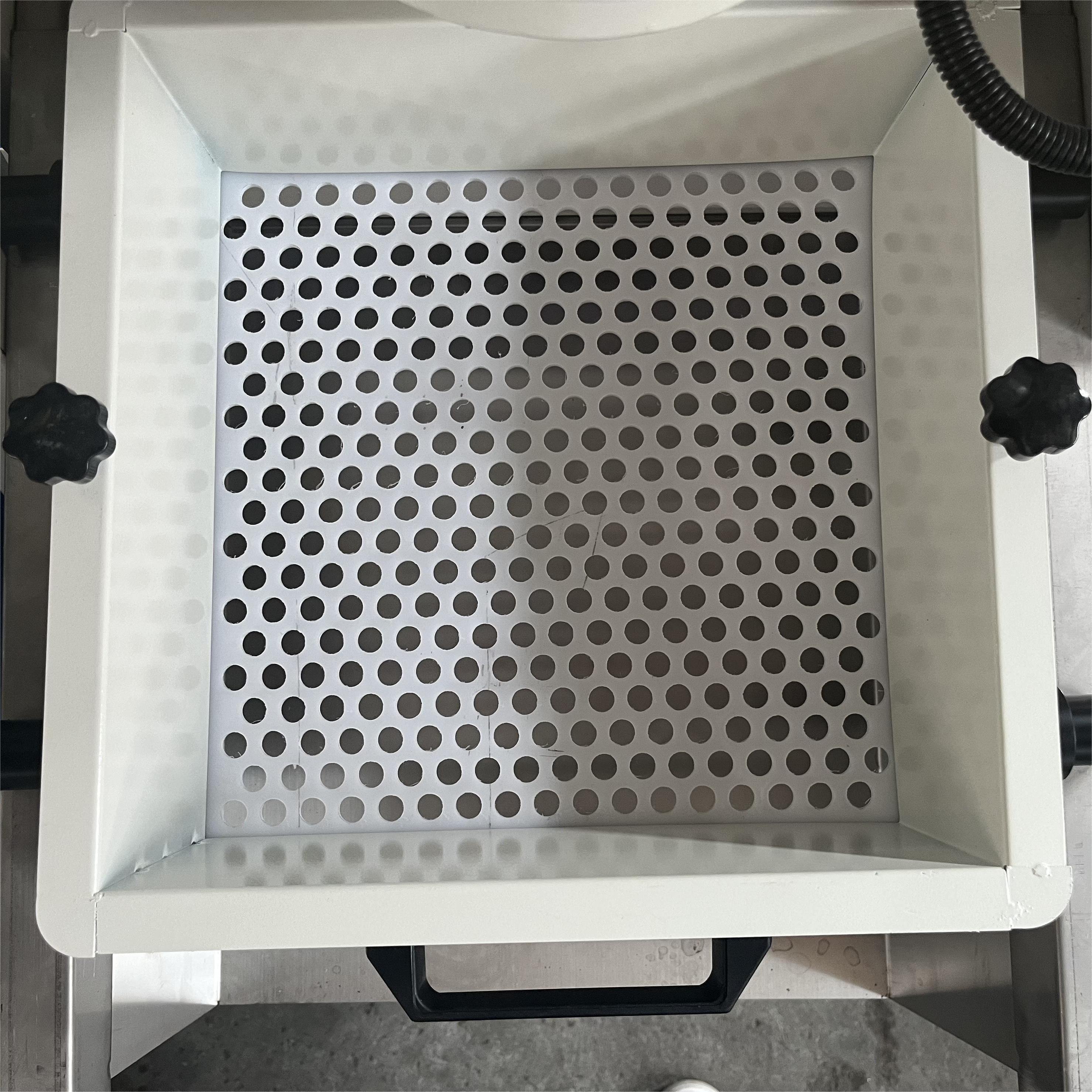

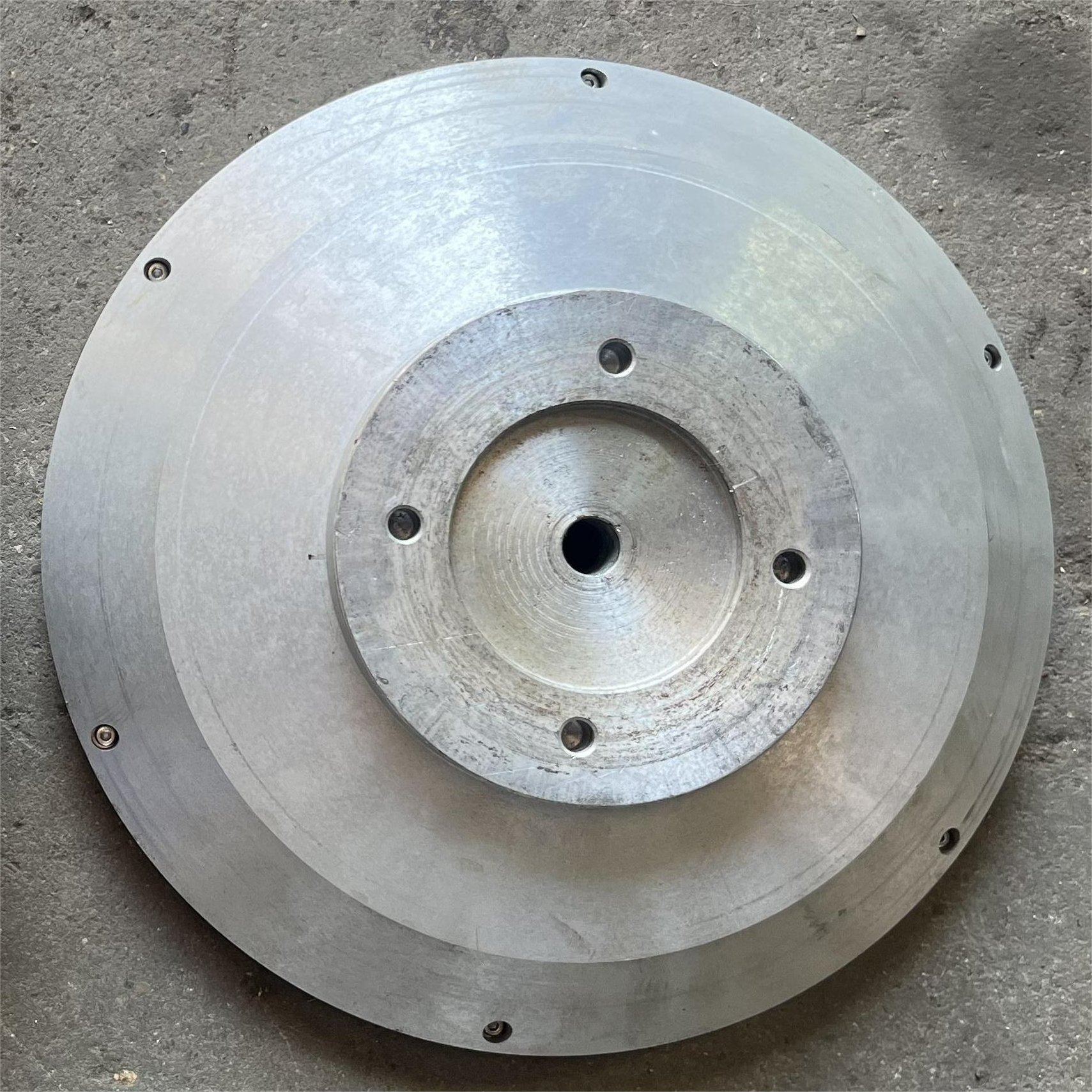

1. The polishing barrel body and the inner lining of the rotary disc are made of high wear-resistant PU material. This material is waterproof and resistant to acid and alkali. It is also wear-resistant to impact and has a long service life.

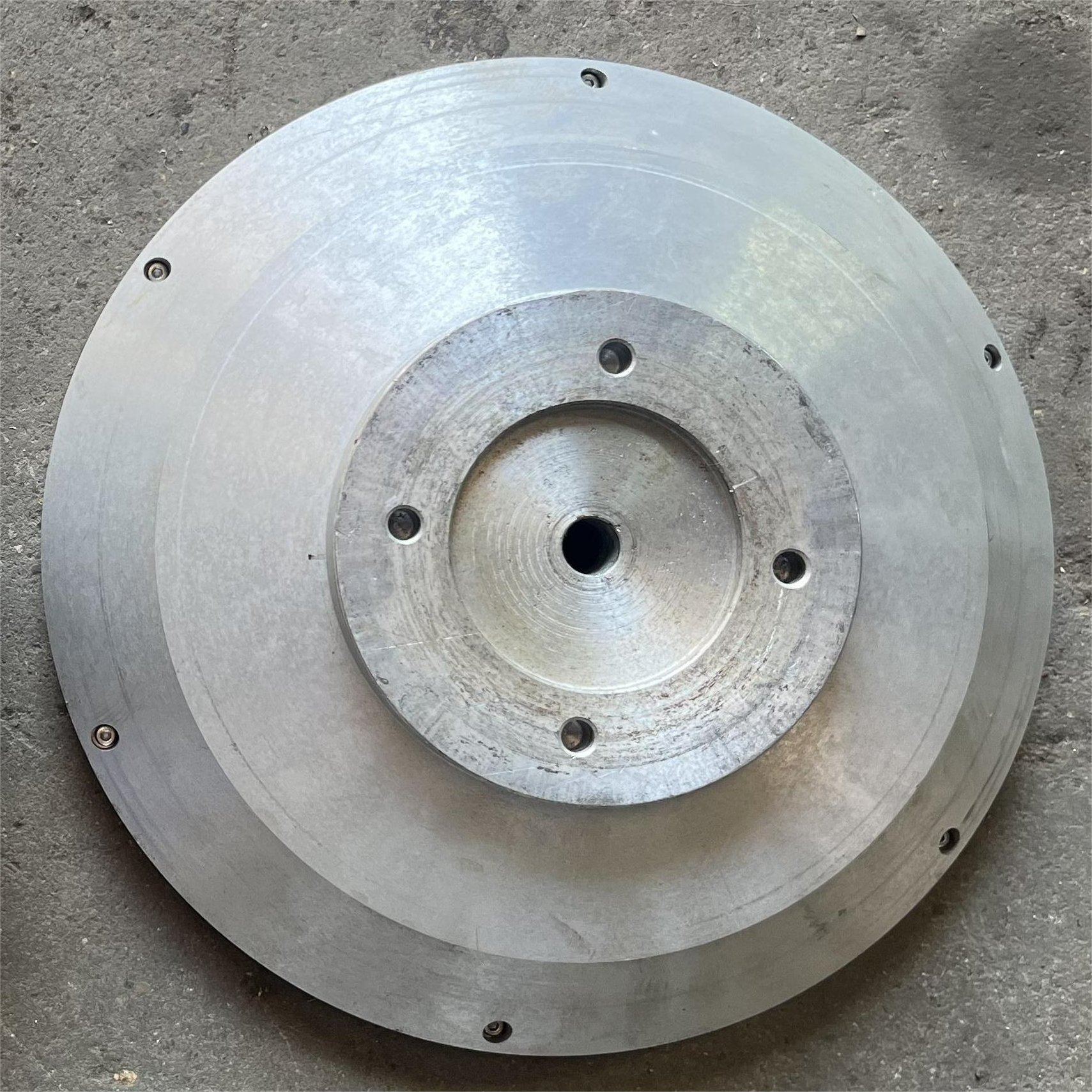

2. The rotating chassis speed can be selected according to the polishing needs. The speed can be adjusted between 0-250 r/min.

3. The fixed groove and the turntable are lined with polyurethane rubber, which has high strength, good wear resistance and long service life.

4. The inner copper motor has strong vibration performance and efficient durable.

5. The products polishing processing condition can be checked at any time, thus reducing the grinding operation time.

6. Unloading is done by turning the polishing barrel handle.

|

Feature

1. Achieving deburring, polishing and plastic products chamfer.

2. Timing polishing processing, the operation is simple and without any security risks.

3. Dry polishing processing can meet the product mirror brightness requirements.

4. Efficient polishing processing can meet customer demand for high speed.

5. The process does not need manual intervention, one person can operate multiple machines.

6. Using the high wear-resistant tungsten alloy washer structure.

7. Voltage, current, frequency, time are digital monitoring.

8. Compact design for both wet and dry grinding.

9. Using the ultra-thick and wear-resistant PU material.

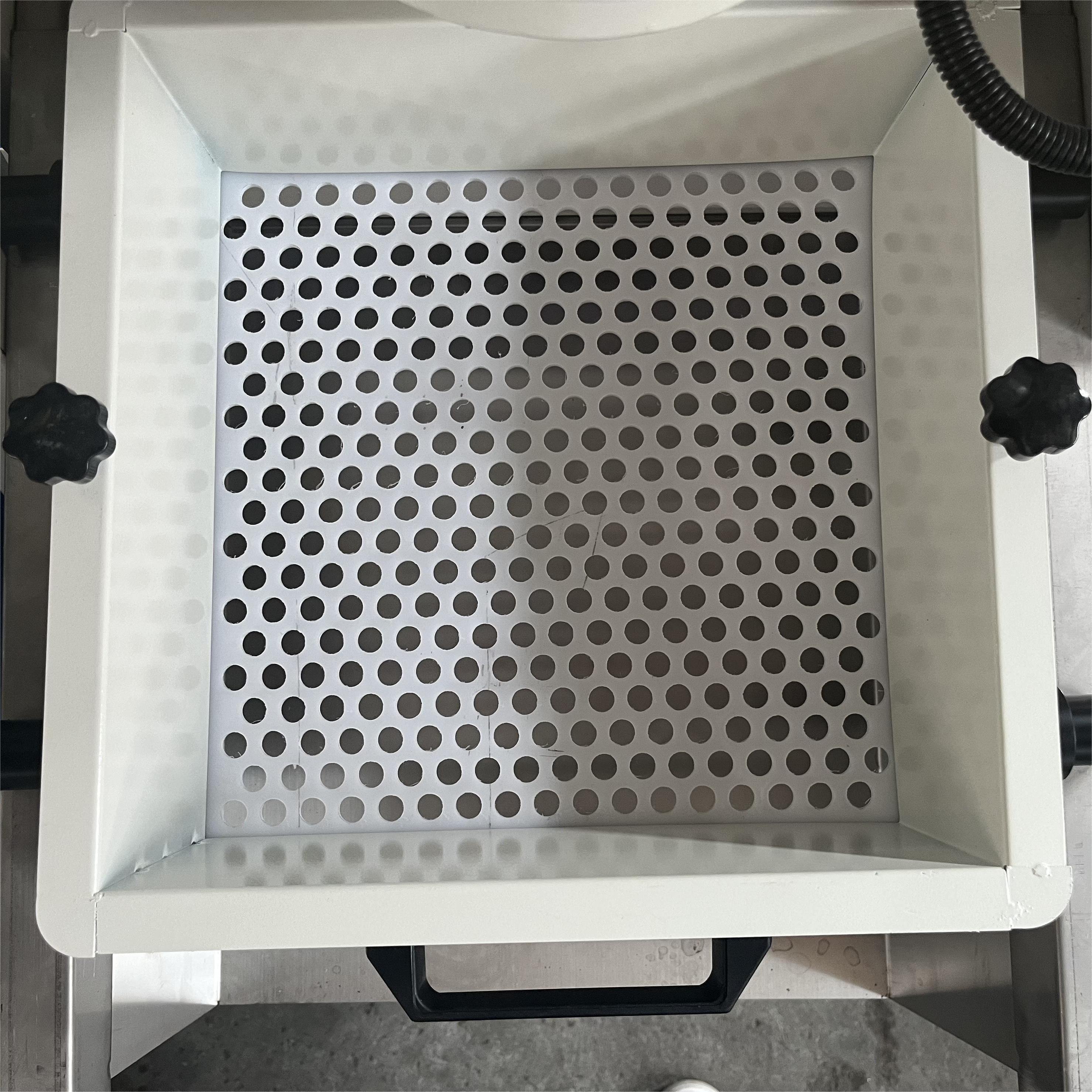

10. Automatic circulating water treatment system.

|

Application

Jewelry polishing machine is suitable for the surface grinding and polishing of small and medium-sized parts in batches, especially to solve the difficult problems of grinding such as overlapping and embedding deformation of thin and filamentous parts. At the same time, you may also use some suitable tumbling polishing abrasives to help you get the best polishing effect. Here are some products are suited to the jewelry polishing machine.

1. Coins: silver coin, bronze coin, nickel coin, aluminum coin, brass coin, gold coin.

2. Pendants: gold pendants, silver pendants, amber pendants.

3. Earrings: gold earrings, silver earrings, amber earrings, aluminum earrings.

4. Necklaces: gold necklace, silver necklace, amber necklace, aluminum necklace.

5. Rings: steel ring, silver ring, iron ring, gold ring, aluminum ring, brass ring.

6. Chains: gold chains, silver chains, amber chains.

7. Bracelets: gold bracelets, silver bracelets, amber bracelets.

8. Pearls: freshwater pearls, yellow south sea cultured pearls,saltwater sea pearls.

9. Watch case: stainless steel watch case, titanium watch case, bronze watch case, ceramic watch case, machines watch case, 3d printed watch case.

10. ...

Bracelets

Bracelets

Pendants

Earrings

Necklaces

Rings

Chains

Coins

Pearls

Watch case

|

Size Information

Here is the general jewelry polishing machine parameter information. We truly hope that our jewelry polishing machine can help you in your business.

We can provide you with product customization services. We will try our best to make the color or special shape you prefer. If you have any special customization needs, please contact us.

| MODLE | Volume (L) | Power (KW) | Voltage (V) | Maximum Speed (r/min) | Outer Diameter (CM) | Weight (KG) |

| 18L SINGLE BUCKET | 18 | 0.75 | 220 | 500 | 70*90*140 | 140 |

| 18L DOUBLE BUCKET | 18X2 | 0.75X2 | 220 | 500 | 120*90*140 | 235 |

| 36L SINGLE BUCKET | 36 | 2.2 | 380 | 500 | 95*90*145 | 220 |

| 36L DOUBLE BUCKET | 36X2 | 2.2X2 | 380 | 500 | 150*90*145 | 370 |

18L SINGLE BUCKET

18L DOUBLE BUCKET

36L SINGLE BUCKET

36L DOUBLE BUCKE

|

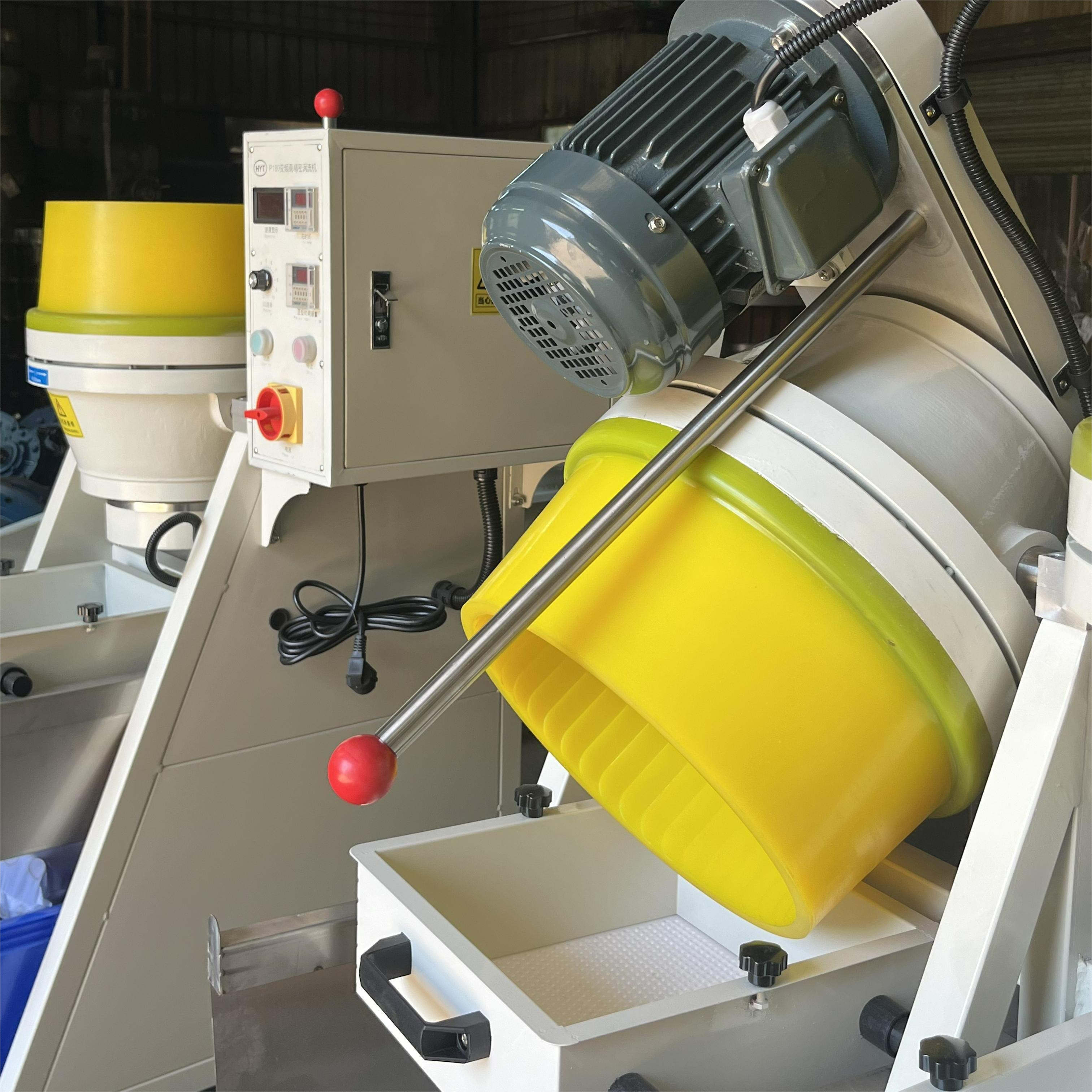

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Jewelry polishing machine adopts the principle of eddy current flow and polishes the products through high speed rotation. When the rotating disc begins to rotate, the tumbling polishing abrasives and the products in the grinding disc move upward along the wall of the cylinder by centrifugal force. Then relying on the weight of the products and abrasives, they fall from the height of the grinding disc back to the middle of the rotating disc. This repetition causes the products and abrasives to move continuously in a spiral shape, resulting in a highly efficient grinding. Therefore, the jewelry polishing machine can polish products with high precision mirror, achieve superior efficiency and increase the work efficiency by 15-30 times.

SINGLE BUCKET

SINGLE BUCKET

DOUBLE BUCKET

DOUBLE BUCKET

Norden machinery has a professional technical team and rich manufacturing experience in jewelry and gemstone polishing. Our jewelry polishing machine not only have excellent performance, but also have deep care for users. We hope that our polishing machines can help you in your business.

1. The polishing barrel body and the inner lining of the rotary disc are made of high wear-resistant PU material. This material is waterproof and resistant to acid and alkali. It is also wear-resistant to impact and has a long service life.

2. The rotating chassis speed can be selected according to the polishing needs. The speed can be adjusted between 0-250 r/min.

3. The fixed groove and the turntable are lined with polyurethane rubber, which has high strength, good wear resistance and long service life.

4. The inner copper motor has strong vibration performance and efficient durable.

5. The products polishing processing condition can be checked at any time, thus reducing the grinding operation time.

6. Unloading is done by turning the polishing barrel handle.

|

Feature

1. Achieving deburring, polishing and plastic products chamfer.

2. Timing polishing processing, the operation is simple and without any security risks.

3. Dry polishing processing can meet the product mirror brightness requirements.

4. Efficient polishing processing can meet customer demand for high speed.

5. The process does not need manual intervention, one person can operate multiple machines.

6. Using the high wear-resistant tungsten alloy washer structure.

7. Voltage, current, frequency, time are digital monitoring.

8. Compact design for both wet and dry grinding.

9. Using the ultra-thick and wear-resistant PU material.

10. Automatic circulating water treatment system.

|

Application

Jewelry polishing machine is suitable for the surface grinding and polishing of small and medium-sized parts in batches, especially to solve the difficult problems of grinding such as overlapping and embedding deformation of thin and filamentous parts. At the same time, you may also use some suitable tumbling polishing abrasives to help you get the best polishing effect. Here are some products are suited to the jewelry polishing machine.

1. Coins: silver coin, bronze coin, nickel coin, aluminum coin, brass coin, gold coin.

2. Pendants: gold pendants, silver pendants, amber pendants.

3. Earrings: gold earrings, silver earrings, amber earrings, aluminum earrings.

4. Necklaces: gold necklace, silver necklace, amber necklace, aluminum necklace.

5. Rings: steel ring, silver ring, iron ring, gold ring, aluminum ring, brass ring.

6. Chains: gold chains, silver chains, amber chains.

7. Bracelets: gold bracelets, silver bracelets, amber bracelets.

8. Pearls: freshwater pearls, yellow south sea cultured pearls,saltwater sea pearls.

9. Watch case: stainless steel watch case, titanium watch case, bronze watch case, ceramic watch case, machines watch case, 3d printed watch case.

10. ...

Bracelets

Bracelets

Pendants

Earrings

Necklaces

Rings

Chains

Coins

Pearls

Watch case

|

Size Information

Here is the general jewelry polishing machine parameter information. We truly hope that our jewelry polishing machine can help you in your business.

We can provide you with product customization services. We will try our best to make the color or special shape you prefer. If you have any special customization needs, please contact us.

| MODLE | Volume (L) | Power (KW) | Voltage (V) | Maximum Speed (r/min) | Outer Diameter (CM) | Weight (KG) |

| 18L SINGLE BUCKET | 18 | 0.75 | 220 | 500 | 70*90*140 | 140 |

| 18L DOUBLE BUCKET | 18X2 | 0.75X2 | 220 | 500 | 120*90*140 | 235 |

| 36L SINGLE BUCKET | 36 | 2.2 | 380 | 500 | 95*90*145 | 220 |

| 36L DOUBLE BUCKET | 36X2 | 2.2X2 | 380 | 500 | 150*90*145 | 370 |

18L SINGLE BUCKET

18L DOUBLE BUCKET

36L SINGLE BUCKET

36L DOUBLE BUCKE

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case