- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ND-01

Norden

|

Product Description

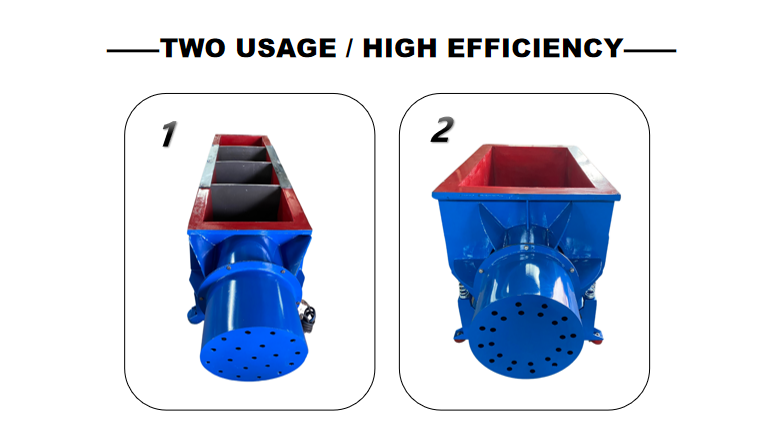

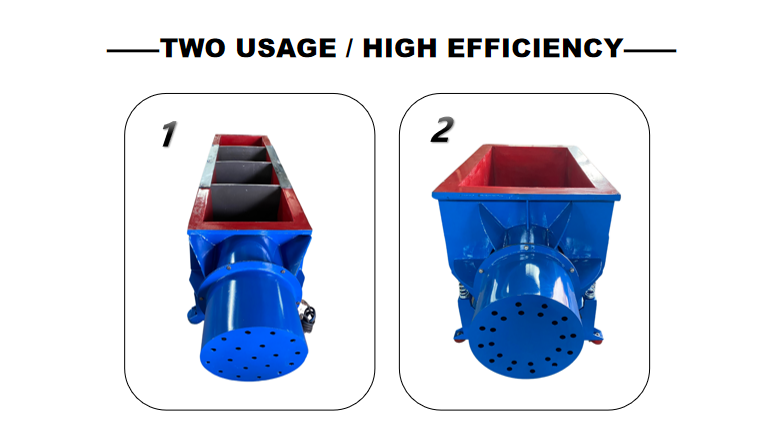

Square vibratory polishing machine is mainly composed of a vibration motor, support spring, and base. The vibration motor is fixed to the container with bolts and is placed together on the spring connected to the base. Square vibratory polishing machine is a reform and innovation on the defects of traditional polishing machines. The rolling force is transmitted to various polishing tumbling media to make the products rotate at a high frequency. It makes significantly better effect of polishing and grinding burrs the inner holes, dead corners and small cracks of precision hardware parts.

Norden machinery has been committed to producing and developing high efficiency polishing machines for more than 20 years. We have advanced technology and rich manufacturing experience. Our square vibratory polishing machine have excellent performance.

1.Square vibration polishing machine can complete all the vibration polishing machine grinding products.

For example, the antique treatment of marble slabs and the deburring treatment of metal rods. It can process multiple marble slabs and large metal rods at one time.

2.Suitable for deburring and polishing long, large products.

For pipe fittings and large products ( larger than 40CM), the square vibration polishing machine's advantage can be fully demonstrated. It uses a linear vibration movement, and the polished products are more refined and beautiful.

3.Suitable for surface finishing of complex cavity parts.

After being surface finished by this type of polishing machine, the parts not only maintain their original dimensional accuracy, but also improve the surface roughness accuracy by 1-2 grades.

Square vibratory polishing machine has removable dividers that can be placed to turn a single trough into multiple trough. Your products can be classified by placing dividers before polishing. It can be used to deal with parts that is easy to hurt each other or different types of parts. This contributes to prevent different kinds of parts from colliding with each other. Large and long products can be polished without dividers.

|

Fearures

1. With removable dividers, it can be used to handle products that are prone to scratching each other or products of different types.

2. It achieves semi-automation through an electrical control system, greatly improving work efficiency in stone polishing.

3. It has a PU lining with high wear resistance.

4. There are two motors on the shell container body, providing a smooth and even vibration force.

|

Application

Square vibratory polishing machine can be applied to the surface polishing, chamfering, deburring, polishing and brightening of small or big size parts. It does not affect the original dimensional accuracy of the product after grinding treatment. It lays a good foundation for some products subsequent electroplating, spraying and other surface treatment. Here are some parts can be polished by square vibratory polishing machine.

Connecting Rods Polishing

Valve covers polishing

Camshaft Polishing

Crankshaft Polishing

Turbo Polishing

Exhaust Pipe Polishing

Golf clubs polishing

Cutlery Polishing

Bike Frame Polishing

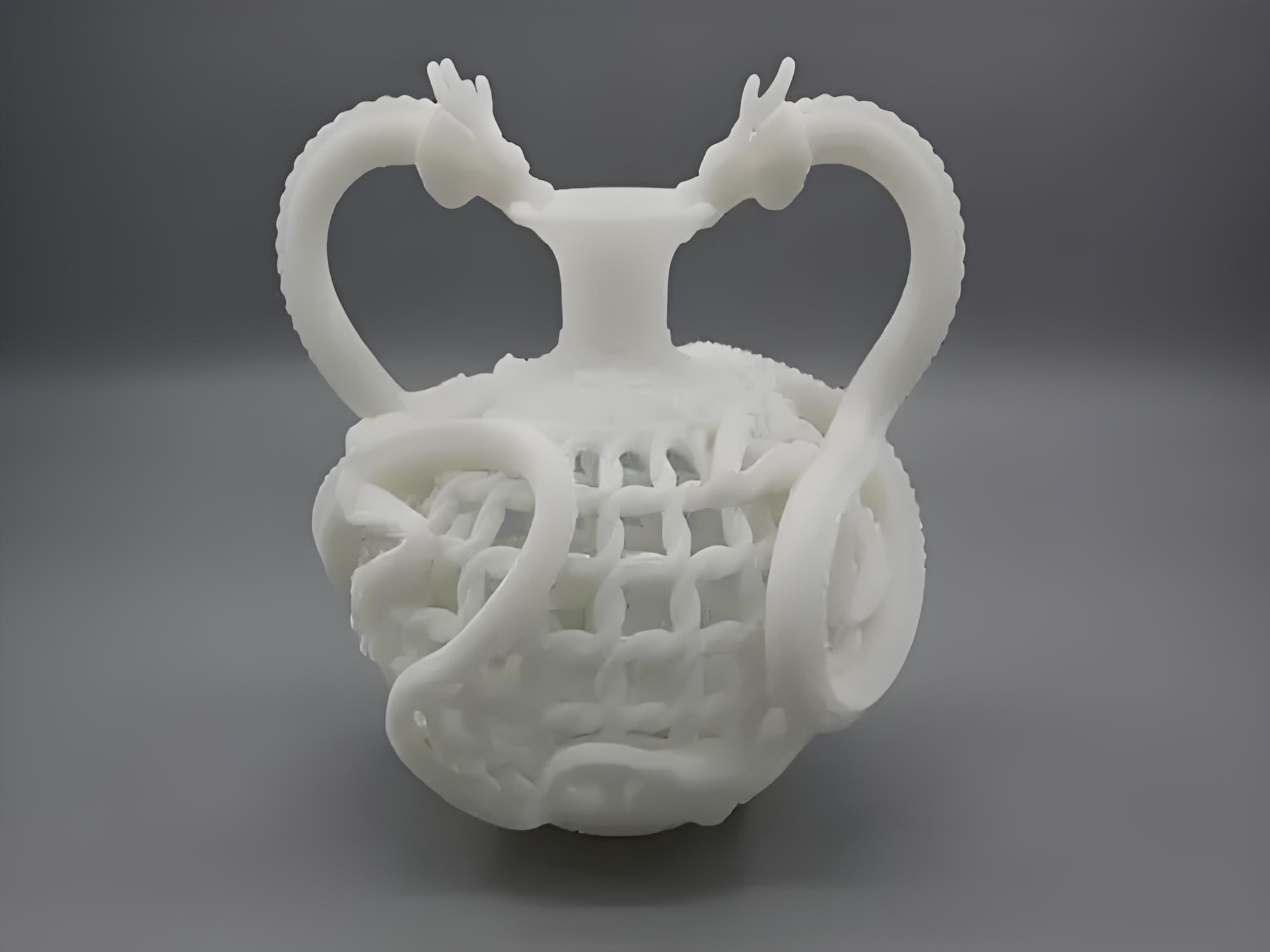

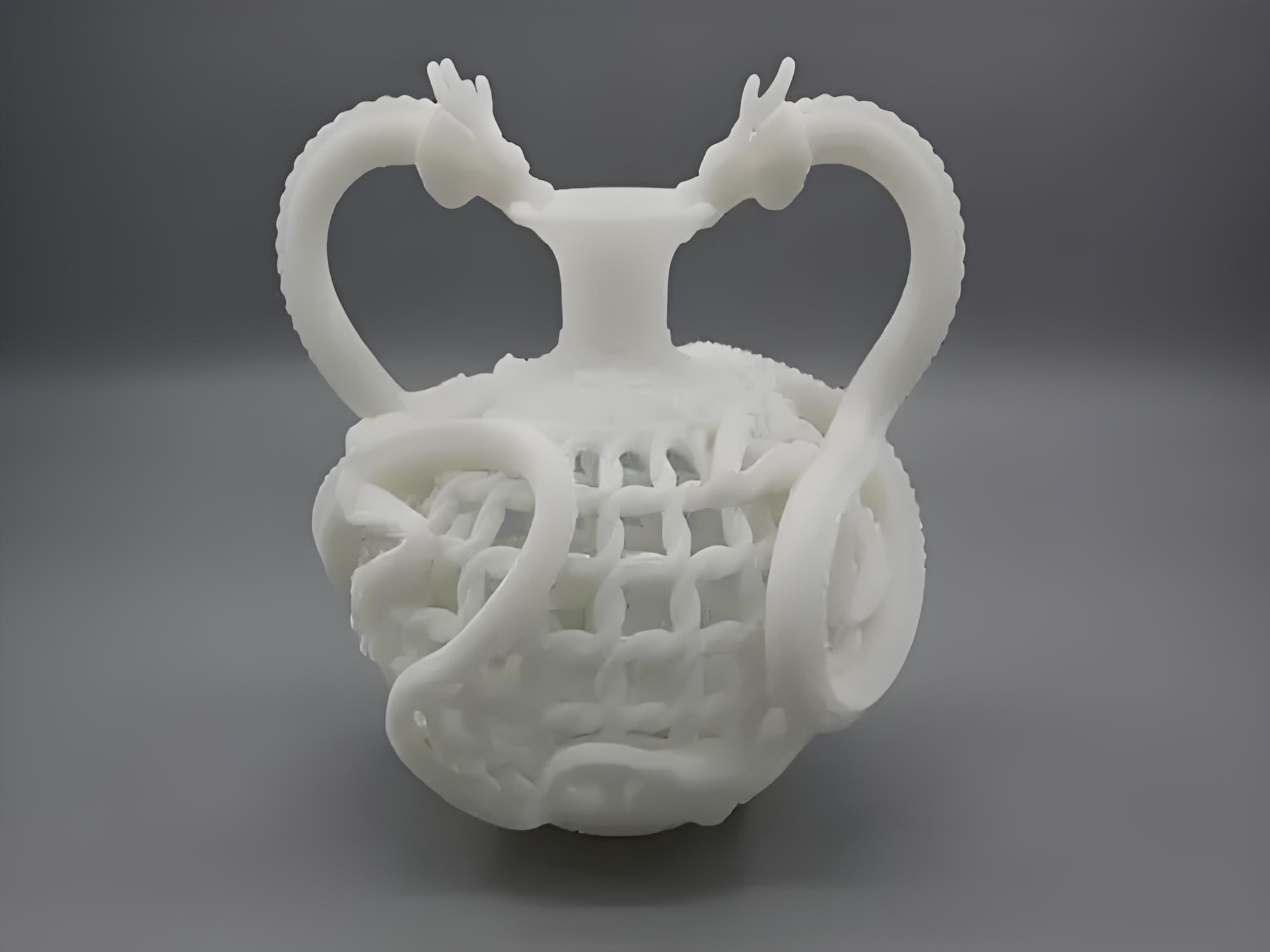

3D Print Parts Polishing

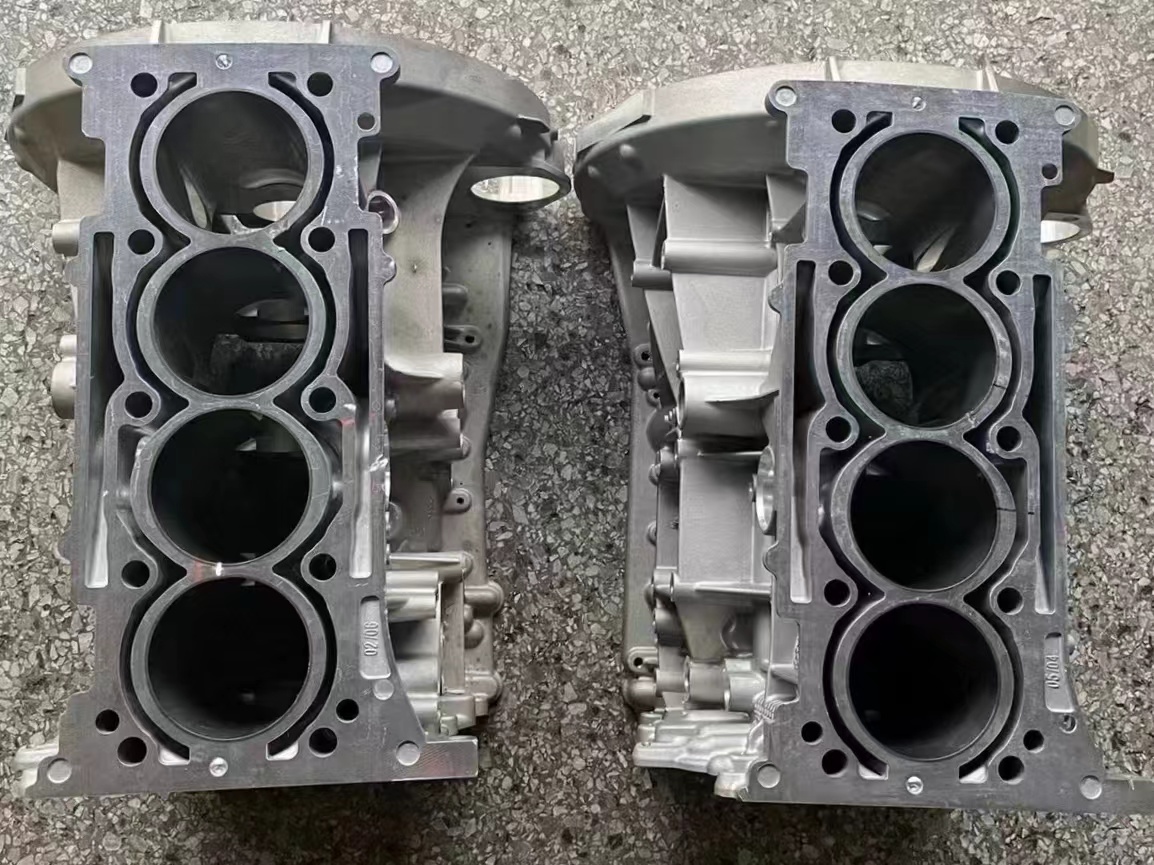

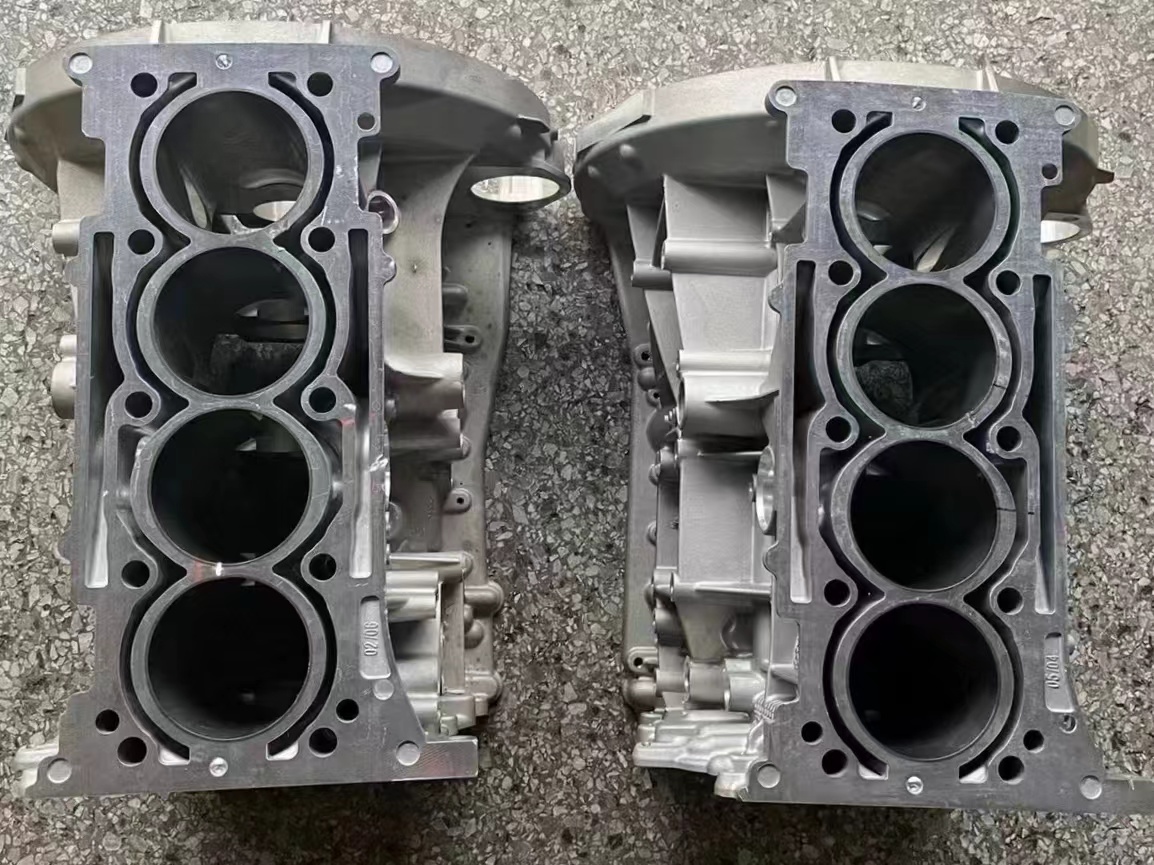

Engine Block Polishing

Intake Manifold Polishing

|

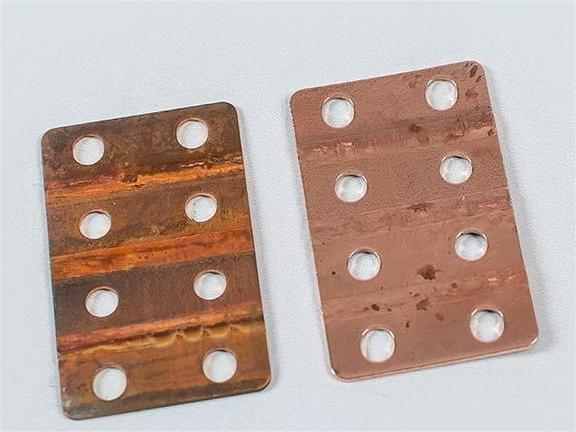

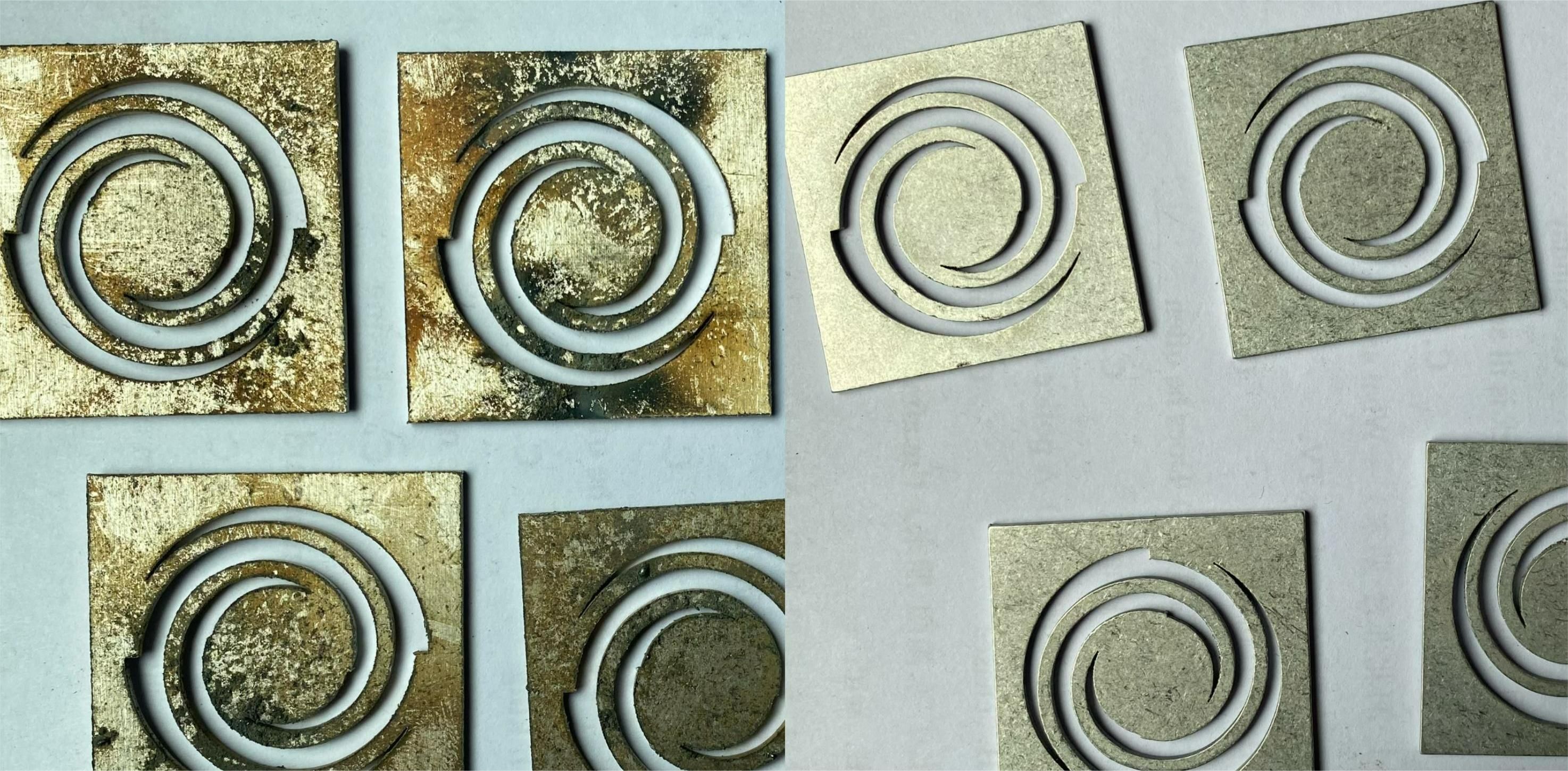

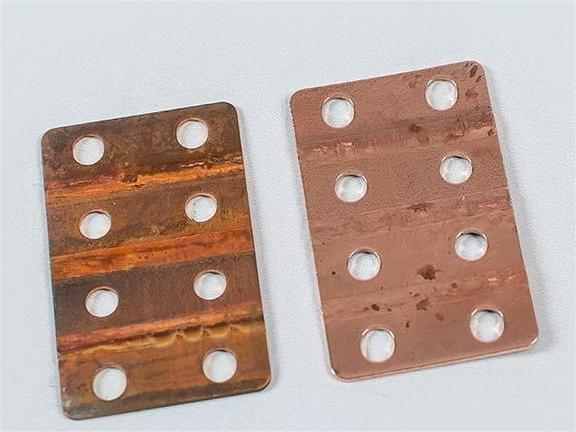

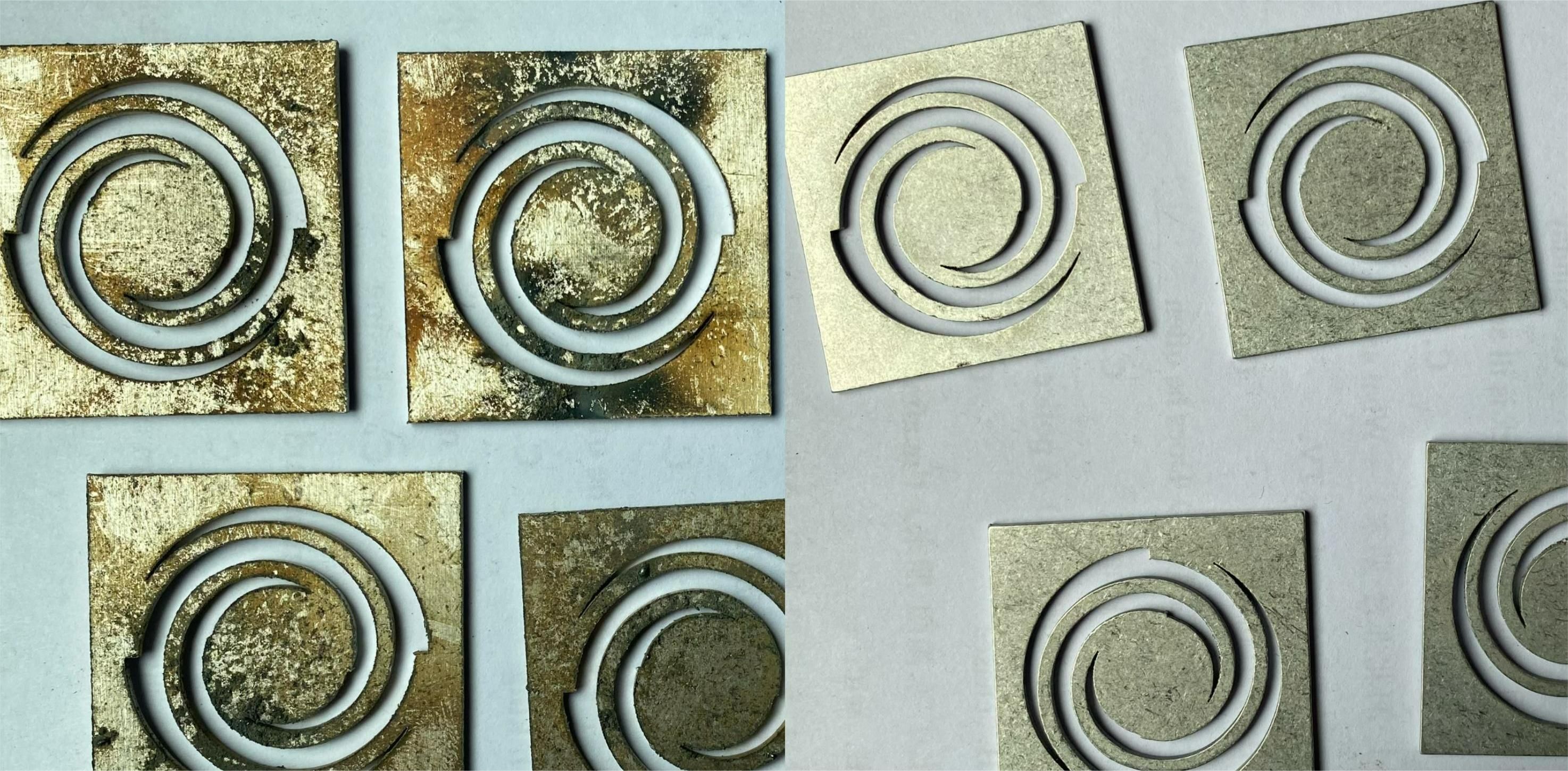

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

This is the general product parameter information we can provide. If you need to customize the size please contact us.

| MODLE | SIZE(MM) | POWER(KW) |

| ND-1 | 640*450*450 | 1.1X2 |

| ND-2 | 850*500*500 | 1.5X2 |

| ND-3 | 850*500*500 | 1.1X2 |

| ND-4 | 1000*380*450 | 1.1X2 |

| ND-5 | 1300*500*500 | 1.5X2 |

| ND-6 | 1200*600*600 | 2.2X2 |

| ND-7 | 1000*550*600 | 1.5X2 |

| ND-8 | 1300*300*400 | 1.1X2 |

| ND-9 | 1300*670*700 | 3.0X2 |

| ND-10 | 1460*520*600 | 2.2X2 |

| ND-11 | 1650*500*550 | 3.0X2 |

| ND-12 | 920*850*750 | 3.0X2 |

| ND-13 | 850*620*600 | 2.2X2 |

| ND-14 | 900*920*800 | 3.0X2 |

| ND-15 | 1000*420*450 | 1.5X2 |

| ND-16 | 2300*650*750 | 4.0X2 |

| ND-17 | 1600*700*700 | 4.0X2 |

| ND-18 | 2000*910*850 | 5.5X2 |

| ND-19 | 2500*550*600 | 4.4X2 |

| ND-20 | 800*800*700 | 3.0X2 |

| ND-21 | 900*1200*800 | 3.0X2 |

| ND-22 | 800*400*400 | 1.1X2 |

We can provide you with product customization services. We will try our best to help you make the color or special shape you prefer. If you have any special customization needs, you can tell us. We hope that our products can help you in your business.

|

Product Factory Real Show

Spring

Inner Container

Whole Shape

Whole Shape

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment.We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

Nordern is committed to providing you with professional, reliable and efficient logistics solutions to ensure that your goods reach your destination smoothly and quickly.

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Square vibratory polishing machine is mainly composed of a vibration motor, support spring, and base. The vibration motor is fixed to the container with bolts and is placed together on the spring connected to the base. Square vibratory polishing machine is a reform and innovation on the defects of traditional polishing machines. The rolling force is transmitted to various polishing tumbling media to make the products rotate at a high frequency. It makes significantly better effect of polishing and grinding burrs the inner holes, dead corners and small cracks of precision hardware parts.

Norden machinery has been committed to producing and developing high efficiency polishing machines for more than 20 years. We have advanced technology and rich manufacturing experience. Our square vibratory polishing machine have excellent performance.

1.Square vibration polishing machine can complete all the vibration polishing machine grinding products.

For example, the antique treatment of marble slabs and the deburring treatment of metal rods. It can process multiple marble slabs and large metal rods at one time.

2.Suitable for deburring and polishing long, large products.

For pipe fittings and large products ( larger than 40CM), the square vibration polishing machine's advantage can be fully demonstrated. It uses a linear vibration movement, and the polished products are more refined and beautiful.

3.Suitable for surface finishing of complex cavity parts.

After being surface finished by this type of polishing machine, the parts not only maintain their original dimensional accuracy, but also improve the surface roughness accuracy by 1-2 grades.

Square vibratory polishing machine has removable dividers that can be placed to turn a single trough into multiple trough. Your products can be classified by placing dividers before polishing. It can be used to deal with parts that is easy to hurt each other or different types of parts. This contributes to prevent different kinds of parts from colliding with each other. Large and long products can be polished without dividers.

|

Fearures

1. With removable dividers, it can be used to handle products that are prone to scratching each other or products of different types.

2. It achieves semi-automation through an electrical control system, greatly improving work efficiency in stone polishing.

3. It has a PU lining with high wear resistance.

4. There are two motors on the shell container body, providing a smooth and even vibration force.

|

Application

Square vibratory polishing machine can be applied to the surface polishing, chamfering, deburring, polishing and brightening of small or big size parts. It does not affect the original dimensional accuracy of the product after grinding treatment. It lays a good foundation for some products subsequent electroplating, spraying and other surface treatment. Here are some parts can be polished by square vibratory polishing machine.

Connecting Rods Polishing

Valve covers polishing

Camshaft Polishing

Crankshaft Polishing

Turbo Polishing

Exhaust Pipe Polishing

Golf clubs polishing

Cutlery Polishing

Bike Frame Polishing

3D Print Parts Polishing

Engine Block Polishing

Intake Manifold Polishing

|

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

This is the general product parameter information we can provide. If you need to customize the size please contact us.

| MODLE | SIZE(MM) | POWER(KW) |

| ND-1 | 640*450*450 | 1.1X2 |

| ND-2 | 850*500*500 | 1.5X2 |

| ND-3 | 850*500*500 | 1.1X2 |

| ND-4 | 1000*380*450 | 1.1X2 |

| ND-5 | 1300*500*500 | 1.5X2 |

| ND-6 | 1200*600*600 | 2.2X2 |

| ND-7 | 1000*550*600 | 1.5X2 |

| ND-8 | 1300*300*400 | 1.1X2 |

| ND-9 | 1300*670*700 | 3.0X2 |

| ND-10 | 1460*520*600 | 2.2X2 |

| ND-11 | 1650*500*550 | 3.0X2 |

| ND-12 | 920*850*750 | 3.0X2 |

| ND-13 | 850*620*600 | 2.2X2 |

| ND-14 | 900*920*800 | 3.0X2 |

| ND-15 | 1000*420*450 | 1.5X2 |

| ND-16 | 2300*650*750 | 4.0X2 |

| ND-17 | 1600*700*700 | 4.0X2 |

| ND-18 | 2000*910*850 | 5.5X2 |

| ND-19 | 2500*550*600 | 4.4X2 |

| ND-20 | 800*800*700 | 3.0X2 |

| ND-21 | 900*1200*800 | 3.0X2 |

| ND-22 | 800*400*400 | 1.1X2 |

We can provide you with product customization services. We will try our best to help you make the color or special shape you prefer. If you have any special customization needs, you can tell us. We hope that our products can help you in your business.

|

Product Factory Real Show

Spring

Inner Container

Whole Shape

Whole Shape

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment.We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

Nordern is committed to providing you with professional, reliable and efficient logistics solutions to ensure that your goods reach your destination smoothly and quickly.

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case