- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

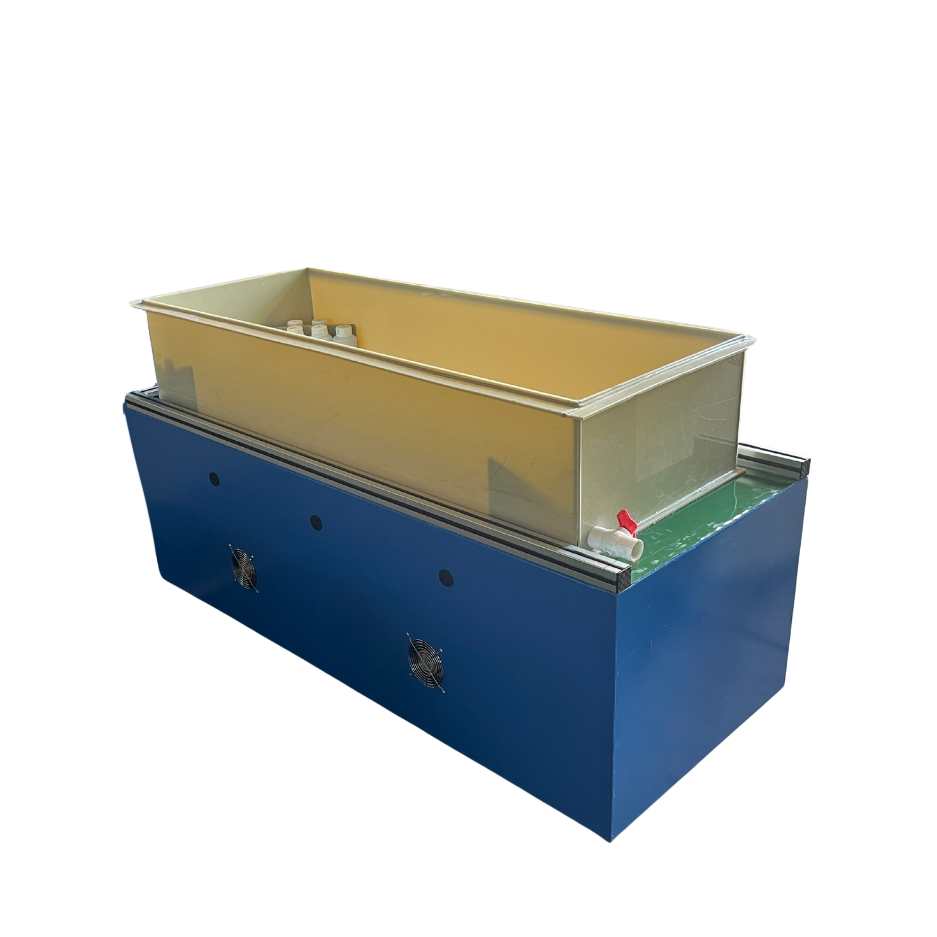

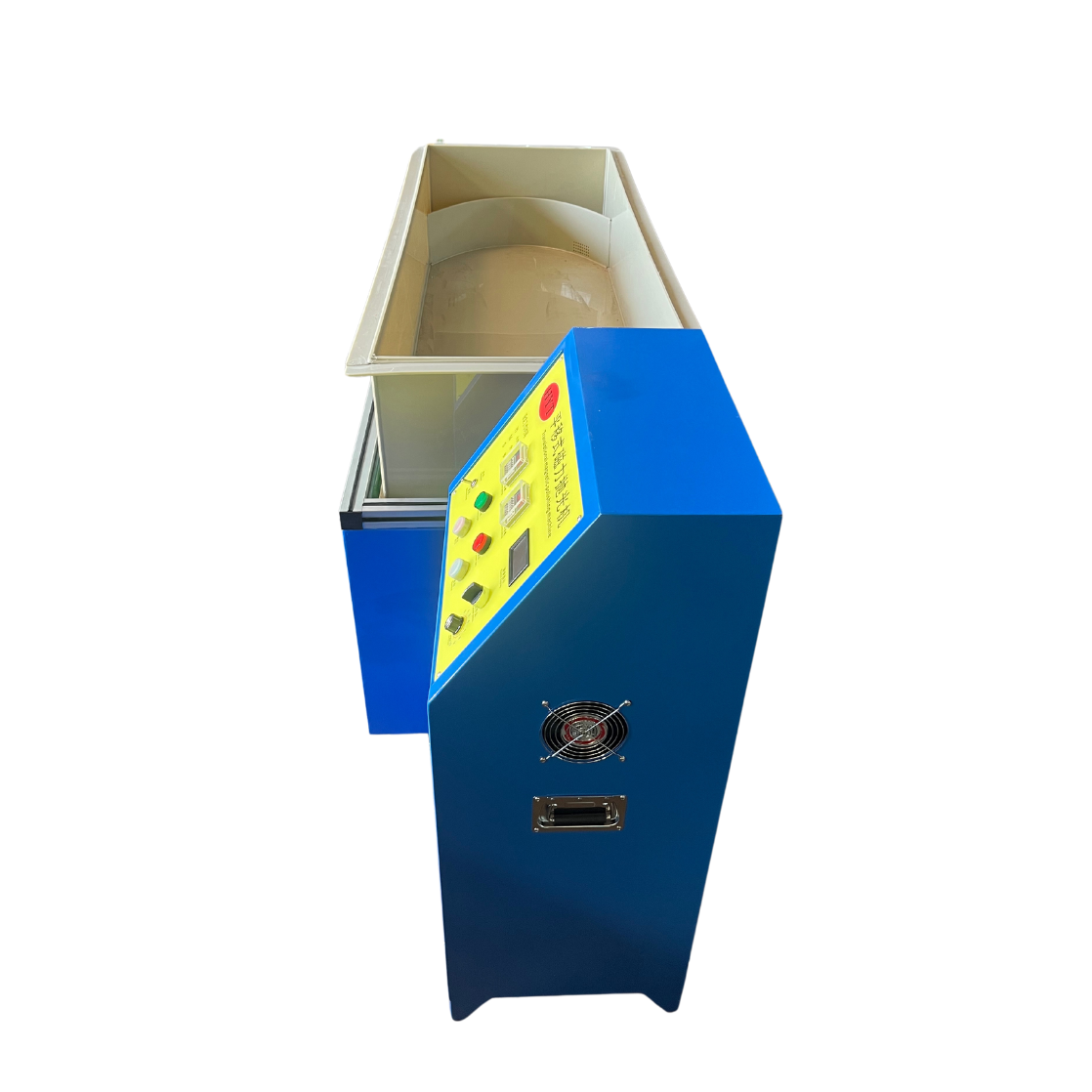

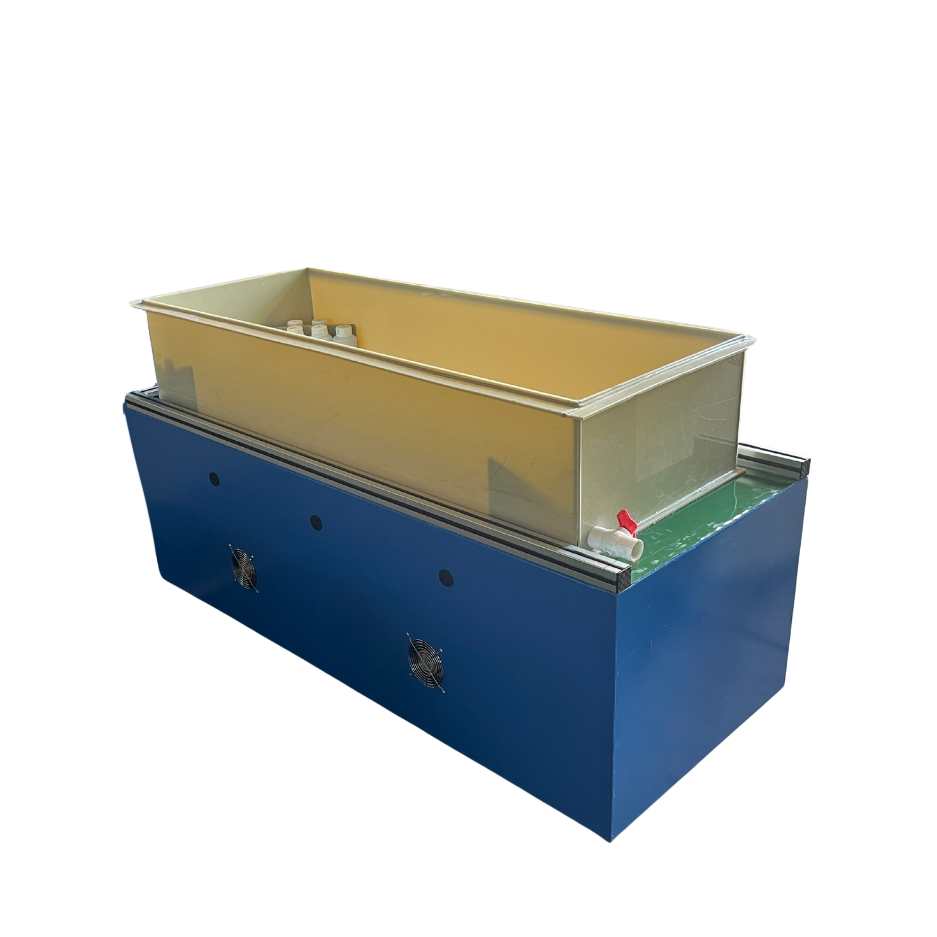

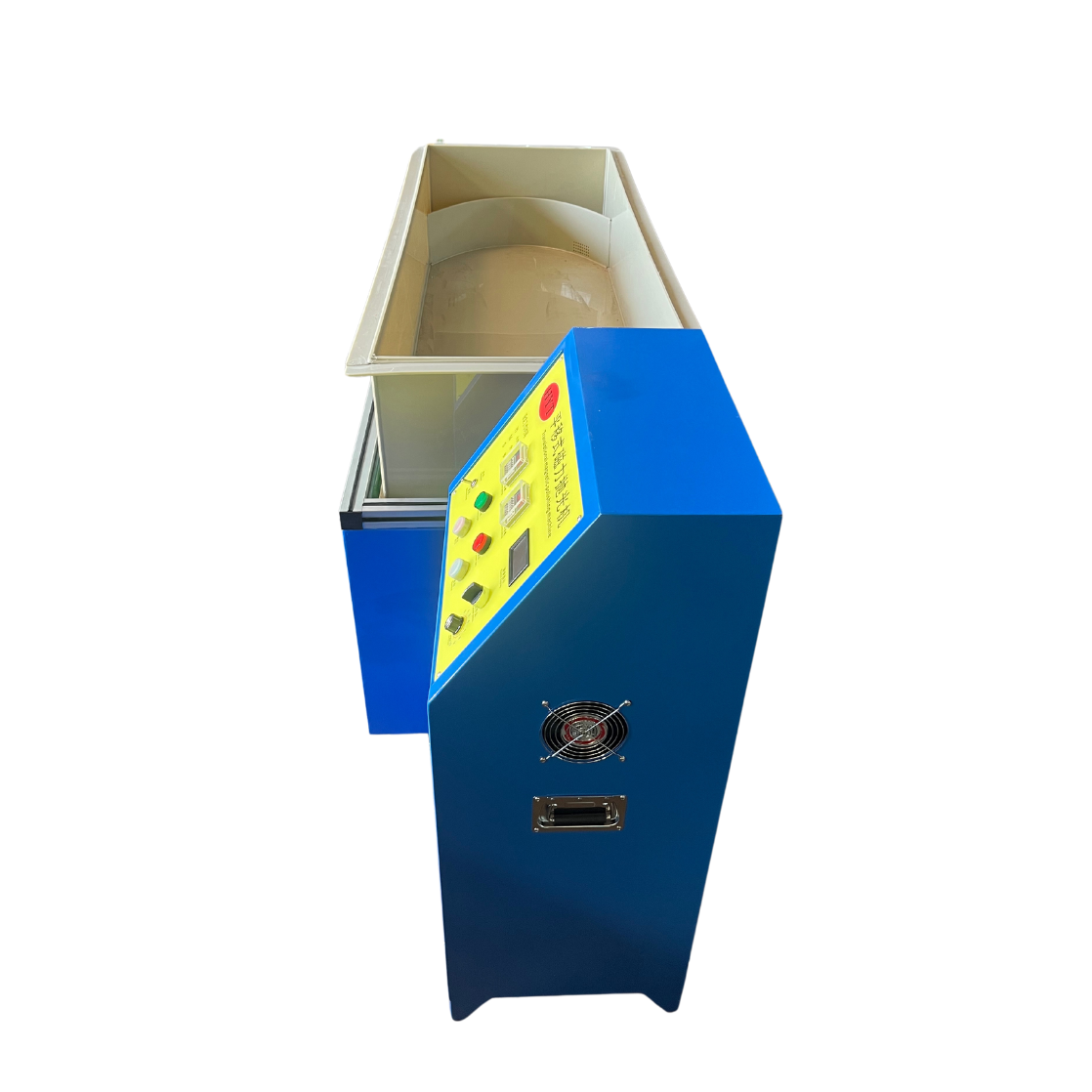

RECTANGLE MPM

Norden

|

Product Description

Norden can provide you with different models of magnetic polishing machine. Different sizes of machines are suitable for polishing different sizes of metal parts. Rectangle magnetic polishing machine is more suited for polishing large and long products. It can solve the conventional cylindrical magnetic polishing machine product processing is not in place and the product can not be put down.

Norden machinery has been committed to manufacturing magnetic grinder for more than 20 years. We have professional team and rich producing experience. Our magnetic polishing machine have high polishing performance. Magnetic polishing machine from Norden can use the tiny magnetic polishing needle to fine grind metal parts inside holes, cracks, grooves, dead corners. However, it is difficult for traditional grinding machines to grind parts with grooves and dead corners in place. The polishing speed is also faster than traditional vibratory polishing machine. It can finish the polishing work about 5-20 minutes or so.

GRINDING TUMBLER

Adopt SUS304 stainless steel

INDUSTRIAL HANDRAIL

Convenient and durable

Portable and mobile

MOVING PULLEY DESIGN

Easy to move product location

RECTANGLE MAGNETIC POLISHING MACHINE

Suitable for large and long products

Large Capacity and high polishing efficiency

Complete functions and simple operation

| Feature

1. The machine is thick and durable to make it easily cope with a variety of harsh environments.

2. The machine is equipped with a control panel, so that you can operate the machine more easily and quickly. One person can operate several machines at the same time to improve polishing efficiency.

3. Using the magnetic field to produce high-speed rotating motion to achieve the effect of polishing and removing burrs.

4. Suitable for polishing large quantities of medium and small size parts.

5. Using the industrial special motor which has good speed performance and excellent drive maintenance rate.

6. The original size and shape of the parts will not be damaged during polishing process.

|

Application

Magnetic polishing machine from Norden machinery has high performance. It is suitable for polishing, cleaning and deburring of your products.

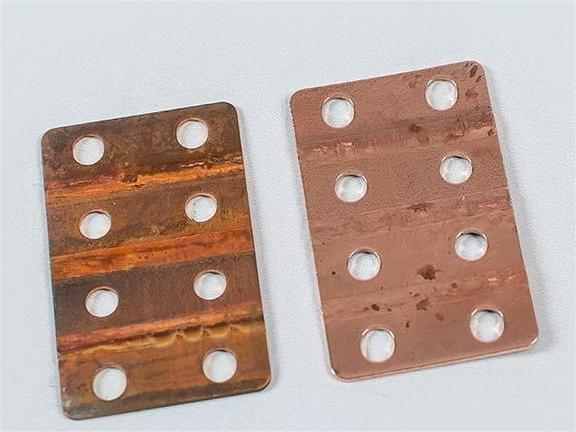

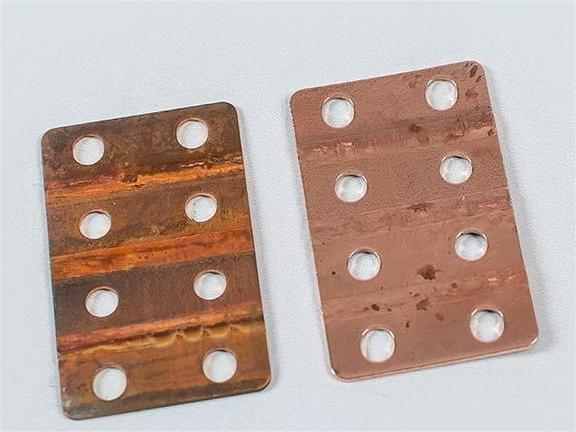

Polishing: It can quickly and evenly remove the oxide layer and small scratches on the surface of the parts to make the surface smooth like a mirror and improve the corrosion resistance.

Cleaning: It can effectively clean the oil, dust and other pollutants on the surface. It is suitable for subsequent processing and assembly of precision parts.

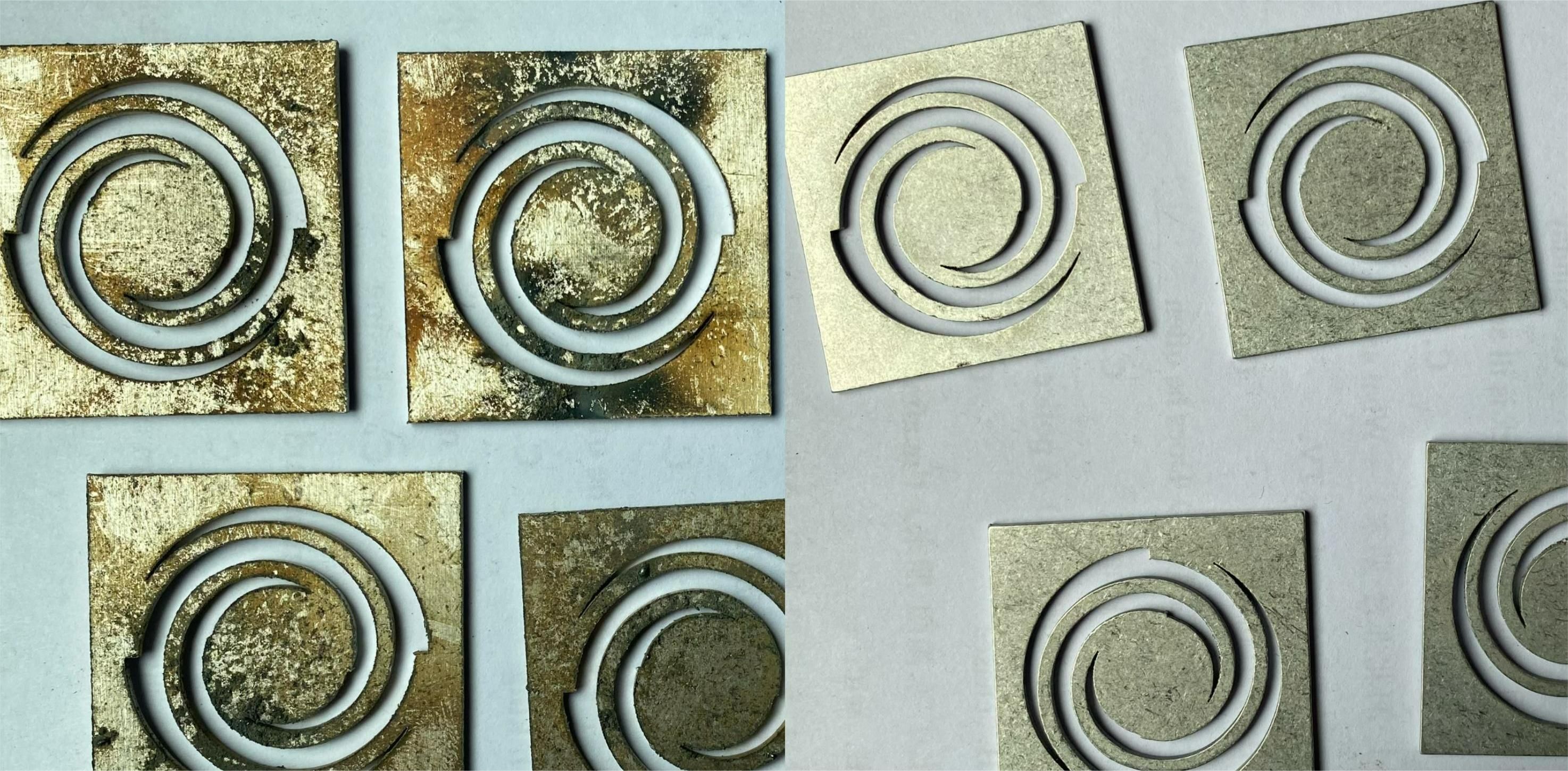

Deburring: It can use magnetic grinding media to fine polishing and completely remove burrs.

Magnetic polishing machine have a wide application in may industries. It mainly includes the following aspects.

1. Automatic parts: engine parts, car shell, camshaft, crankshaft, turbo, connecting rods, exhaust pipe etc.

2. Medical instruments: such as surgical instruments, stents etc to ensure high precision surface polishing treatment.

3. Jewelry polishing: such as pendants, earrings, necklaces, rings, chains, bracelets, pearls, silverware etc.

4. Cutlery polishing, such as spoons, forks and knives.

5. Rust removal and deburring hardware tools.

6. Electronic components finishing.

7. Laser cut parts polishing.

8. 3D print parts polishing.

9. ...

|

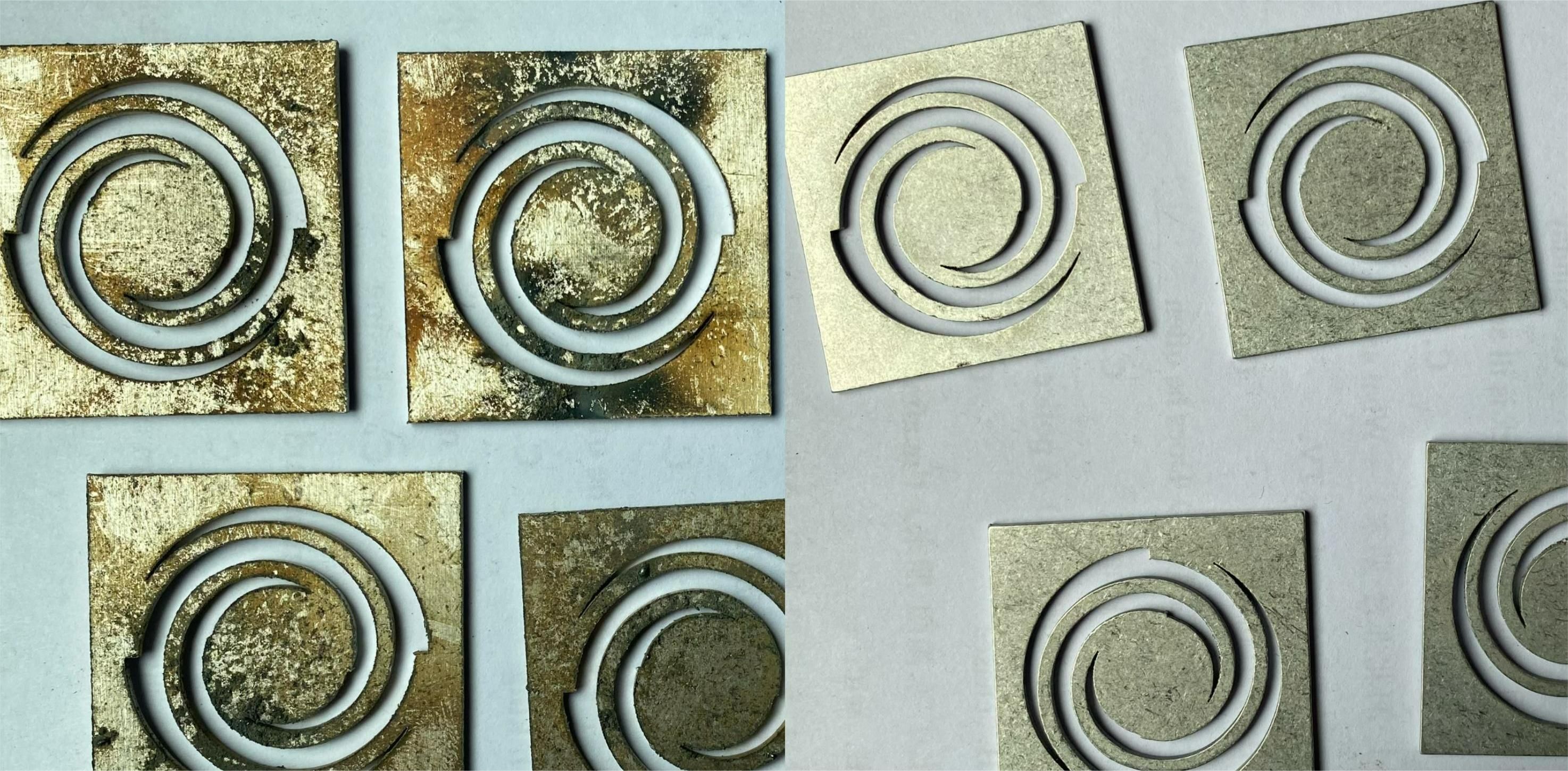

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general magnetic polishing machine parameter information we can provide. If you need to customize the size please contact us. We can provide you with product customization services. We will do our best to make the color or special shape you need. We hope that our magnetic polishing machine can help you in your business.

| Model | L*W*H (CM) | Voltage (KW) | Power (KW) | SPEED (RPM) | Weight (KG) | DIAMETER (CM) | NEEDLES (KG) |

| 10T MPM | 28*28*36 | 220 | 0.37 | 0-1800 | 26 | 21 | 0.1-0.3 |

| 16T MPM | 32*32*38 | 220 | 0.55 | 0-1800 | 34 | 26 | 0.2-0.4 |

| 16T INVERTER MPM | 32*32*38 | 220 | 0.75 | 0-1800 | 35 | 26 | 0.2-0.5 |

| 24T MPM | 40*40*43 | 220 | 0.75 | 0-1800 | 55 | 36 | 0.2-0.8 |

| 24T INVERTER MPM | 40*40*43 | 220 | 1.5 | 0-1800 | 55 | 36 | 0.3-1 |

| 360C INVERTER MPM | 53*41*80 | 220 | 1.5 | 0-1800 | 58 | 36 | 0.3-1 |

| 24T MPM | 53*41*80 | 220 | 1.5 | 0-1800 | 57 | 36 | 0.3-0.8 |

| 360D MPM | 60*50*100 | 380 | 1.5 | 0-1800 | 100 | 40 | 0.1-2 |

| 680D MPM | 80*70*115 | 380 | 2.2 | 0-1800 | 140 | 50 | 0.1-3 |

| 880D MPM | 80*100*118 | 380 | 4 | 0-1800 | 185 | 60 | 0.1-5 |

| RECTANGLE MPM | 100*70*70 | 380 | 4 | 0-1800 | 88*61*30 | 0.1-5 | |

| DOUBLE RECTANGLE MPM | 170*70*70 | 380 | 4 | 0-1800 | 158*61*30 | 0.1-8 |

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Norden can provide you with different models of magnetic polishing machine. Different sizes of machines are suitable for polishing different sizes of metal parts. Rectangle magnetic polishing machine is more suited for polishing large and long products. It can solve the conventional cylindrical magnetic polishing machine product processing is not in place and the product can not be put down.

Norden machinery has been committed to manufacturing magnetic grinder for more than 20 years. We have professional team and rich producing experience. Our magnetic polishing machine have high polishing performance. Magnetic polishing machine from Norden can use the tiny magnetic polishing needle to fine grind metal parts inside holes, cracks, grooves, dead corners. However, it is difficult for traditional grinding machines to grind parts with grooves and dead corners in place. The polishing speed is also faster than traditional vibratory polishing machine. It can finish the polishing work about 5-20 minutes or so.

GRINDING TUMBLER

Adopt SUS304 stainless steel

INDUSTRIAL HANDRAIL

Convenient and durable

Portable and mobile

MOVING PULLEY DESIGN

Easy to move product location

RECTANGLE MAGNETIC POLISHING MACHINE

Suitable for large and long products

Large Capacity and high polishing efficiency

Complete functions and simple operation

| Feature

1. The machine is thick and durable to make it easily cope with a variety of harsh environments.

2. The machine is equipped with a control panel, so that you can operate the machine more easily and quickly. One person can operate several machines at the same time to improve polishing efficiency.

3. Using the magnetic field to produce high-speed rotating motion to achieve the effect of polishing and removing burrs.

4. Suitable for polishing large quantities of medium and small size parts.

5. Using the industrial special motor which has good speed performance and excellent drive maintenance rate.

6. The original size and shape of the parts will not be damaged during polishing process.

|

Application

Magnetic polishing machine from Norden machinery has high performance. It is suitable for polishing, cleaning and deburring of your products.

Polishing: It can quickly and evenly remove the oxide layer and small scratches on the surface of the parts to make the surface smooth like a mirror and improve the corrosion resistance.

Cleaning: It can effectively clean the oil, dust and other pollutants on the surface. It is suitable for subsequent processing and assembly of precision parts.

Deburring: It can use magnetic grinding media to fine polishing and completely remove burrs.

Magnetic polishing machine have a wide application in may industries. It mainly includes the following aspects.

1. Automatic parts: engine parts, car shell, camshaft, crankshaft, turbo, connecting rods, exhaust pipe etc.

2. Medical instruments: such as surgical instruments, stents etc to ensure high precision surface polishing treatment.

3. Jewelry polishing: such as pendants, earrings, necklaces, rings, chains, bracelets, pearls, silverware etc.

4. Cutlery polishing, such as spoons, forks and knives.

5. Rust removal and deburring hardware tools.

6. Electronic components finishing.

7. Laser cut parts polishing.

8. 3D print parts polishing.

9. ...

|

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general magnetic polishing machine parameter information we can provide. If you need to customize the size please contact us. We can provide you with product customization services. We will do our best to make the color or special shape you need. We hope that our magnetic polishing machine can help you in your business.

| Model | L*W*H (CM) | Voltage (KW) | Power (KW) | SPEED (RPM) | Weight (KG) | DIAMETER (CM) | NEEDLES (KG) |

| 10T MPM | 28*28*36 | 220 | 0.37 | 0-1800 | 26 | 21 | 0.1-0.3 |

| 16T MPM | 32*32*38 | 220 | 0.55 | 0-1800 | 34 | 26 | 0.2-0.4 |

| 16T INVERTER MPM | 32*32*38 | 220 | 0.75 | 0-1800 | 35 | 26 | 0.2-0.5 |

| 24T MPM | 40*40*43 | 220 | 0.75 | 0-1800 | 55 | 36 | 0.2-0.8 |

| 24T INVERTER MPM | 40*40*43 | 220 | 1.5 | 0-1800 | 55 | 36 | 0.3-1 |

| 360C INVERTER MPM | 53*41*80 | 220 | 1.5 | 0-1800 | 58 | 36 | 0.3-1 |

| 24T MPM | 53*41*80 | 220 | 1.5 | 0-1800 | 57 | 36 | 0.3-0.8 |

| 360D MPM | 60*50*100 | 380 | 1.5 | 0-1800 | 100 | 40 | 0.1-2 |

| 680D MPM | 80*70*115 | 380 | 2.2 | 0-1800 | 140 | 50 | 0.1-3 |

| 880D MPM | 80*100*118 | 380 | 4 | 0-1800 | 185 | 60 | 0.1-5 |

| RECTANGLE MPM | 100*70*70 | 380 | 4 | 0-1800 | 88*61*30 | 0.1-5 | |

| DOUBLE RECTANGLE MPM | 170*70*70 | 380 | 4 | 0-1800 | 158*61*30 | 0.1-8 |

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case