- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

150L

Norden

|

Product Description

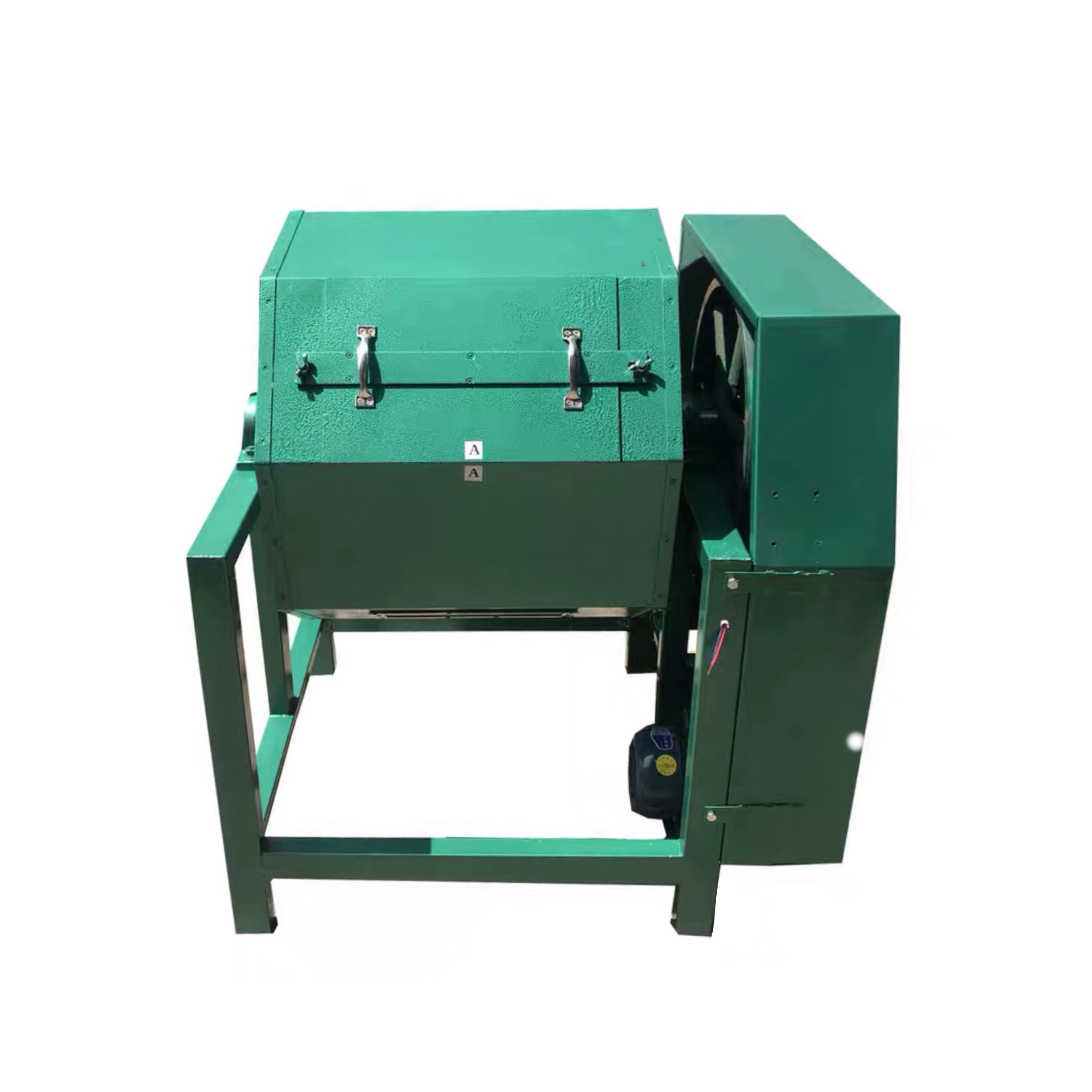

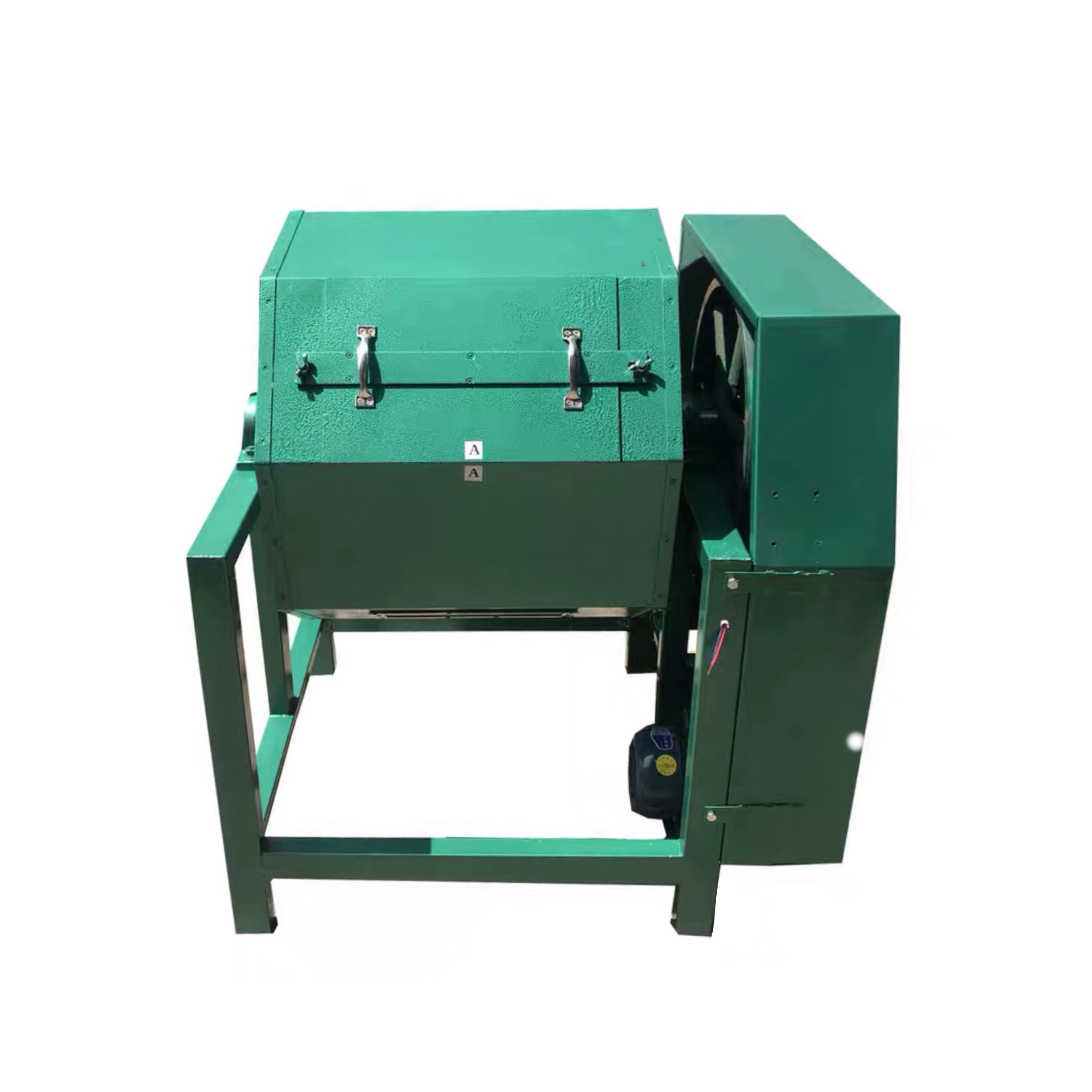

Tumbling machine is widely used in metal processing, ceramic products, plastic products and other industries. It also can be used for cleaning casting and forging parts, riveting and welding parts. It is also suitable for fine grinding and smooth polishing of the sharp edge of the surface of metal products.

150L FRONT

150L BACK

300L FRONT

300L BACK

600L FRONT

600L BACK

Norden machinery has been researching and developing polishing machines for more than 20 years. We has rich experience in producing high performance polishing machine. The tumbling machine from Norden machinery has the following features.

1. The product can achieve the polishing effect of the cloth wheel and polishing the blind angle.

2. Regular positive inversion to ensure smooth operation and consistency of the product.

3. Equipped with discharge door and sorting screen to improve work efficiency.

4. The internal grinding machine barrel with large processing capacity can be simultaneously fine grinding and super fine grinding polishing.

5. The grinding barrel body is provided with air holes to ensure a stable and moderate temperature.

6. Easy to operate and can operate continuously for 24 hours.

7. Variable frequency controller can be added as required.

| Feature

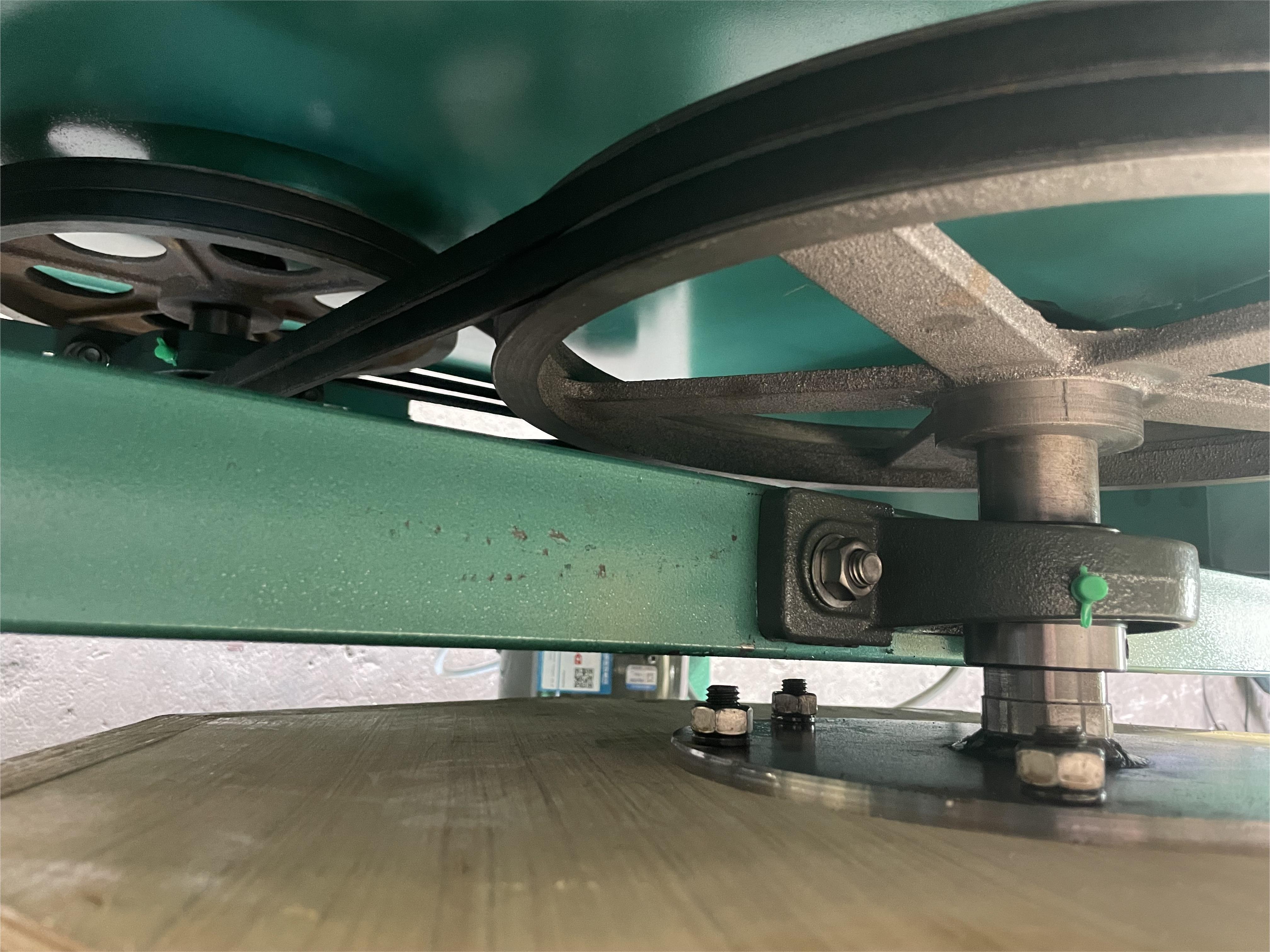

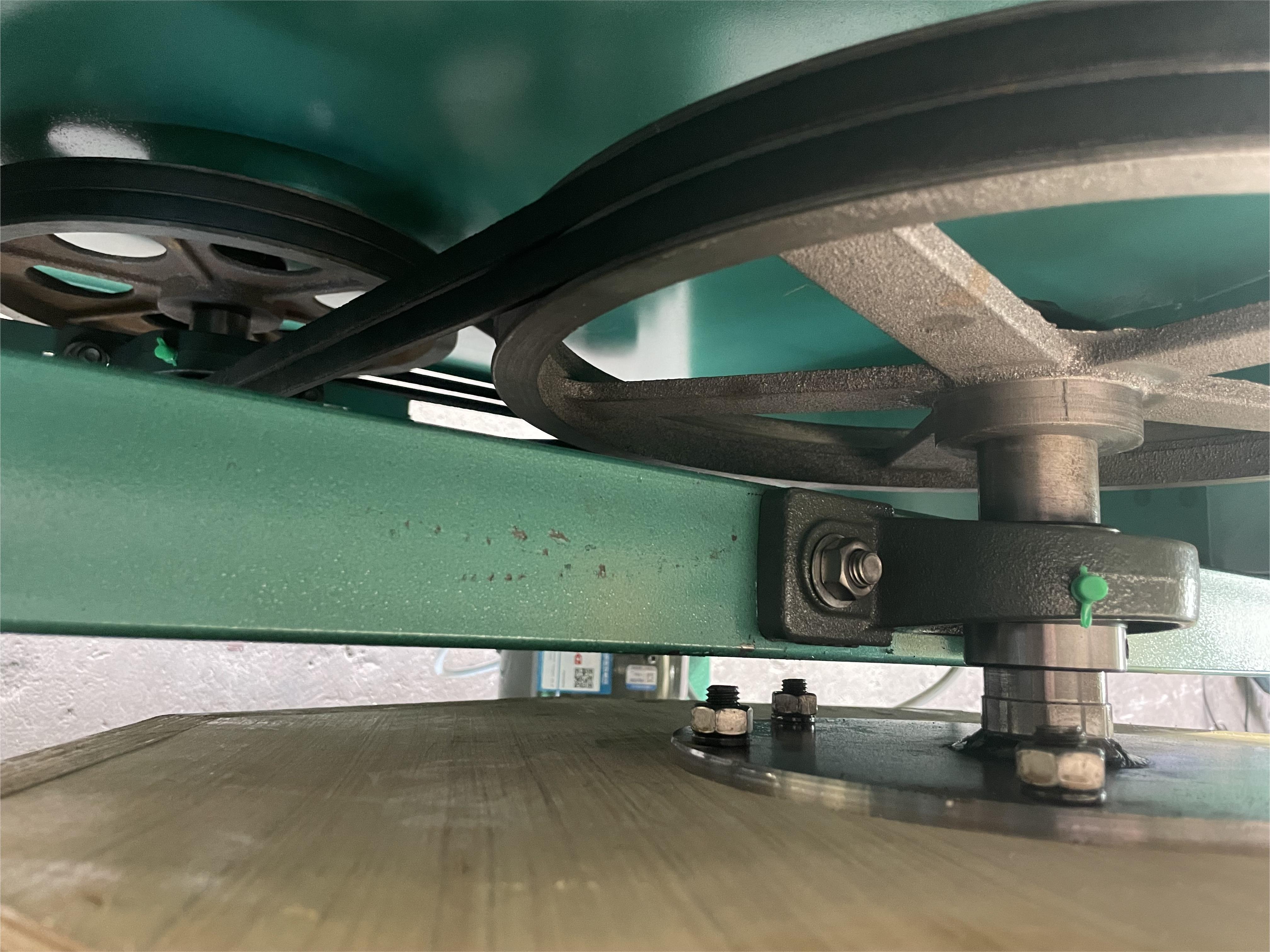

1. Stable and durable steel structure of international standards.

2. Wear and tear resistant, environmental friendly and heat dissipating high density bamboo barrel.

3. Safe and convenient electric control operation.

4. Stable transmission and fine performance with tumbling polishing.

5. Light weight, low production cost, low noise.

6. Green environmental protection, economic and durable.

|

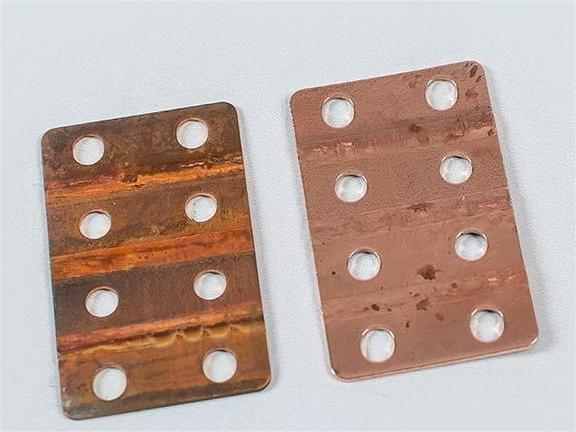

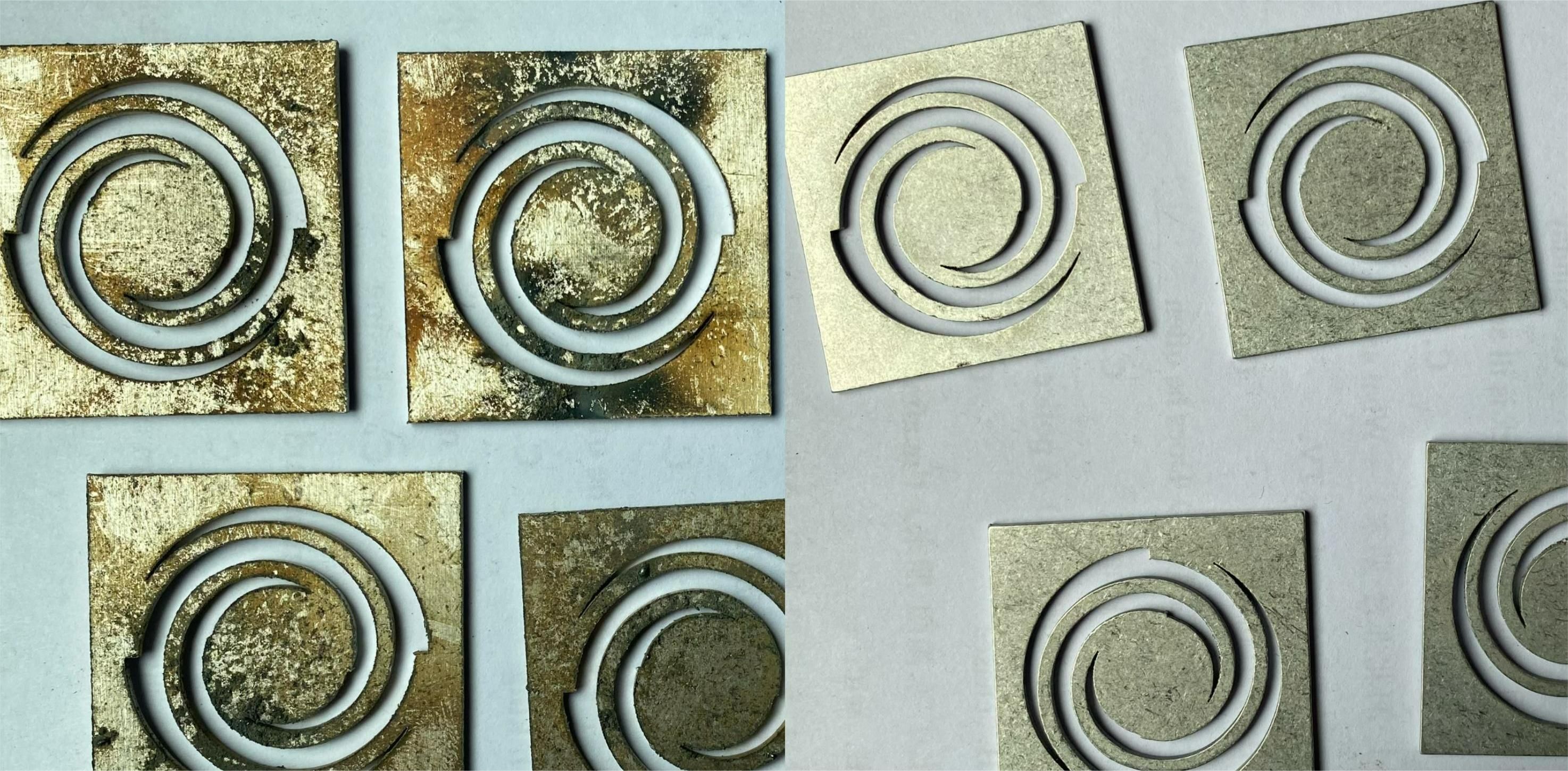

Application

Tumbling polishing machine has a wide application in many industries. It can polish small and middle size products. It is suitable for glasses, watch accessories, jewelry, plastic parts, acrylic, wood products, stainless steel, titanium, copper, aluminum alloy and so on. You can use some tumbling polishing media together to help you get the best grinding effect. Rotating barrel polishing machine from Norden machinery has high polishing and deburring efficiency.

|

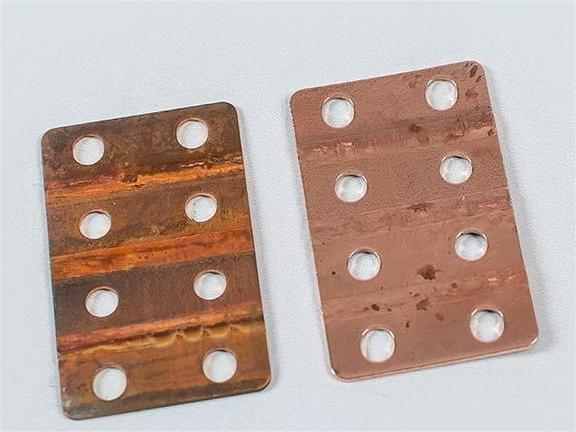

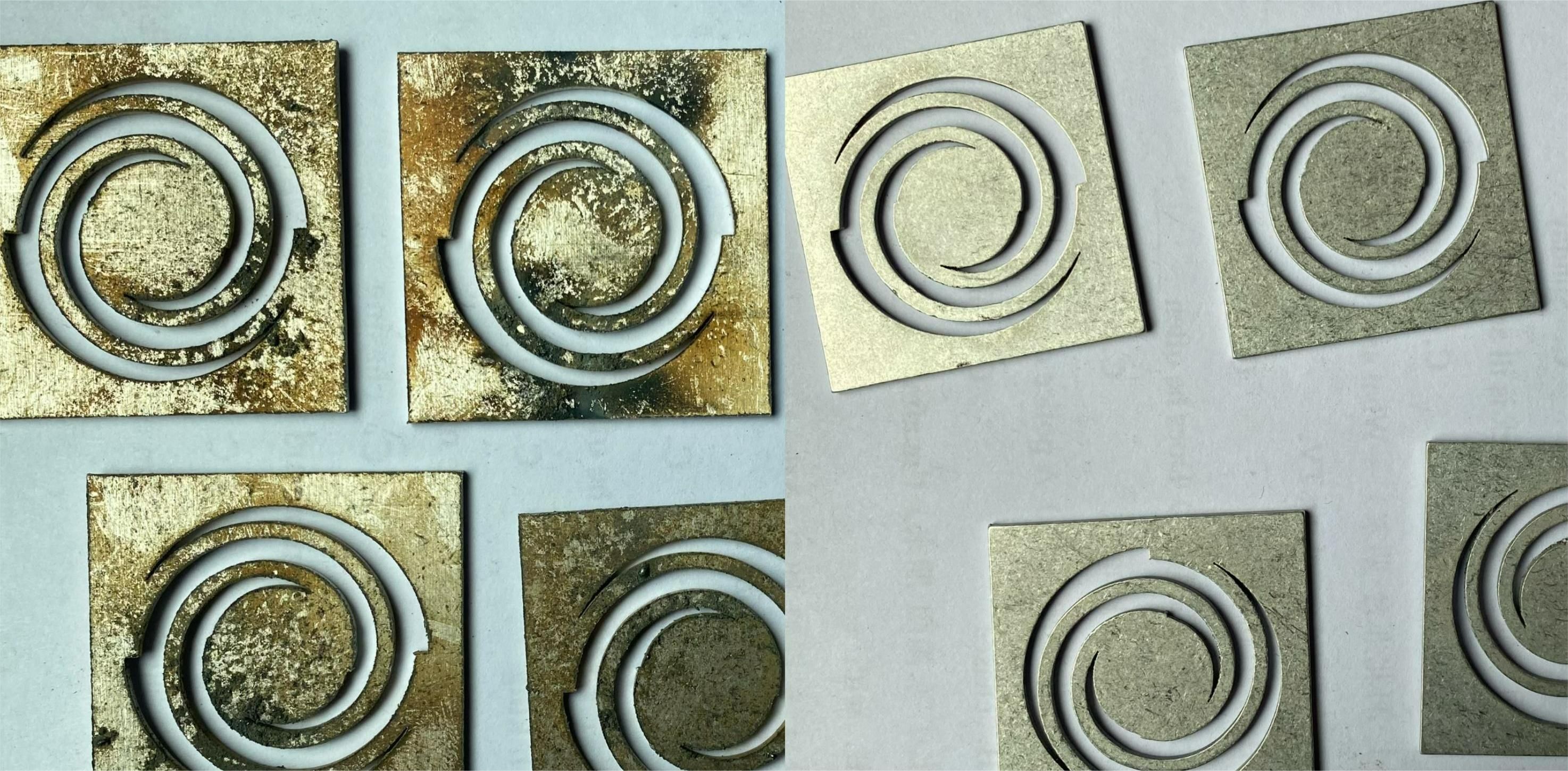

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general tumbling polishing machine parameter information.We truly hope that our tumbling polishing machine can help you in your business.

| Modle | Single Barrel | Single Barrel with Converter | Double Barrel | Double Barrel with Converter |

| Volume(L) | 300 | 300 | 600 | 600 |

| Machine Size(MM) | 1700*800*1200 | 1700*800*1200 | 1700*800*1750 | 1950*800*1750 |

| Barrel Length(MM) | 1120 | 1120 | 1120 | 1120 |

| Barrel Diameter(MM) | 700 | 700 | 700 | 700 |

| Motor Power(KW) | 0.75 | 0.75 | 0.75 | 0.75 |

| Converter Power(KW) | / | 1.5 | / | 1.5 |

| Voltage(V) | 380 | 380/220 | 380 | 380/220 |

| Rotating Speed(R/MIN) | 32 | 32 | 33 | 33 |

We can also provide you with the following machines:

Method of use:

First, pour appropriate amount of polishing abrasive into the roller and add appropriate amount of water, brightener and cleaning agent.

Next, place the products to be polished into the roller and make sure they are evenly distributed.

Then, close the lid of the machine and install the locking rod for safety.

Finally, start the polishing machine and let the roller rotate according to the set speed. During the polishing process, you can adjust the speed and polishing time as needed to achieve the best polishing effect.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Tumbling machine is widely used in metal processing, ceramic products, plastic products and other industries. It also can be used for cleaning casting and forging parts, riveting and welding parts. It is also suitable for fine grinding and smooth polishing of the sharp edge of the surface of metal products.

150L FRONT

150L BACK

300L FRONT

300L BACK

600L FRONT

600L BACK

Norden machinery has been researching and developing polishing machines for more than 20 years. We has rich experience in producing high performance polishing machine. The tumbling machine from Norden machinery has the following features.

1. The product can achieve the polishing effect of the cloth wheel and polishing the blind angle.

2. Regular positive inversion to ensure smooth operation and consistency of the product.

3. Equipped with discharge door and sorting screen to improve work efficiency.

4. The internal grinding machine barrel with large processing capacity can be simultaneously fine grinding and super fine grinding polishing.

5. The grinding barrel body is provided with air holes to ensure a stable and moderate temperature.

6. Easy to operate and can operate continuously for 24 hours.

7. Variable frequency controller can be added as required.

| Feature

1. Stable and durable steel structure of international standards.

2. Wear and tear resistant, environmental friendly and heat dissipating high density bamboo barrel.

3. Safe and convenient electric control operation.

4. Stable transmission and fine performance with tumbling polishing.

5. Light weight, low production cost, low noise.

6. Green environmental protection, economic and durable.

|

Application

Tumbling polishing machine has a wide application in many industries. It can polish small and middle size products. It is suitable for glasses, watch accessories, jewelry, plastic parts, acrylic, wood products, stainless steel, titanium, copper, aluminum alloy and so on. You can use some tumbling polishing media together to help you get the best grinding effect. Rotating barrel polishing machine from Norden machinery has high polishing and deburring efficiency.

|

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general tumbling polishing machine parameter information.We truly hope that our tumbling polishing machine can help you in your business.

| Modle | Single Barrel | Single Barrel with Converter | Double Barrel | Double Barrel with Converter |

| Volume(L) | 300 | 300 | 600 | 600 |

| Machine Size(MM) | 1700*800*1200 | 1700*800*1200 | 1700*800*1750 | 1950*800*1750 |

| Barrel Length(MM) | 1120 | 1120 | 1120 | 1120 |

| Barrel Diameter(MM) | 700 | 700 | 700 | 700 |

| Motor Power(KW) | 0.75 | 0.75 | 0.75 | 0.75 |

| Converter Power(KW) | / | 1.5 | / | 1.5 |

| Voltage(V) | 380 | 380/220 | 380 | 380/220 |

| Rotating Speed(R/MIN) | 32 | 32 | 33 | 33 |

We can also provide you with the following machines:

Method of use:

First, pour appropriate amount of polishing abrasive into the roller and add appropriate amount of water, brightener and cleaning agent.

Next, place the products to be polished into the roller and make sure they are evenly distributed.

Then, close the lid of the machine and install the locking rod for safety.

Finally, start the polishing machine and let the roller rotate according to the set speed. During the polishing process, you can adjust the speed and polishing time as needed to achieve the best polishing effect.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case