- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ND21

Norden

|

Product Description

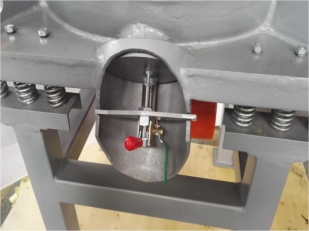

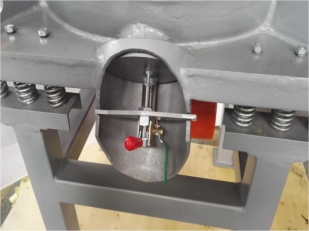

Wheel vibratory polishing machine is specially designed for wheel surface deburring, refurbishing and polishing. It is suitable for alumina wheels, alloy wheels, motorcycle wheels, car wheels, as well as huge truck wheels. Firstly you can fix a single wheel rim inside the machine, and then drive the system to make the wheel rim and polishing abrasives to rotate at high speed. In the polishing process, between the polishing abrasives and the surface of the wheel hub will generate strong friction, so as to remove the defects and oxidation layers on the surface of the wheel. The surface of the wheel hub can get bright and smooth polishing effects.

Norden machinery has been in manufacturing all kinds of polishing machines more than 20 years. Wheel vibratory polishing machines from Norden machinery have many excellent performance.

The machine can accurately and firmly fix the single wheel rim to ensure that the wheel hub does not shift or shake during the polishing process, thus ensuring the precision and quality of the polishing.

The drive system consists of an electric motor that powers the hub rotation, allowing it to rotate at high speeds for polishing operations.

The machine adopts advanced control system, which can realize the precise control of polishing process. The operator can set polishing parameters through the control panel, such as polishing time, speed, etc., to ensure that each hub can get a consistent polishing effect.

| Feature

1.High automation: The automated operation greatly reduce manual intervention, the labor intensity, and the error and safety risks caused by manual operation.

2.High polishing quality: Due to the precise clamping and control system, the surface of the wheel rim can be polished with high precision, thus improving the performance of the wheel hub.

3.High production efficiency: The work efficiency is much higher than the manual polishing method. It can continuously polish and the polishing time of each wheel rim is relatively fixed. It is suitable for mass polishing production.

4.Wide application: It can be applied to different materials, sizes and shapes of wheels, such as aluminum alloy wheels, steel wheels and so on.

5.Easy to operate: The operation is simple. Through the intuitive control panel, various parameters can be conveniently set and adjusted to make the monitoring and management of the polishing process.

|

Application

Wheel vibratory polishing machines have wide applition.Car repair shop: It can be used to repair and refurbish car wheel hubs to restore the luster of the wheels and enhance the overall appearance of the car. When the car wheel hub is slightly collided, scratched or oxidized after a long time of use, the repair shop can use the wheel hub polishing machine to treat it.

Car modification shop: After personalized modification of the wheel hub, in order to achieve the ideal appearance of the wheel, the wheel polishing machine is usually used for the final surface treatment to make it more beautiful and match the overall modification style.

Automobile wheel manufacturing factory: In the last few processes of wheel manufacturing, the surface of the wheel hub needs to be finely polished to achieve product high quality standards and aesthetic requirements. Wheel hub polishing machine can efficiently complete a large number of wheel hub polishing work.

Motorbike Wheels Polishing

Bicycle Wheels Polishing

Truck Wheels Polishing

Alloy Wheels Polishing

|

Polishing Effect Display

|

Size Information

Here is the general wheel vibratory polishing machine parameter information.We truly hope that our wheel vibratory polishing machine can help you in your business.

| MACHINE MODEL | ND21 | ND25 | ND32 |

| WHEEL SIZE | 0-21 INCH | 0-25 INCH | 0-32 INCH |

| INSIDE DIAMETER | 660MM | 760MM | 860MM |

| BUCHET HEIGHT | 400MM | 400MM | 540MM |

| MOTOR | 0.75X2KW + 0.25KW | 0.75X2KW + 0.40KW | 1.1X2KW + 0.40KW |

| DIMENSION | 1400X950X1220 | 1446X1030X1192 | 1560X1241X1202 |

| AMPLITUDE | 2-5MM | 2-5MM | 2-5MM |

We can also provide you with the following machines:

WHEEL POLISHING MACHINE

Method of using

Wheel vibratory polishing machine is simple and convenient to use, the specific steps are as follows:

First of all, remove the wheel from the car and clean it, and then fix it on the wheel grinding and polishing machine.

Start the polishing equipment and select the appropriate grinding speed according to actual needs.

After the wheel hub is polished, turn off the equipment and remove the wheel for cleaning.

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Wheel vibratory polishing machine is specially designed for wheel surface deburring, refurbishing and polishing. It is suitable for alumina wheels, alloy wheels, motorcycle wheels, car wheels, as well as huge truck wheels. Firstly you can fix a single wheel rim inside the machine, and then drive the system to make the wheel rim and polishing abrasives to rotate at high speed. In the polishing process, between the polishing abrasives and the surface of the wheel hub will generate strong friction, so as to remove the defects and oxidation layers on the surface of the wheel. The surface of the wheel hub can get bright and smooth polishing effects.

Norden machinery has been in manufacturing all kinds of polishing machines more than 20 years. Wheel vibratory polishing machines from Norden machinery have many excellent performance.

The machine can accurately and firmly fix the single wheel rim to ensure that the wheel hub does not shift or shake during the polishing process, thus ensuring the precision and quality of the polishing.

The drive system consists of an electric motor that powers the hub rotation, allowing it to rotate at high speeds for polishing operations.

The machine adopts advanced control system, which can realize the precise control of polishing process. The operator can set polishing parameters through the control panel, such as polishing time, speed, etc., to ensure that each hub can get a consistent polishing effect.

| Feature

1.High automation: The automated operation greatly reduce manual intervention, the labor intensity, and the error and safety risks caused by manual operation.

2.High polishing quality: Due to the precise clamping and control system, the surface of the wheel rim can be polished with high precision, thus improving the performance of the wheel hub.

3.High production efficiency: The work efficiency is much higher than the manual polishing method. It can continuously polish and the polishing time of each wheel rim is relatively fixed. It is suitable for mass polishing production.

4.Wide application: It can be applied to different materials, sizes and shapes of wheels, such as aluminum alloy wheels, steel wheels and so on.

5.Easy to operate: The operation is simple. Through the intuitive control panel, various parameters can be conveniently set and adjusted to make the monitoring and management of the polishing process.

|

Application

Wheel vibratory polishing machines have wide applition.Car repair shop: It can be used to repair and refurbish car wheel hubs to restore the luster of the wheels and enhance the overall appearance of the car. When the car wheel hub is slightly collided, scratched or oxidized after a long time of use, the repair shop can use the wheel hub polishing machine to treat it.

Car modification shop: After personalized modification of the wheel hub, in order to achieve the ideal appearance of the wheel, the wheel polishing machine is usually used for the final surface treatment to make it more beautiful and match the overall modification style.

Automobile wheel manufacturing factory: In the last few processes of wheel manufacturing, the surface of the wheel hub needs to be finely polished to achieve product high quality standards and aesthetic requirements. Wheel hub polishing machine can efficiently complete a large number of wheel hub polishing work.

Motorbike Wheels Polishing

Bicycle Wheels Polishing

Truck Wheels Polishing

Alloy Wheels Polishing

|

Polishing Effect Display

|

Size Information

Here is the general wheel vibratory polishing machine parameter information.We truly hope that our wheel vibratory polishing machine can help you in your business.

| MACHINE MODEL | ND21 | ND25 | ND32 |

| WHEEL SIZE | 0-21 INCH | 0-25 INCH | 0-32 INCH |

| INSIDE DIAMETER | 660MM | 760MM | 860MM |

| BUCHET HEIGHT | 400MM | 400MM | 540MM |

| MOTOR | 0.75X2KW + 0.25KW | 0.75X2KW + 0.40KW | 1.1X2KW + 0.40KW |

| DIMENSION | 1400X950X1220 | 1446X1030X1192 | 1560X1241X1202 |

| AMPLITUDE | 2-5MM | 2-5MM | 2-5MM |

We can also provide you with the following machines:

WHEEL POLISHING MACHINE

Method of using

Wheel vibratory polishing machine is simple and convenient to use, the specific steps are as follows:

First of all, remove the wheel from the car and clean it, and then fix it on the wheel grinding and polishing machine.

Start the polishing equipment and select the appropriate grinding speed according to actual needs.

After the wheel hub is polished, turn off the equipment and remove the wheel for cleaning.

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case