- Home

- Machine

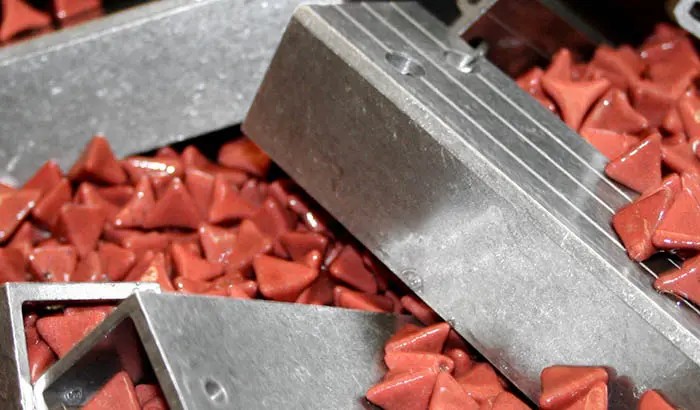

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

150AB

Norden

|

Product Description

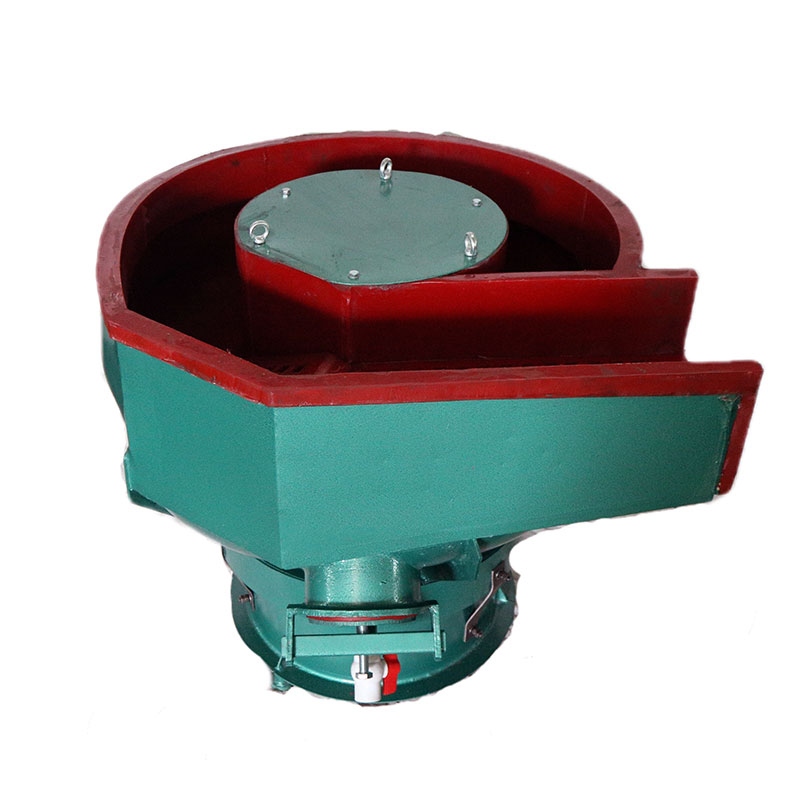

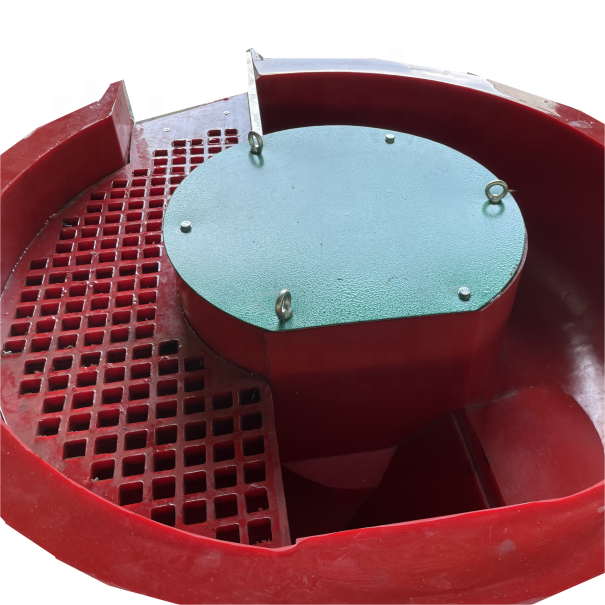

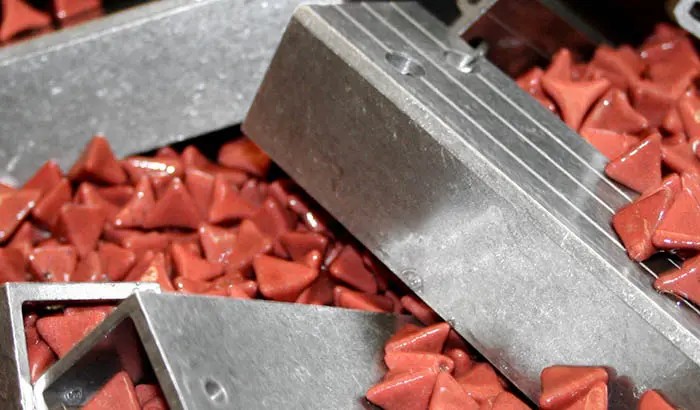

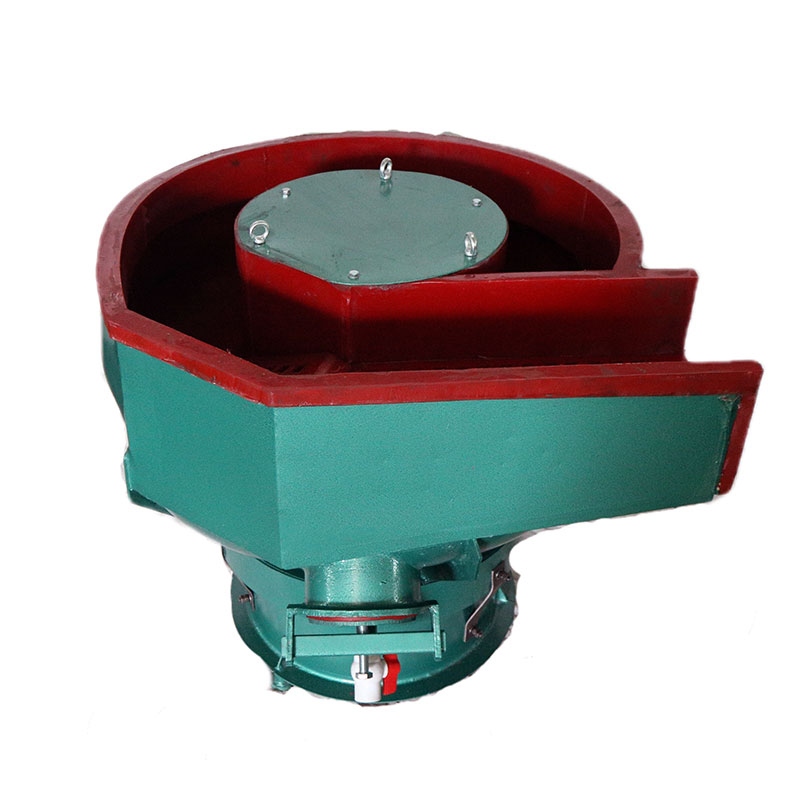

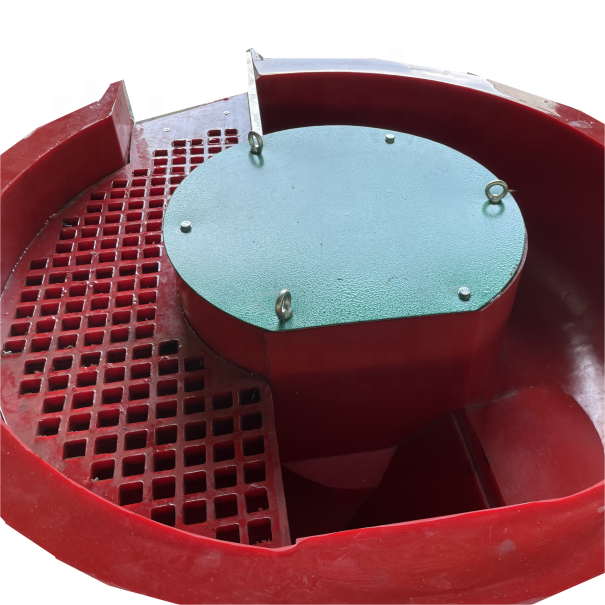

Vibratory polishing machine with separator works on the similar working principle with normal vibratory polishing machine. It adopts the principle of generating three-dimensional high-frequency vibrations within a ring chamber. These vibrations cause the parts and the tumbling polishing media to move in one direction, resulting in friction that facilitates surface grinding. We can provide you the general vibratory polishing machine with separator and curved vibratory polishing machine with separator.

Vibratory Polishing Machine with Separator

Curved Vibratory Polishing Machine with Separator

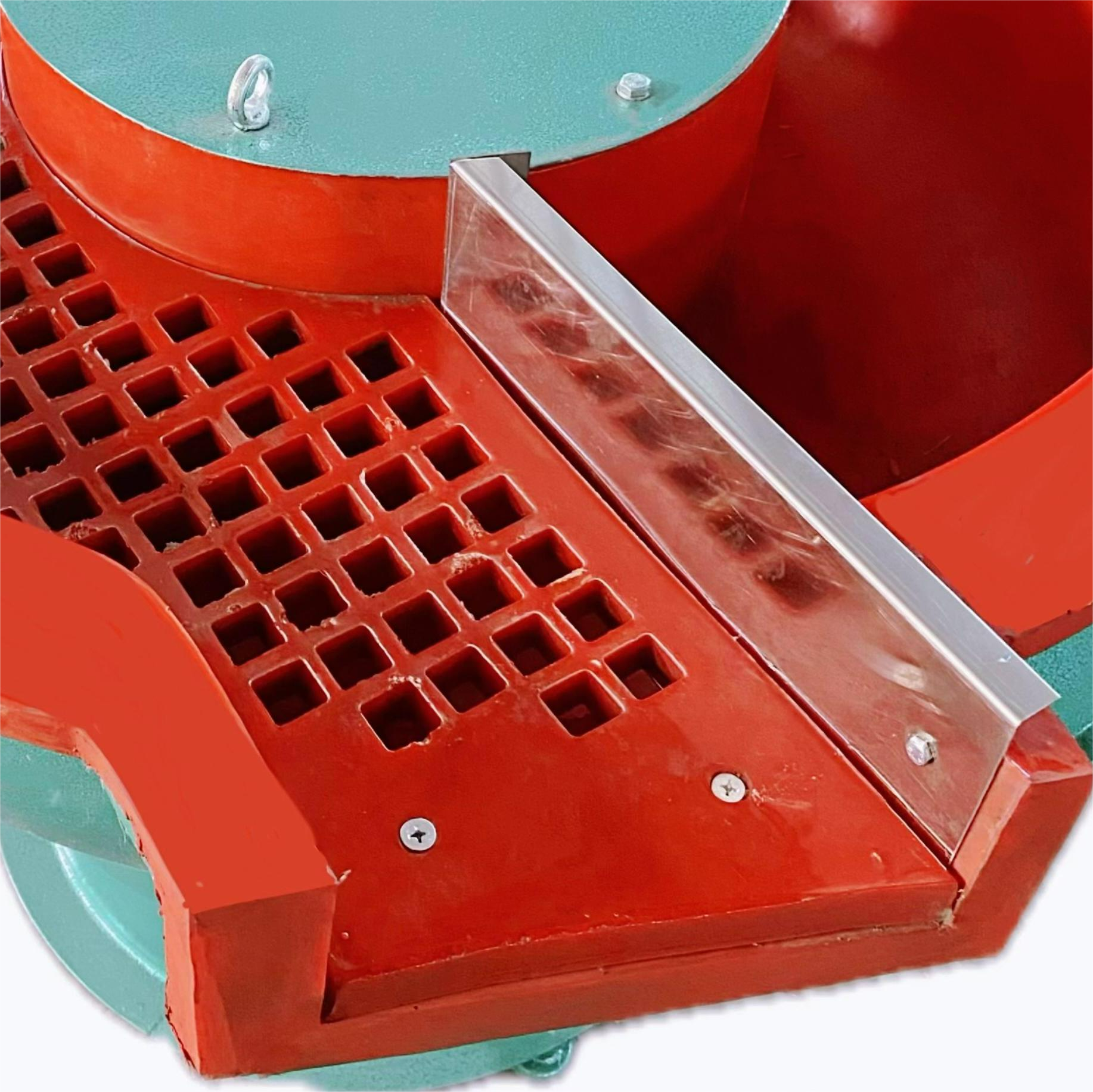

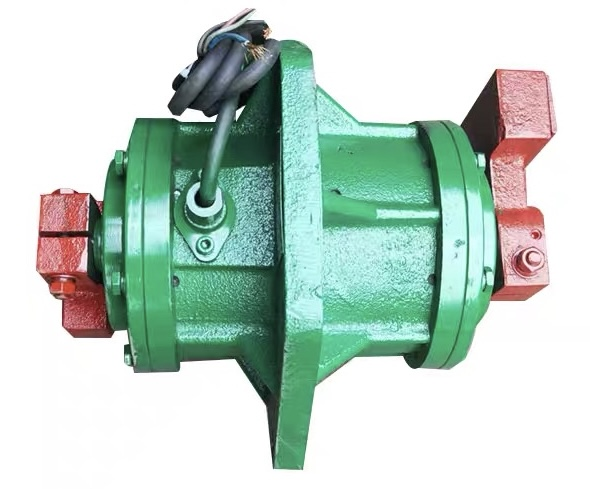

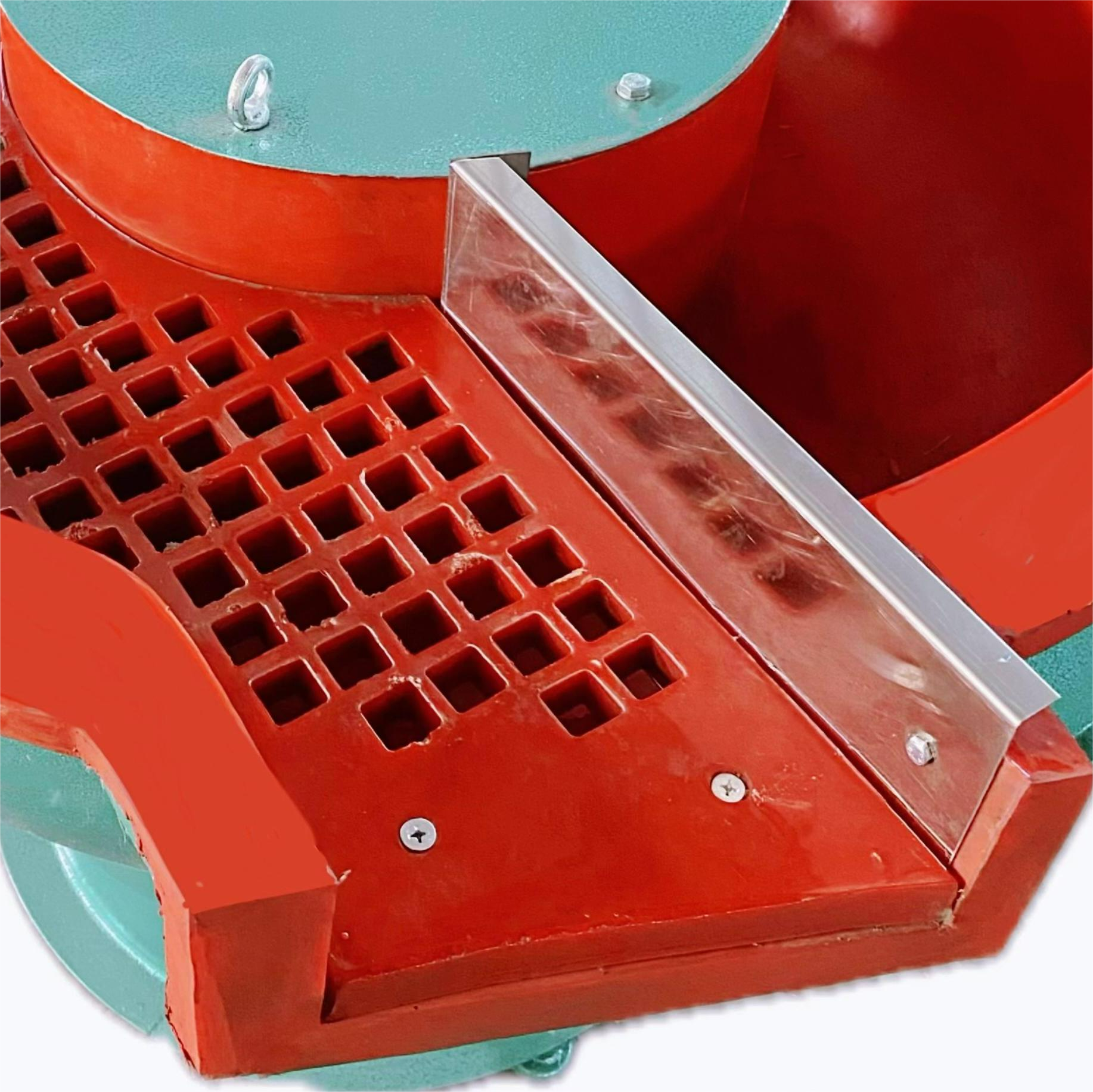

In the structure mainly includes inertial vibrator, vessel and basement. It features a climbing plate with holes and withdrawal on the inside of the machine. It needs to be taken out during the grinding process. After your products meets the polishing requirements, it needs to be put into the shipment portion. And then the products and tumbling polishing media will be automatically separated.

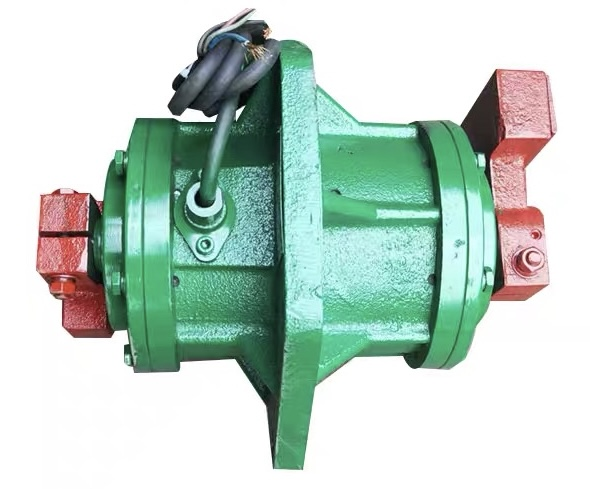

Norden machinery has been committed to producing high performance polishing products to bring happy shopping experience to every customer. We have been trying to develop a better polishing machine. The whole machine steel plate is thickened to make the machine stability is better. The load capacity is significantly improved to keep the machine shell is not easy to crack. The machine is made of high wear-resistant and corrosion-resistant material. This material can extend the service life while avoiding collisions between parts and reducing noise. Our machine can achieve automation, unmanned operation. In the process of polishing, you can check the parts condition at any time.

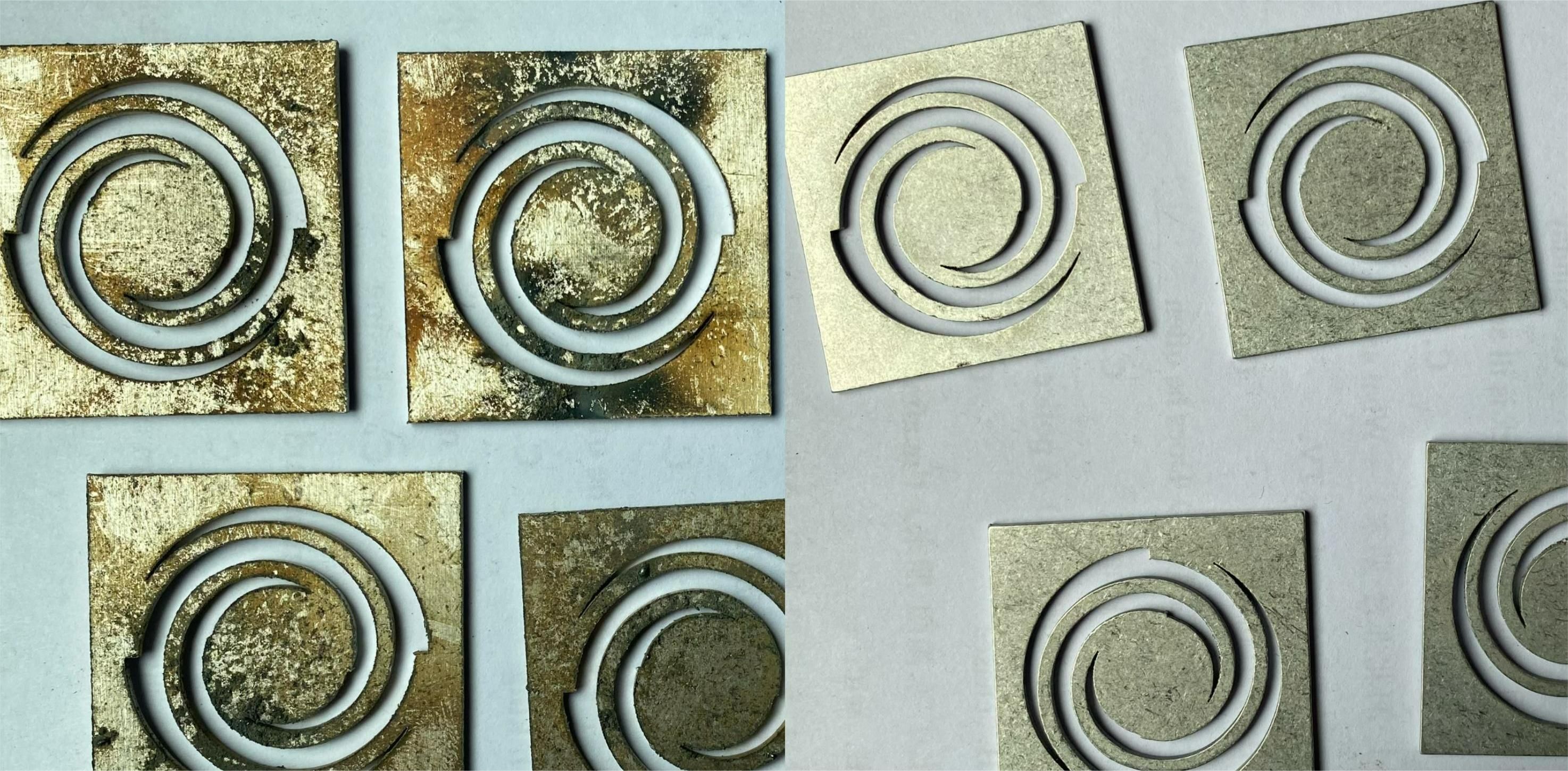

PU Internal Liner

Pure Copper Motor

Thickened Steel Plate

No Damage To Parts

| Feature

1. Automatic separation of tumbling polishing abrasive and products.

2. Large loading capacity and wide application range.

3. Obviously improve the surface finish and precision of the parts.

4. Does not destroy the original size and shape of your product.

5. Suitable for batch small and medium size parts polishing processing.

|

Application

Vibratory polishing machine with separator cover can be applied to the surface polishing, chamfering, deburring, polishing and brightening of various size parts in mass production. It does not affect the original dimensional accuracy of the product after treatment. It also can eliminate the internal stress of the parts and provide the surface finish of the product.This lays a good foundation for some products subsequent electroplating, spraying and other surface treatment.

1. Jewelry polishing, such as pendants, earrings, necklaces, rings, chains, bracelets, pearls, silverware.

2. Cutlery polishing, such as spoons, forks and knives.

3. Rust removal and deburring hardware tools

4. Electronic components finishing

5. Plastic deburring

6. Ceramic jade polishing

7. Laser cut parts polishing

8. 3D print parts polishing

9. ...

|

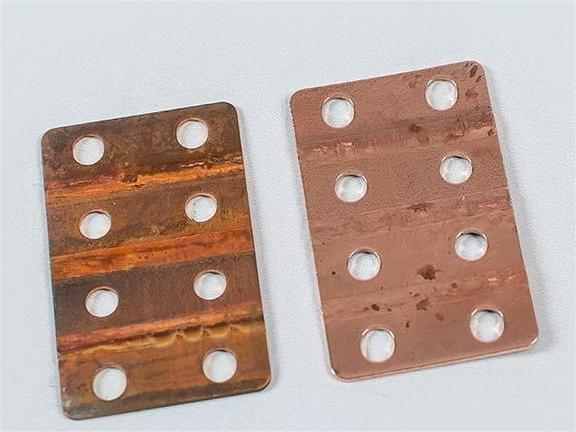

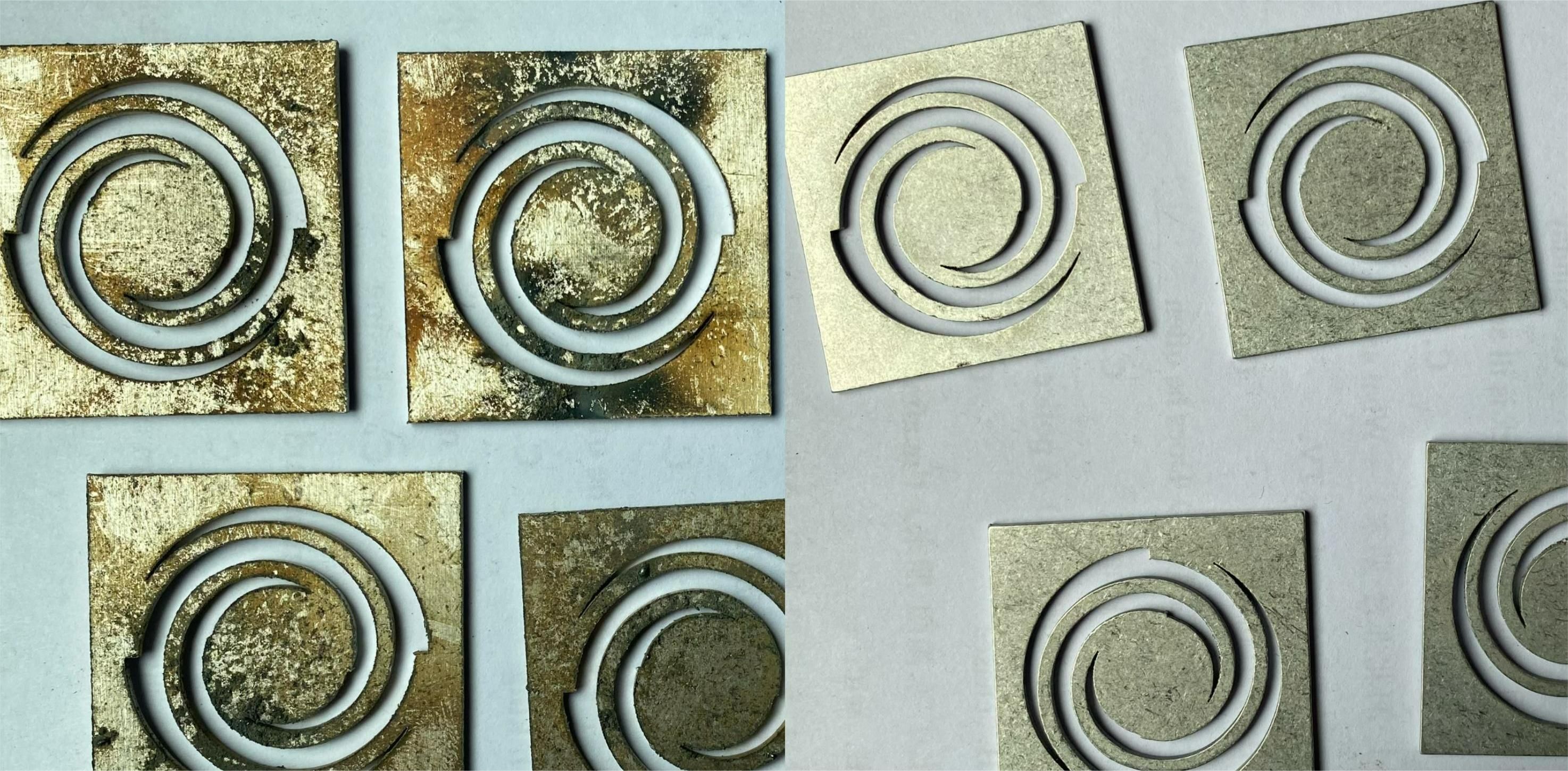

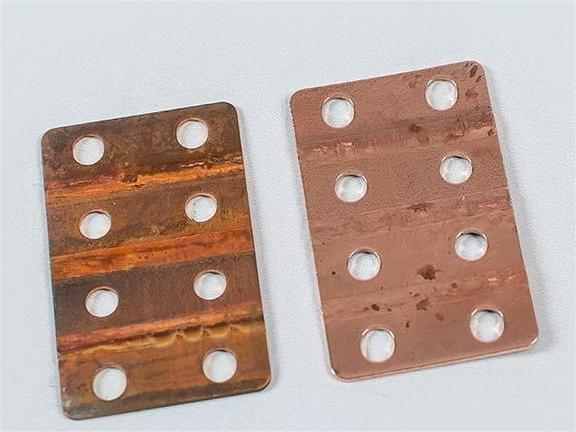

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general product parameter information we can provide. If you have other size requirements, please contact us.

Vibratory Polishing Machine with Separator

Size Parameter Picture

| Model | 150AB | 250AB | 350AB | 450AB | 650AB |

| Total volume(L) | 150 | 250 | 350 | 450 | 650 |

| A(CM) | 110 | 118 | 140 | 152 | 189 |

| A2(CM) | 103 | 115 | 134 | 145 | 180 |

| H1(CM) | 87 | 94 | 102 | 108 | 145 |

| H2(CM) | 30 | 35 | 36 | 40 | 48 |

| ΦB(CM) | 45 | 52 | 62 | 62 | 89 |

| ΦC(CM) | 23 | 29 | 29 | 34 | 40 |

| D(CM) | 25 | 35 | 40 | 45 | 52 |

| E(CM) | 23 | 29 | 34 | 36 | 40 |

| Weight(KG) | 250 | 300 | 500 | 580 | 1450 |

| Box weight(kg) | 50 | 60 | 70 | 80 | 150 |

| Package dimensions(CM) | 120*120*115 | 135*135*120 | 140*140*125 | 152*152*135 | 220*220*175 |

Curved Vibratory Polishing Machine with Separator

Size Parameter Picture

Size Parameter Picture

| Model | B150 | B350 | B650 |

| Total volume(L) | 150 | 350 | 650 |

| A(CM) | 110 | 140 | 189 |

| A2(CM) | 103 | 134 | 176 |

| H1(CM) | 87 | 102 | 145 |

| H2(CM) | 30 | 36 | 50 |

| ΦB(CM) | 45 | 62 | 89 |

| ΦC(CM) | 23 | 29 | 39 |

| D(CM) | 35 | 40 | 40 |

| E(CM) | 23 | 29 | 38 |

| Weight(KG) | 280 | 550 | 1500 |

| Box weight(kg) | 50 | 70 | 150 |

| Package dimensions(CM) | 107*107*93 | 136*136*115 | 220*220*175 |

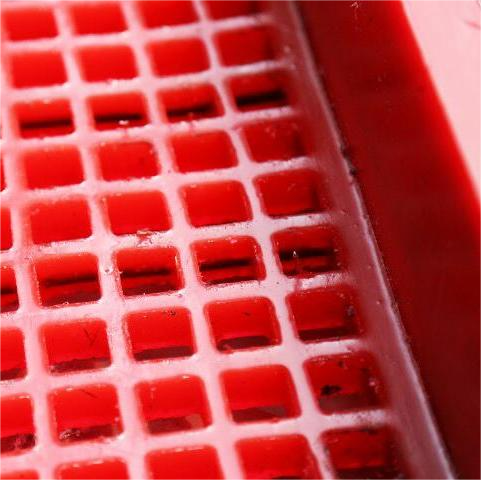

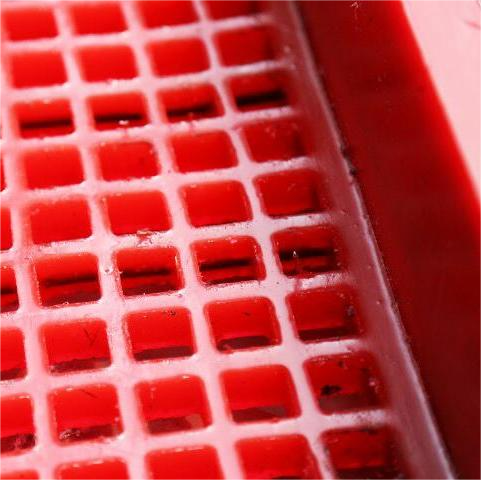

Customization

Norden machinery has been developing and producing polishing machines for more than 20 years. We can provide you with product customization services.The color of the outside of the machine is green, and the PU material inside is red. If you have any special color or shape customization needs, please can contact us. We will try our best to meet your needs.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Vibratory polishing machine with separator works on the similar working principle with normal vibratory polishing machine. It adopts the principle of generating three-dimensional high-frequency vibrations within a ring chamber. These vibrations cause the parts and the tumbling polishing media to move in one direction, resulting in friction that facilitates surface grinding. We can provide you the general vibratory polishing machine with separator and curved vibratory polishing machine with separator.

Vibratory Polishing Machine with Separator

Curved Vibratory Polishing Machine with Separator

In the structure mainly includes inertial vibrator, vessel and basement. It features a climbing plate with holes and withdrawal on the inside of the machine. It needs to be taken out during the grinding process. After your products meets the polishing requirements, it needs to be put into the shipment portion. And then the products and tumbling polishing media will be automatically separated.

Norden machinery has been committed to producing high performance polishing products to bring happy shopping experience to every customer. We have been trying to develop a better polishing machine. The whole machine steel plate is thickened to make the machine stability is better. The load capacity is significantly improved to keep the machine shell is not easy to crack. The machine is made of high wear-resistant and corrosion-resistant material. This material can extend the service life while avoiding collisions between parts and reducing noise. Our machine can achieve automation, unmanned operation. In the process of polishing, you can check the parts condition at any time.

PU Internal Liner

Pure Copper Motor

Thickened Steel Plate

No Damage To Parts

| Feature

1. Automatic separation of tumbling polishing abrasive and products.

2. Large loading capacity and wide application range.

3. Obviously improve the surface finish and precision of the parts.

4. Does not destroy the original size and shape of your product.

5. Suitable for batch small and medium size parts polishing processing.

|

Application

Vibratory polishing machine with separator cover can be applied to the surface polishing, chamfering, deburring, polishing and brightening of various size parts in mass production. It does not affect the original dimensional accuracy of the product after treatment. It also can eliminate the internal stress of the parts and provide the surface finish of the product.This lays a good foundation for some products subsequent electroplating, spraying and other surface treatment.

1. Jewelry polishing, such as pendants, earrings, necklaces, rings, chains, bracelets, pearls, silverware.

2. Cutlery polishing, such as spoons, forks and knives.

3. Rust removal and deburring hardware tools

4. Electronic components finishing

5. Plastic deburring

6. Ceramic jade polishing

7. Laser cut parts polishing

8. 3D print parts polishing

9. ...

|

Polishing Comparison

POLISHING

RUST REMOVAL

RUST REMOVAL

POLISHING

POLISHING

DENURRING

DENURRING

DENURRING

RUST REMOVAL

RUST REMOVAL

|

Size Information

Here is the general product parameter information we can provide. If you have other size requirements, please contact us.

Vibratory Polishing Machine with Separator

Size Parameter Picture

| Model | 150AB | 250AB | 350AB | 450AB | 650AB |

| Total volume(L) | 150 | 250 | 350 | 450 | 650 |

| A(CM) | 110 | 118 | 140 | 152 | 189 |

| A2(CM) | 103 | 115 | 134 | 145 | 180 |

| H1(CM) | 87 | 94 | 102 | 108 | 145 |

| H2(CM) | 30 | 35 | 36 | 40 | 48 |

| ΦB(CM) | 45 | 52 | 62 | 62 | 89 |

| ΦC(CM) | 23 | 29 | 29 | 34 | 40 |

| D(CM) | 25 | 35 | 40 | 45 | 52 |

| E(CM) | 23 | 29 | 34 | 36 | 40 |

| Weight(KG) | 250 | 300 | 500 | 580 | 1450 |

| Box weight(kg) | 50 | 60 | 70 | 80 | 150 |

| Package dimensions(CM) | 120*120*115 | 135*135*120 | 140*140*125 | 152*152*135 | 220*220*175 |

Curved Vibratory Polishing Machine with Separator

Size Parameter Picture

Size Parameter Picture

| Model | B150 | B350 | B650 |

| Total volume(L) | 150 | 350 | 650 |

| A(CM) | 110 | 140 | 189 |

| A2(CM) | 103 | 134 | 176 |

| H1(CM) | 87 | 102 | 145 |

| H2(CM) | 30 | 36 | 50 |

| ΦB(CM) | 45 | 62 | 89 |

| ΦC(CM) | 23 | 29 | 39 |

| D(CM) | 35 | 40 | 40 |

| E(CM) | 23 | 29 | 38 |

| Weight(KG) | 280 | 550 | 1500 |

| Box weight(kg) | 50 | 70 | 150 |

| Package dimensions(CM) | 107*107*93 | 136*136*115 | 220*220*175 |

Customization

Norden machinery has been developing and producing polishing machines for more than 20 years. We can provide you with product customization services.The color of the outside of the machine is green, and the PU material inside is red. If you have any special color or shape customization needs, please can contact us. We will try our best to meet your needs.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case