- Home

- Machine

- Media

- Application

- Service

- About Us

- Blogs

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ND-01

Norden

|

Product Description

Norden machinery has been committed to producing all kinds of finishing machines for more than 20 years. We have rich manufacturing experience and designing polishing machines. Our wheel vibratory polishing machines have high performance. They are perfect for wheel surface grinding, smoothing, polishing, and cleaning.

With the compact design, wheel vibratory polishing machine has a small footprint and is easy to deliver. Also, this machine is extremely user-friendly. You can discharge the polishing tumbling media and load new types of polishing media in a short time. With a combination using of tumbling finishing media ball, you will receive a mirror finish on your wheels just in a few hours.

| Feature

1. High efficient processing. Polishing a car wheel hub takes only 2-5 minutes.

2. Small floor area, easy to deliver.

3. Beautiful shape, foot pedal embedded with the basement, motor hidden in the frame.

4. High cost performance, economical price.

5. Easy to operate and easy to repair.

6. Fully automatic and all-round 360 degrees without dead angle.

|

Application

Wheel hubs are in great demand in the global market. Most common wheel hubs are made of aluminum alloy materials. The high precision polishing results can ensure maximum efficiency. So proper polishing is essential before they are used. Wheel vibratory polishing machine from Norden machinery which can polish them perfectly without any damages. Most car wheels on the market can use this machine to polishing. Whether truck wheels, motorbike wheels, bicycle wheels, automotive wheels, ceramic wheels, mag wheels, alloy wheels, or car wheels. You may also use some suitable tumbling polishing media together to help you get the most satisfactory results.

Motorbike Wheels Polishing

Bicycle Wheels Polishing

Truck Wheels Polishing

Alloy Wheels Polishing

|

Polishing Effect Display

|

Size Information

Here is the general wheel polishing machine parameter information.We truly hope that our wheel polishing machine can help you in your business.

| RIM SIZE | 12“-24” |

| BARREL DIAMETER | 960MM |

| QTY FOR MEDIA | 350KG/BARREL |

| MEDIA FOR DULL GRINDING/CLEANING | 5MM-6MM |

| MEDIA FOR FINE POLSHING/BUFFING | 3-3.5MM |

| VOLTAGE | 220V/380V;50HZ/60HZ;1PH/3PH |

| MOTOR POWER | MAIN SHAFT MOTOR:1.5KW BARREL MOTOR:1.1KW |

| N.W. | 350KG (NO ABRASIVE) |

| PACKING SIZE | 1000*1800*1800MM |

We can also provide you with the following machines:

WHEEL VIBRATORY POLISHING MACHINE

Method of using

Wheel hub polishing machine is simple and convenient to use, the specific steps are as follows:

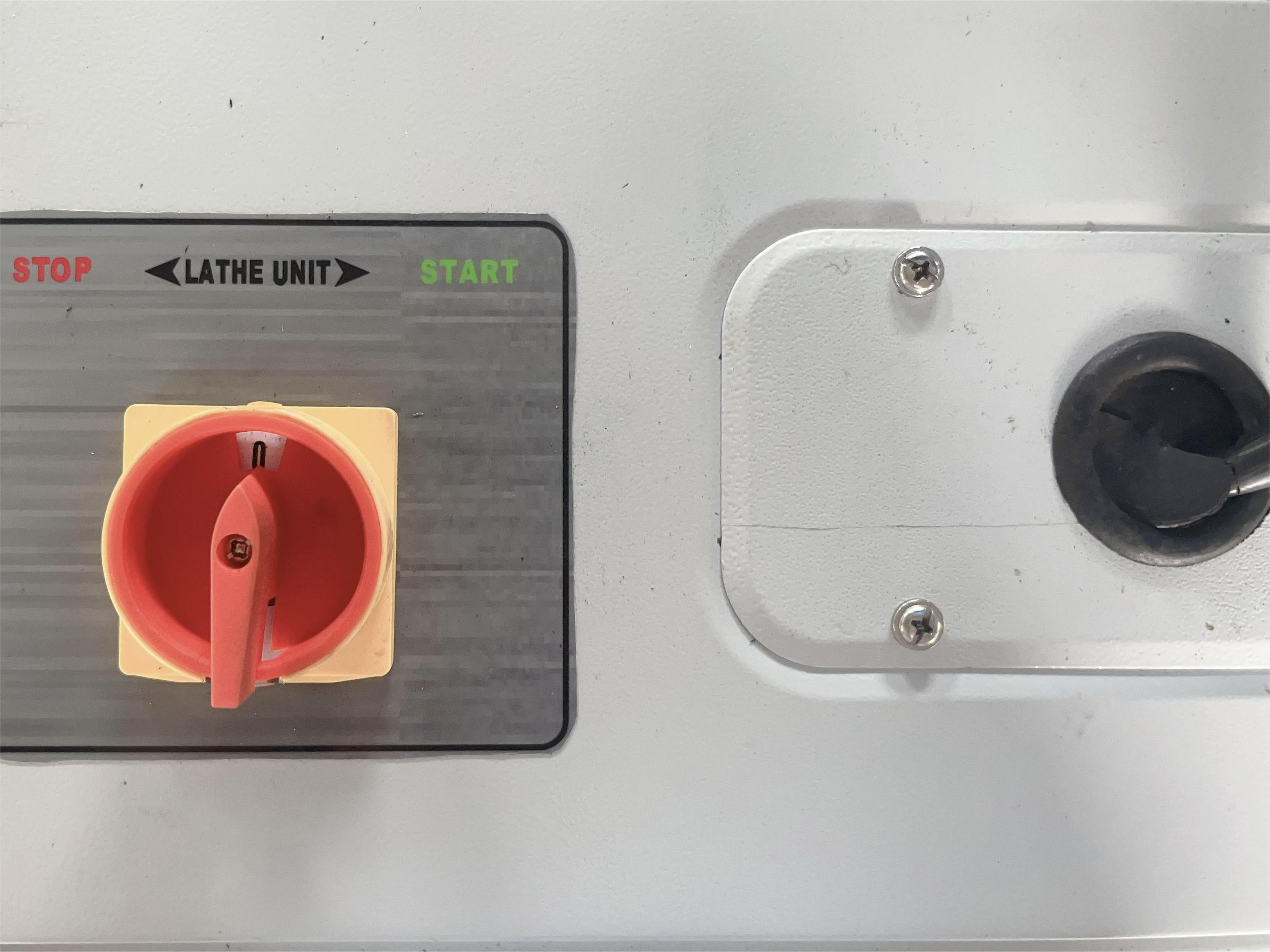

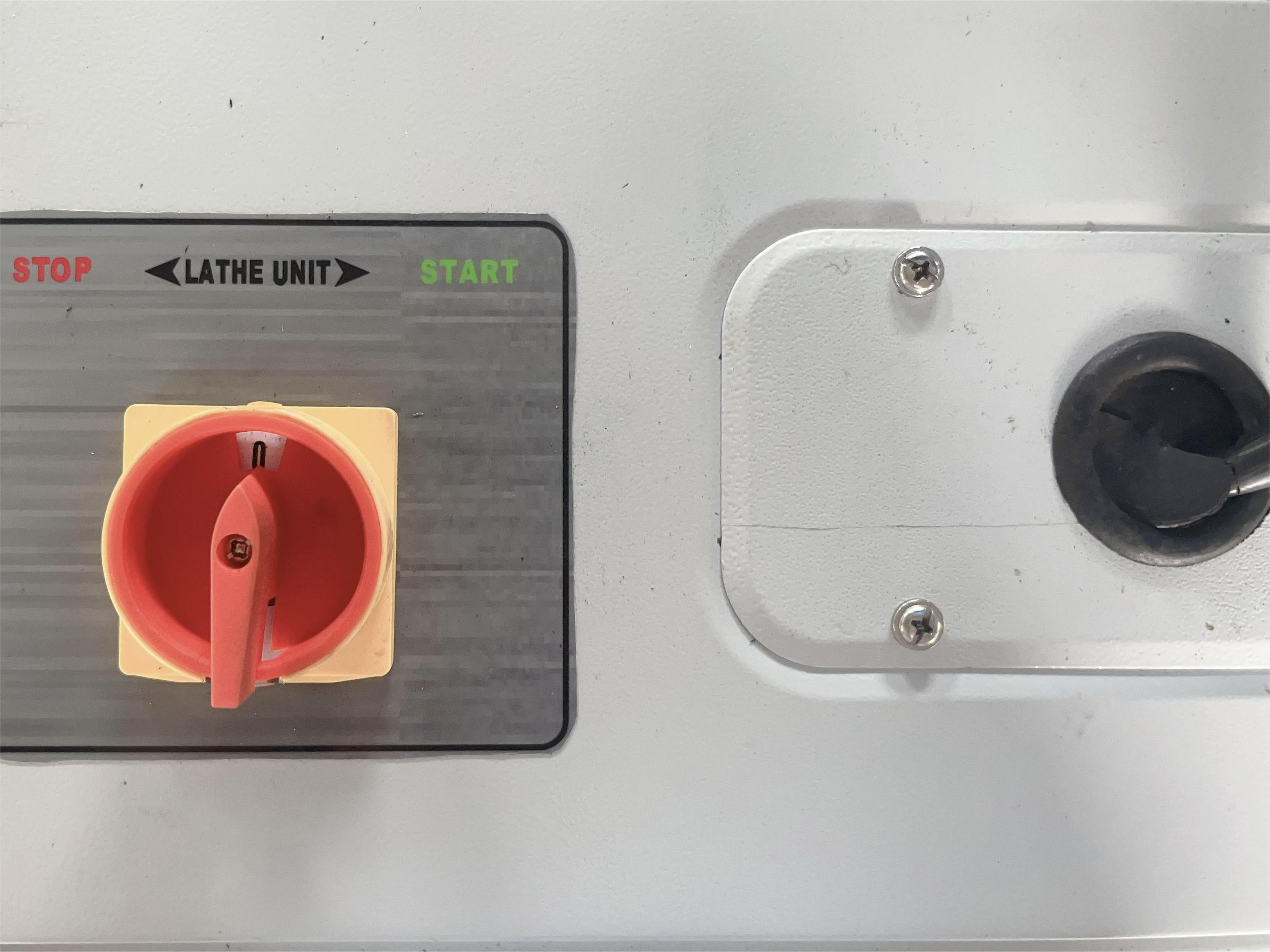

Turn on the power switch and the indicator light will light up. Plug in the air source.

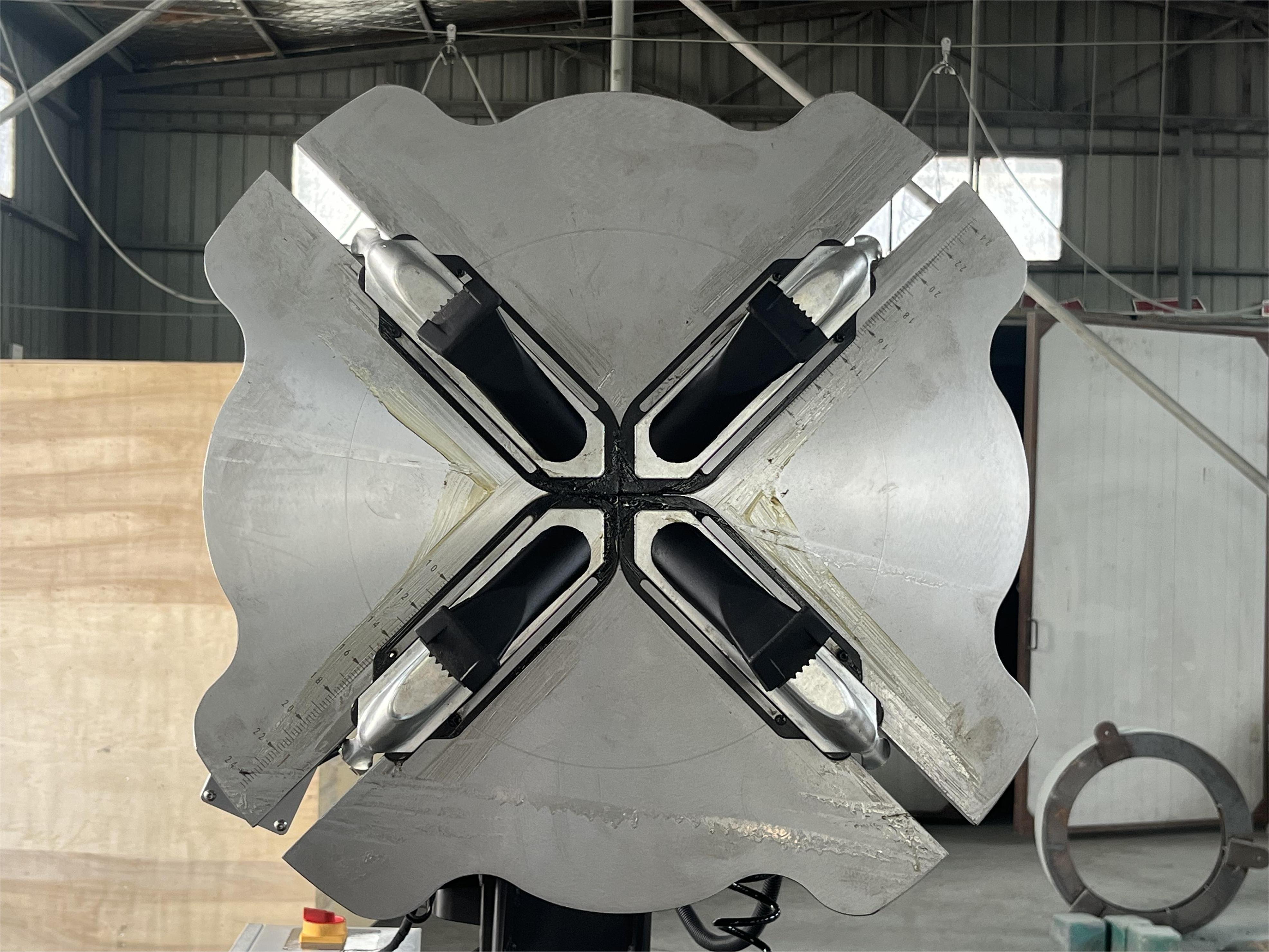

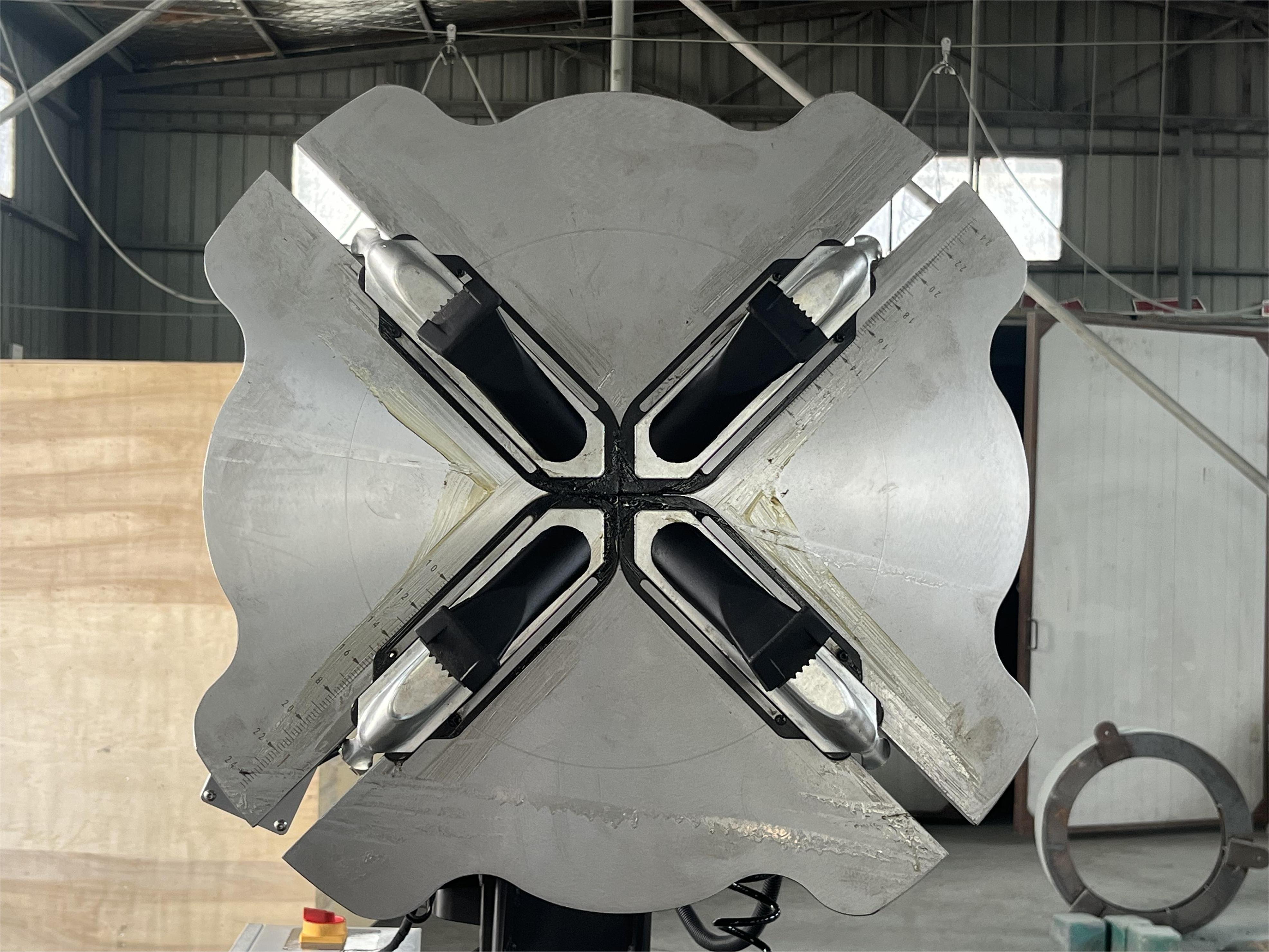

Clamp the steel ring to be repaired onto the large plate, either internally or externally supported, controlled by a foot switch.

Put the abrasive into a white steel bucket, and if it is grinding, add grinding material and cleaning agent. Add a certain proportion of water, and the height of the abrasive should reach 3/4 of the bucket.

Turn on the work disc switch, set a direction, regardless of forward or reverse rotation, and then turn on the abrasive switch. The forward or reverse rotation follows the direction of the work disc, and it works in the opposite direction to the work disc. The working time can be set to 3-5 minutes according to the situation of the rim, and then work in the opposite direction for another 3-5 minutes.

Remove the steel ring, clean the abrasive material with an air gun, clean the steel ring with water, and then spray paint or wheel repair.

The polishing method is the same as the cleaning method, by replacing the abrasive with polishing material and brightening agent.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case

|

Product Description

Norden machinery has been committed to producing all kinds of finishing machines for more than 20 years. We have rich manufacturing experience and designing polishing machines. Our wheel vibratory polishing machines have high performance. They are perfect for wheel surface grinding, smoothing, polishing, and cleaning.

With the compact design, wheel vibratory polishing machine has a small footprint and is easy to deliver. Also, this machine is extremely user-friendly. You can discharge the polishing tumbling media and load new types of polishing media in a short time. With a combination using of tumbling finishing media ball, you will receive a mirror finish on your wheels just in a few hours.

| Feature

1. High efficient processing. Polishing a car wheel hub takes only 2-5 minutes.

2. Small floor area, easy to deliver.

3. Beautiful shape, foot pedal embedded with the basement, motor hidden in the frame.

4. High cost performance, economical price.

5. Easy to operate and easy to repair.

6. Fully automatic and all-round 360 degrees without dead angle.

|

Application

Wheel hubs are in great demand in the global market. Most common wheel hubs are made of aluminum alloy materials. The high precision polishing results can ensure maximum efficiency. So proper polishing is essential before they are used. Wheel vibratory polishing machine from Norden machinery which can polish them perfectly without any damages. Most car wheels on the market can use this machine to polishing. Whether truck wheels, motorbike wheels, bicycle wheels, automotive wheels, ceramic wheels, mag wheels, alloy wheels, or car wheels. You may also use some suitable tumbling polishing media together to help you get the most satisfactory results.

Motorbike Wheels Polishing

Bicycle Wheels Polishing

Truck Wheels Polishing

Alloy Wheels Polishing

|

Polishing Effect Display

|

Size Information

Here is the general wheel polishing machine parameter information.We truly hope that our wheel polishing machine can help you in your business.

| RIM SIZE | 12“-24” |

| BARREL DIAMETER | 960MM |

| QTY FOR MEDIA | 350KG/BARREL |

| MEDIA FOR DULL GRINDING/CLEANING | 5MM-6MM |

| MEDIA FOR FINE POLSHING/BUFFING | 3-3.5MM |

| VOLTAGE | 220V/380V;50HZ/60HZ;1PH/3PH |

| MOTOR POWER | MAIN SHAFT MOTOR:1.5KW BARREL MOTOR:1.1KW |

| N.W. | 350KG (NO ABRASIVE) |

| PACKING SIZE | 1000*1800*1800MM |

We can also provide you with the following machines:

WHEEL VIBRATORY POLISHING MACHINE

Method of using

Wheel hub polishing machine is simple and convenient to use, the specific steps are as follows:

Turn on the power switch and the indicator light will light up. Plug in the air source.

Clamp the steel ring to be repaired onto the large plate, either internally or externally supported, controlled by a foot switch.

Put the abrasive into a white steel bucket, and if it is grinding, add grinding material and cleaning agent. Add a certain proportion of water, and the height of the abrasive should reach 3/4 of the bucket.

Turn on the work disc switch, set a direction, regardless of forward or reverse rotation, and then turn on the abrasive switch. The forward or reverse rotation follows the direction of the work disc, and it works in the opposite direction to the work disc. The working time can be set to 3-5 minutes according to the situation of the rim, and then work in the opposite direction for another 3-5 minutes.

Remove the steel ring, clean the abrasive material with an air gun, clean the steel ring with water, and then spray paint or wheel repair.

The polishing method is the same as the cleaning method, by replacing the abrasive with polishing material and brightening agent.

|

Product Factory Real Show

|

Company Profile

Huzhou Norden Machinery has been adhering to the business for more than 20 years. Our company has strong technical force and advanced equipment. We have provided domestic and foreign customers with good products and good services. We also have a wide selection of vibratory finishing machine and grinding media. Our equipment is widely used in machinery, electronics, instrumentation, aerospace, motorcycles, daily hardware, handicrafts, accessories and other processing and manufacturing industries of metal and non-metals.

With the increasing awareness of metal finishing industry is harming the environment,our products can reduce the pollution of production. We adhere to employing eco-friendly manufacturing processes and raw materials that can be used safely and effectively for years. Our qualified engineers will take care of everything from planning your project to the final installation and after-sales care. Welcome domestic and foreign customers to negotiate and we will give you a perfect solution!

|

Delivery

The modes of transport of machines include sea transport and land transport. The nearest ports to our factory are Ningbo and Shanghai. Nordern can customize environmental wooden packing for you. At the same time, it is convenient for you to disassemble. We are able to make the most suitable transport solution according to your specific needs and the dimensions your machine. Whether you need to ship FCL, LCL or bulk, we can provide professional service. During the transportation process, we strictly comply with international transportation regulations. We also provide real-time cargo tracking services, so that you can know the status of the shipment at any time.

Nordern aims to create a hassle-free transportation experience for you. To find out more about our shipping services or to get a quote, please contact our customer service team. Look forward to establishing long-term and stable cooperative relationship with you!

|

Packaging

Wooden Case

Wooden Case

Wooden Case